Wave-absorbing coating material and preparation method thereof

A technology of wave absorbing paint and carbonyl iron powder, applied in radiation absorbing paint, epoxy resin paint, polyurea/polyurethane paint, etc. Large constants, etc., to achieve the effect of broadband and absorption performance, good broadband absorption performance, and resistance to complex environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

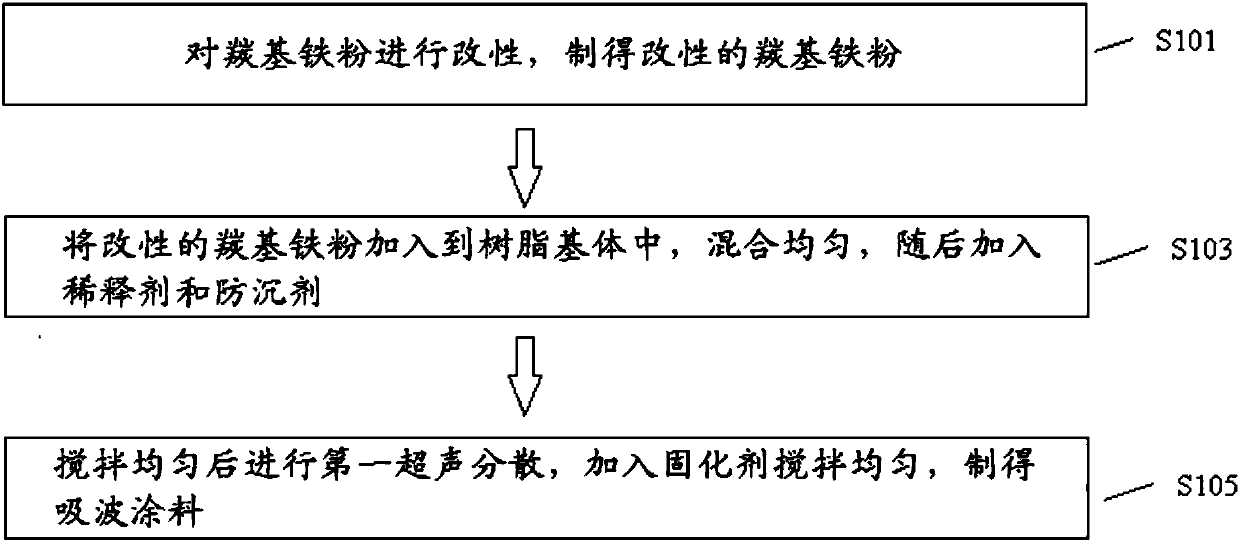

Method used

Image

Examples

Embodiment 1

[0030] Mix the carbonyl iron powder with the silane coupling agent solution, wherein the amount of the silane coupling agent is 6% of the mass of the carbonyl iron powder, and then carry out the second ultrasonic dispersion of the mixed solution in a water bath at 40°C to make the carbonyl iron powder Uniformly dispersed in the silane coupling agent solution, reacted for 40min, after the reaction, the reactant was filtered, washed with deionized water for several times, and dried to obtain carbonyl iron powder particles with organic silane modified surface amination; the surface amination The carbonyl iron powder particles are ground in a ball mill to obtain modified carbonyl iron powder.

[0031] Add 8 parts of modified carbonyl iron powder into 1 part of epoxy resin matrix, mix well, then add 0.8 parts of diluent and 0.2 parts of anti-settling agent. Wherein, the diluent is xylene and the anti-sedimentation agent is titanate coupling agent.

[0032] After stirring evenly, p...

Embodiment 2

[0034] Mix the carbonyl iron powder with the silane coupling agent solution, wherein the amount of the silane coupling agent is 2% of the mass of the carbonyl iron powder, and then ultrasonically disperse the mixed solution in a water bath at 30°C to make the carbonyl iron powder uniform Disperse in the silane coupling agent solution, react for 30min, filter the reactant after the reaction, wash with deionized water several times, and dry to obtain carbonyl iron powder particles with surface amination modified by organosilane; The iron powder particles are ground in a ball mill to obtain modified carbonyl iron powder.

[0035] Add 10 parts of modified carbonyl iron powder into 2 parts of epoxy resin matrix, mix well, then add 0.5 parts of diluent and 0.3 parts of anti-settling agent. The diluent is n-butanol and the anti-sedimentation agent is titanate coupling agent.

[0036] After stirring evenly, perform the first ultrasonic dispersion for 10 hours, add 0.4 parts of curing...

Embodiment 3

[0038] Mix the carbonyl iron powder with the silane coupling agent solution, wherein the amount of the silane coupling agent is 10% of the mass of the carbonyl iron powder, and then carry out the second ultrasonic dispersion of the mixed solution in a water bath at 50°C to make the carbonyl iron powder Uniformly dispersed in the silane coupling agent solution, reacted for 50min, after the reaction, the reactant was filtered, washed with deionized water for several times, and dried to obtain carbonyl iron powder particles with organic silane modified surface amination; the surface amination The carbonyl iron powder particles are ground in a ball mill to obtain modified carbonyl iron powder.

[0039] Add 5 parts of modified carbonyl iron powder to 1.5 parts of epoxy resin matrix, mix well, then add 1 part of diluent and 0.4 parts of anti-settling agent. The diluent is acetone and xylene in any proportion and the anti-sedimentation agent is a titanate coupling agent.

[0040] Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com