A concrete 3D printing U-shaped nail automatic nailing system

A 3D printing and concrete technology, applied in the field of 3D printing, can solve the problems that 3D printing concrete is difficult to meet the load-bearing requirements of the project, there is no vertical printing interlayer reinforcement equipment, and the mechanical properties of 3D printing components are weakened, so as to ensure continuous and uninterrupted Sexuality, high degree of automation, to achieve the effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

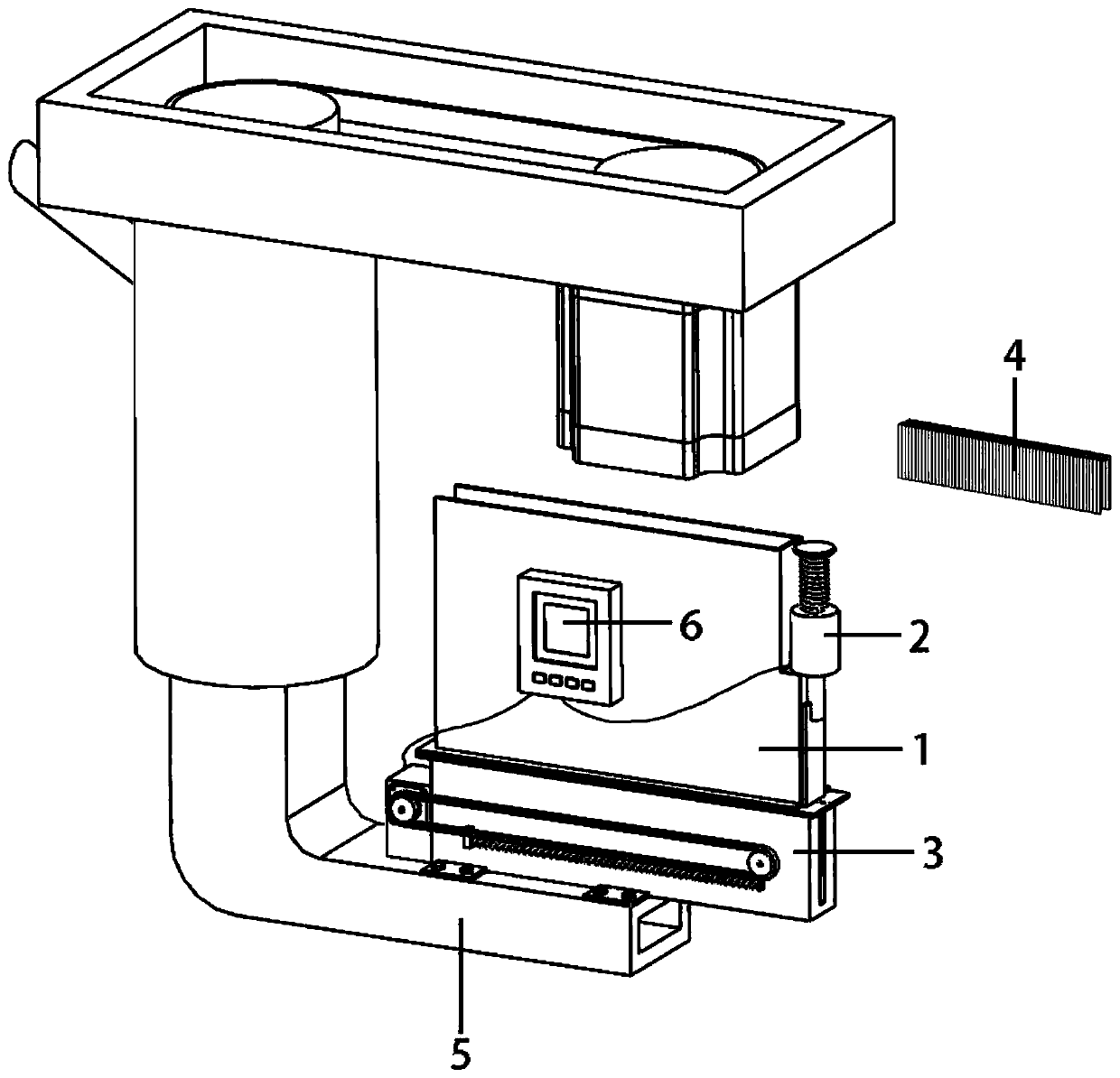

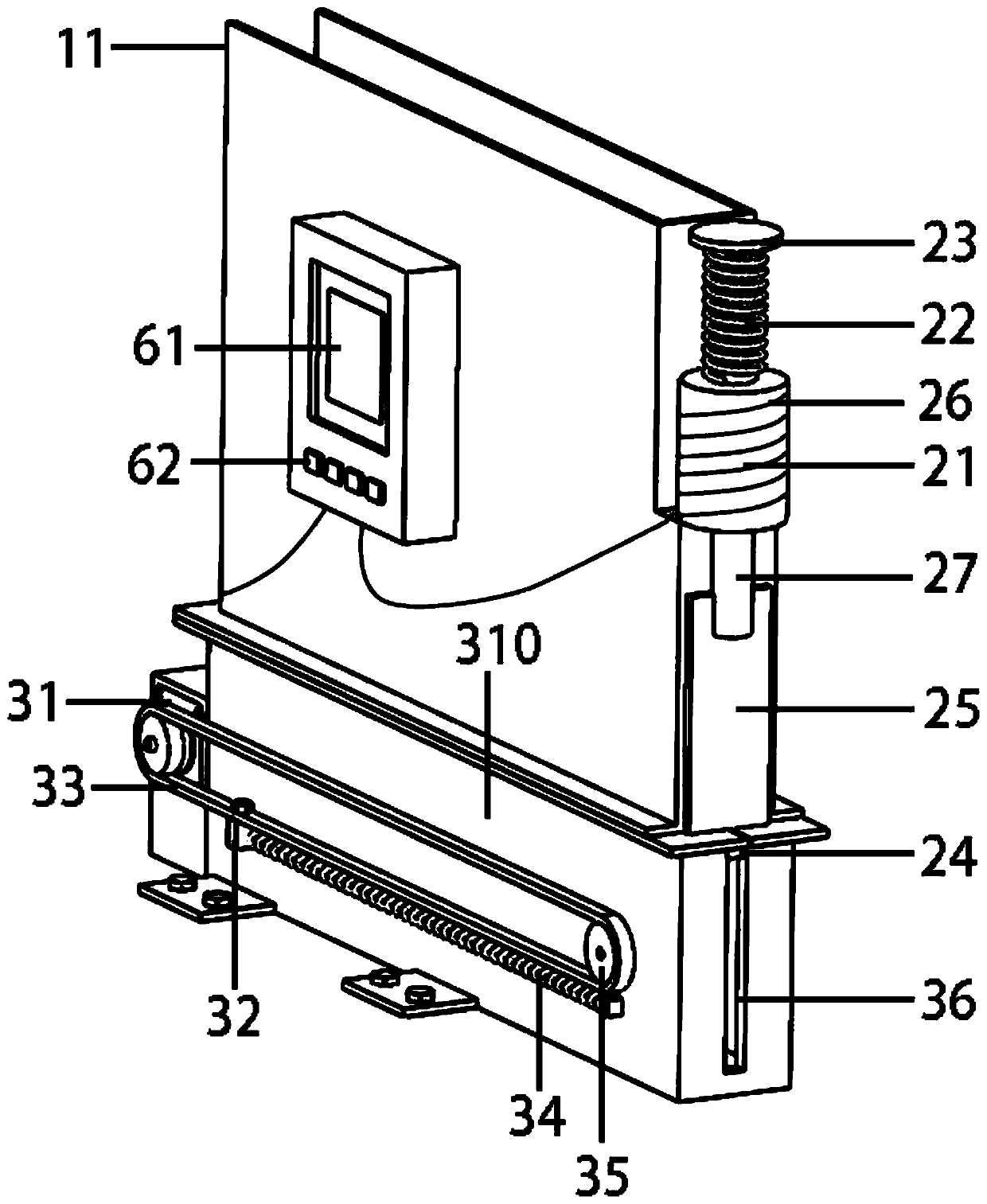

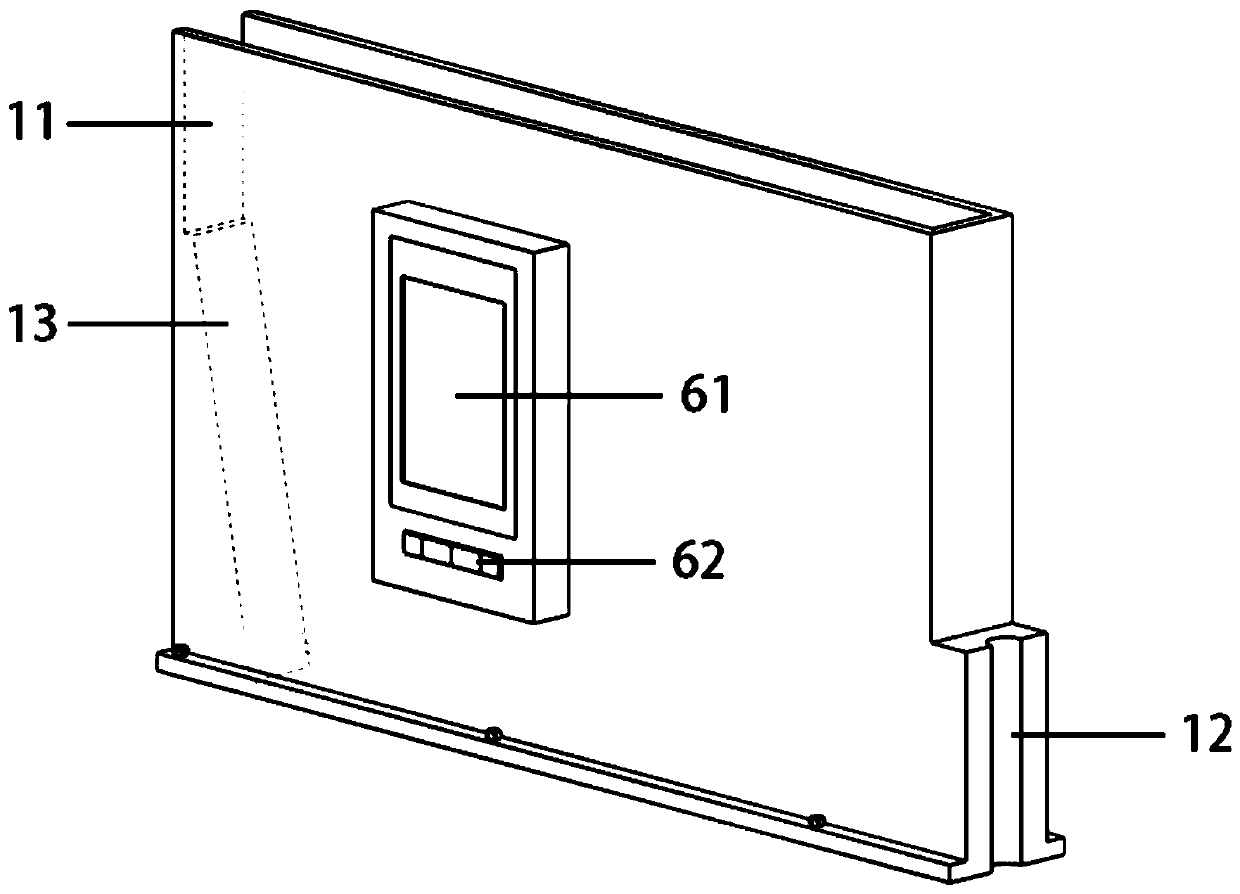

[0031] The present invention provides a concrete 3D printing U-shaped nail automatic placement system (referred to as the nail placement system), which is characterized in that the nail placement system includes a nail storage box 1, a striker mechanism 2, a U-shaped nail transmission mechanism 3 and an electronic control system 6. The striker mechanism 2 includes an electromagnet excitation device 21, a return spring 22, a limiter 23, a striker slider 24 and a striker 25; the staple delivery mechanism 3 includes a conveyor belt motor 31, a conveyor belt 33, and a conveyor spring 34 , conveyor belt runner 35, striker slider track 36, nail outlet 37, nail delivery slider track 38, nail delivery slider 39 and housing 310;

[0032] The bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com