A composite packaging integrated functional solar battery backplane

A solar cell and functional technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of EVA replacement layer loss of insulation, edge overflow glue delamination, insulation thickness reduction, etc., to achieve high reflective water permeability, The effect of low water permeability and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

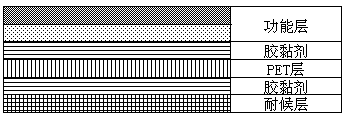

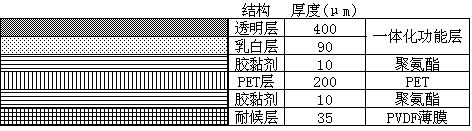

[0034] Such as figure 2 As shown, a composite packaging integrated functional solar cell backsheet disclosed by the present invention is composed of a weather-resistant layer, an adhesive layer, a PET layer, an adhesive layer, and a functional layer from the outside to the inside, and the weather-resistant layer is a PVDF film. , the thickness is 35 μm, the adhesive layer is polyurethane adhesive, the thickness is 10 μm, the thickness of the PTE layer is 200 μm, the functional layer includes a single milky white layer and a single transparent layer, and the milky white layer is glued to the PET layer, and its thickness is 90 μm , consisting of 25 parts of polyethylene, 45 parts of polyolefin elastomer, 19 parts of polyolefin plastomer, 10 parts of titanium dioxide, 0.4 part of antioxidant and 0.6 part of ultraviolet absorber, the transparent layer is bonded to the battery sheet, and its The thickness is 400 μm, and it is composed of 60 parts of polyolefin elastomer, 39 parts ...

no. 2 example

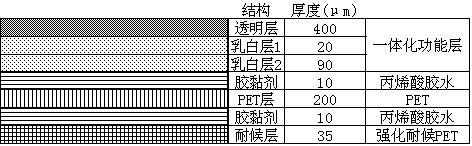

[0037] Such as image 3As shown, a composite packaging integrated functional solar battery backsheet disclosed by the present invention, from the outside to the inside, is a weather-resistant layer, an adhesive layer, a PET layer, an adhesive layer, and a functional layer, wherein the weather-resistant layer is an enhanced weather-resistant PET, the thickness is 35 μm, the adhesive layer is acrylic adhesive, the thickness is 10 μm, and the thickness of the PET layer is 200 μm. 25 parts, 45 parts of polyolefin elastomer, 19 parts of polyolefin plastomer, 10 parts of titanium dioxide, 0.4 parts of antioxidant and 0.6 parts of ultraviolet absorber, the thickness of the upper milky white layer is 20 μm, composed of 29 parts of polyethylene, polyolefin 55 parts of elastomer, 5 parts of polyolefin plastic body, 10 parts of titanium dioxide, 0.4 parts of antioxidant and 0.6 parts of ultraviolet absorber. 60 parts, composed of 39 parts of ethylene-vinyl acetate copolymer, 0.4 part of...

no. 3 example

[0040] Such as Figure 4 As shown, a composite packaging integrated functional solar cell backsheet disclosed by the present invention is composed of a weather-resistant layer, an adhesive layer, a PET layer, an adhesive layer, and a functional layer from the outside to the inside, and the weather-resistant layer is a PVDF film. , the thickness is 35 μm, the adhesive layer is polyurethane adhesive, the thickness is 10 μm, the thickness of the PTE layer is 200 μm, the functional layer includes a single layer of milky white layer and a double layer of transparent layer, wherein the thickness of the milky white layer is 100 μm, made of 25 parts of polyethylene , 45 parts of polyolefin elastomer, 19 parts of polyolefin plastic body, 10 parts of titanium dioxide, 0.4 parts of antioxidant and 0.6 parts of ultraviolet absorber, the thickness of the lower transparent layer is 400 μm, composed of 60 parts of polyolefin elastomer, ethylene- Composed of 39 parts of vinyl acetate copolyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com