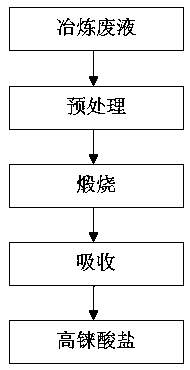

Method for recovering rhenium from metallurgical waste liquid

A technology for waste liquid and filtrate, applied in the direction of improving process efficiency, can solve the problems of volatile, high investment cost, and large environmental pollution, and achieve the effect of efficient recovery, wide source and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

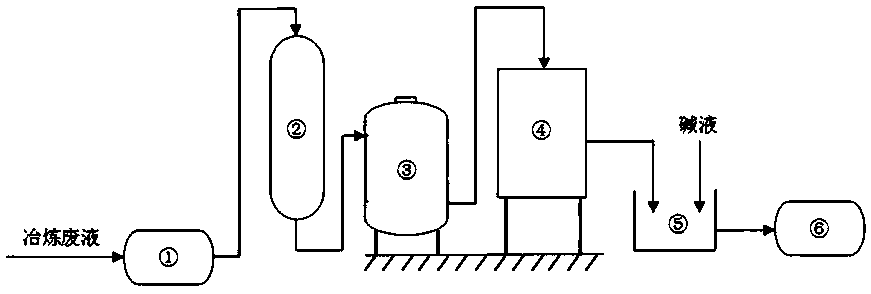

Method used

Image

Examples

Embodiment 1

[0022] Using the smelting waste liquid provided by the copper smelter as raw material, the smelting waste liquid contains 260 mg / L of copper, 194 mg / L of magnesium, 204 mg / L of iron, 0.65 mg / L of rhenium and 7944 mg / L of sulfuric acid. L.

[0023] Add a precipitating agent (mixed by calcium hydroxide and calcium oxide in a weight ratio of 4:1) to the rhenium-containing smelting waste liquid until the pH of the solution is 9, press filter to separate, collect the filtrate, adjust the pH to 5~7, and put The filtrate passes through the biochar adsorption tower with an adsorption temperature of 15°C and a pH of 6 to further adsorb coexisting ions; then enters the stirring tank, and adds biochar to adsorb rhenium. When the adsorption reaches saturation, stop the adsorption and press filter to separate; The cake was sent to a rotary calciner for calcination. The calcination temperature was 550°C, the heating rate was 10°C / min, and the calcination time was 6 h. It was absorbed with 0...

Embodiment 2

[0025] Using the smelting waste liquid provided by the molybdenum smelter as raw material, the smelting waste liquid contains 520 mg / L copper, 980 mg / L molybdenum, 146 mg / L iron, 26 mg / L rhenium and 56870 mg / L sulfuric acid. L.

[0026] Add a precipitating agent (mixed by calcium hydroxide and calcium oxide at a weight ratio of 2:1) to the rhenium-containing smelting waste liquid until the pH of the solution is 10, press filter to separate, collect the filtrate, adjust the pH to 5~7, and put The filtrate passes through the biochar adsorption tower with an adsorption temperature of 20°C and a pH of 5 to further absorb coexisting ions; then enters the stirring tank, and adds biochar to adsorb rhenium. When the adsorption reaches saturation, stop the adsorption and press filter to separate; The cake was sent to a rotary calciner for calcination. The calcination temperature was 650°C, the heating rate was 10°C / min, and the calcination time was 8 h. It was absorbed with 1 mol / L amm...

Embodiment 3

[0028] Using the smelting waste liquid provided by the iron smelter as raw material, the smelting waste liquid contains 380 mg / L of copper, 135 mg / L of nickel, 870 mg / L of iron, 0.69 mg / L of rhenium, and 82610 mg / L of sulfuric acid. L.

[0029] Add a precipitating agent (mixed by calcium hydroxide and calcium oxide at a weight ratio of 6:1) to the rhenium-containing smelting waste liquid until the pH of the solution is 11, press filter to separate, collect the filtrate, adjust the pH to 5~7, and put The filtrate passes through the biochar adsorption tower at 25°C and pH 4 to further absorb the coexisting ions; then enters the stirring tank and adds biochar to adsorb rhenium. When the adsorption reaches saturation, the adsorption is stopped and separated by pressure filtration; the filter cake is sent to Calcination in a rotary calciner at a temperature of 750°C, a heating rate of 15°C / min, a calcination time of 8 h, and absorption with a 2 mol / L KOH solution to obtain potassiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com