Flexible whole-solid-state battery and preparation method of same

An all-solid-state battery and solid-state electrolyte technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of poor flexibility, poor rate performance and high-temperature performance of all-solid-state batteries, and achieve improved conductivity and Liquid retention capacity, good battery rate performance and high temperature performance, and the effect of enhancing ion conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a method for preparing a flexible all-solid-state battery, comprising the following steps:

[0042] (1) Mix and stir the positive electrode active material, conductive adhesive, binder, first solid electrolyte, first cellulose matrix and solvent to form a uniformly dispersed slurry, and pour the resulting slurry into a suction filter with filter paper In the device, it is filtered to form a film to prepare a flexible positive electrode sheet.

[0043] (2) Mix and stir the negative electrode active material, conductive adhesive, binder, first solid electrolyte, first cellulose matrix and solvent to form a uniformly dispersed slurry, and pour the resulting slurry into a suction filter with filter paper In the device, the film is formed by filtration to prepare a flexible negative electrode sheet.

[0044] (3) Fully mix and high-speed disperse the second solid electrolyte in the solvent, then add the second cellulose matrix that has bee...

Embodiment 1

[0058] (1) Put the active material graphite raw material, the conductive agent carbon nanotube, the solid electrolyte polyethylene oxide, and the nanocellulose matrix into the isopropanol solvent with a mass ratio of 87:3:5:5. Stir at high speed at room temperature for 15 minutes to obtain a viscous slurry, pour the resulting viscous slurry into a suction filter with filter paper, filter to form a film, and vacuum dry at 130°C for 8 hours to obtain a flexible negative electrode After the dried flexible negative electrode sheet was rolled on a roller press, a flexible negative electrode sheet with a thickness of 100 microns was obtained.

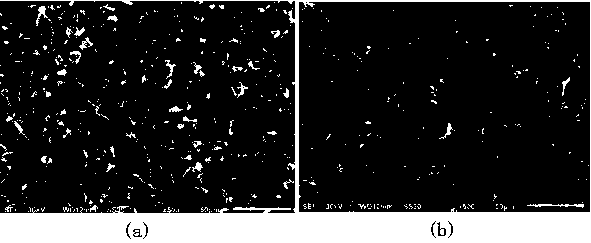

[0059] The flexible negative electrode sheet obtained in this embodiment has good flexibility and can be bent repeatedly without breaking. figure 1 It is the electron microscope picture of the flexible negative electrode sheet before and after rolling. It can be seen from the figure that the active material and the active material are surroun...

Embodiment 2

[0067] (1) The active material lithium cobalt oxide raw material, the conductive agent carbon nanotube, and the solid electrolyte Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 Put the three substances into the isopropanol solvent with a mass ratio of 92:3:5, stir at high speed for 10 minutes at room temperature to form a uniformly dispersed suspension, and add the fully dispersed cellulose base liquid to the suspension , the cellulose accounted for 8% of the entire pole piece, stirred again at high speed for 5 minutes to obtain a viscous slurry, poured the obtained viscous slurry into a suction filter device with filter paper, filtered to form a film, and heated at 120°C , dried in vacuum for 12 hours to prepare a flexible positive electrode sheet, and rolled the dried flexible positive electrode sheet on a roller press to obtain a flexible positive electrode sheet with a thickness of 110 microns.

[0068] The flexible positive electrode sheet obtained in this example has good flexibilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com