Stone paper functional master batch with multilayer coating core shell structure and preparation method of stone paper functional master batch

A core-shell structure and multi-layer coating technology, applied in the field of stone paper making, can solve the problem of inability to achieve uniform blending of inorganic fillers and organic carrier resins, increase the amount of coupling agent or dispersant, limit the promotion and application of stone paper, etc. Problems, achieve good practical value and application prospects, improve product quality, broad industrialization and market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: anti-aging stone paper masterbatch

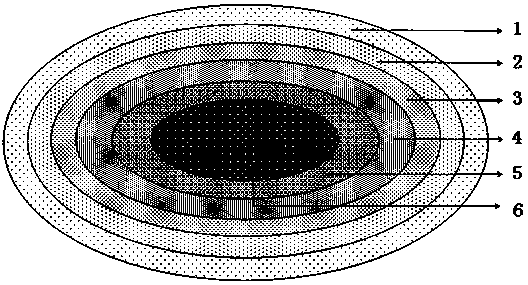

[0033] As shown in the figure, the stone paper functional masterbatch with a multi-layer core-shell structure, the stone paper functional masterbatch consists of an inorganic filler layer 6, a coupling layer 5, a dispersion layer 4, and an increaser in sequence from the core to the shell. Solvent layer 3, functional layer 2 and resin layer 1 constitute.

[0034] The thickness of the inorganic filler layer 6 is 1-13 microns.

[0035] The thickness of the coupling layer 5 is 0.1-1 micron.

[0036] The dispersion layer 4 has a thickness of 0.1-1 micron.

[0037] The thickness of the solubilizing layer 3 is 0.1-2 microns.

[0038] The thickness of the functional layer 2 is 0.1-1 micron.

[0039] The thickness of the resin layer 1 is 2-5 microns.

[0040] (1) Prepare raw materials according to the following mass percentages: 1000 mesh talc powder 55%, triisostearyl titanate 4%, PP wax 2%, PP-g-MAH maleic anhydride graft...

Embodiment 2

[0044] Example 2: Stone paper masterbatch with flame-retardant and anti-corrosion function

[0045] (1) Prepare raw materials according to the following mass percentages: 55% of 1250 mesh magnesium hydroxide and 30% of aluminum hydroxide, 1% of isopropyl dioleate acyloxy titanate, 1% of PE wax, PE-g- MAH maleic anhydride graft 2%, tert-butyl p-hydroxyinherin 1%, HDPE resin 10%;

[0046] (2) Dry the inorganic filler and carrier resin in a vacuum dryer at 125°C for 9 hours;

[0047] (3) Add the inorganic filler and coupling agent to the high-speed mixer, and pre-mix for 6 minutes at a speed of 1250 rpm; then add the dispersant, solubilizer and functional additive to the high-speed mixer in sequence In the kneader, mix the inorganic filler after coupling treatment at 1250 rpm for 6 minutes at a high speed to fully disperse and coat the inorganic filler to obtain a mixture; then mix the carrier resin with the above multi-layer coating and solubilize and disperse After the mixtur...

Embodiment 3

[0049] Example 3: Easily degradable stone paper functional masterbatch

[0050] (1) Prepare raw materials according to the following mass percentages: the components are prepared according to mass percentages: 1500 mesh calcium carbonate powder 75%, titanium dioxide 5%, distearoyloxyisopropyl aluminate 1%, EVA wax 1% %, EVA-g-MAH maleic anhydride graft 3%, phenyl salicylate 1%, ethylene-vinyl acetate copolymer EVA 14%;

[0051] (2) Dry the inorganic filler and carrier resin in a vacuum dryer at 125°C for 10 hours;

[0052] (3) Add the inorganic filler and coupling agent to the high-speed mixer and pre-mix for 6 minutes at a speed of 1500 rpm; then add the dispersant, solubilizer and functional additive to the high-speed mixer in sequence. In the kneader, mix the inorganic filler after coupling treatment at 1500 rpm for 8 minutes at high speed to fully disperse and coat the inorganic filler to obtain a mixture; After the mixture was blended for 5 minutes at 1500 rpm to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com