Recovery technology of tellurium from complex solution through carrier method

A carrier and complex technology, applied in the process field of tellurium recovery by the carrier method, to achieve the effect of simple equipment, large carrier capacity and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

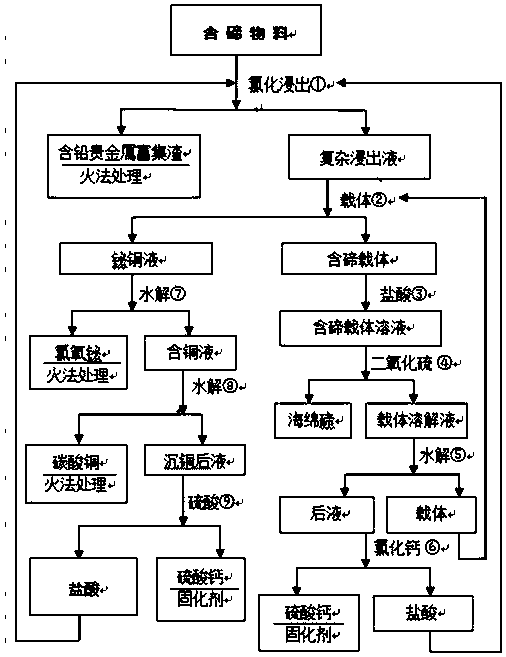

Method used

Image

Examples

Embodiment 1

[0059] The process of recovering tellurium from a complex solution using a carrier method includes the following steps:

[0060] (1) Use tellurium-containing materials as raw materials, according to the liquid-solid ratio of 30L: 10kg, add hydrochloric acid and hydrogen peroxide for oxidative leaching, the concentration of hydrochloric acid is 200g / L, the mass concentration of hydrogen peroxide is 15%, the reaction temperature is 90°C, and the reaction time is 3h After the reaction is completed, the lead-containing precious metal-enriched slag and complex leachate are separated, and the reaction end point is controlled: the tellurium content of the lead-containing precious metal-enriched slag is less than 0.5%, and the terminal potential of the complex leachate is 700mV;

[0061] (2) Add a carrier to the complex leaching solution described in step (1), the added mass of the carrier is 1.5 times the tellurium content in the complex leaching solution, the reaction temperature is ...

Embodiment 2

[0072] The process of recovering tellurium from a complex solution using a carrier method includes the following steps:

[0073] (1) Use tellurium-containing materials as raw materials, add hydrochloric acid and hydrogen peroxide for oxidative leaching according to the liquid-solid ratio of 40L: 10kg, the concentration of hydrochloric acid is 220g / L, the mass concentration of hydrogen peroxide is 16%, the reaction temperature is 95°C, and the reaction time is 2.5h After the reaction is completed, the lead-containing precious metal-enriched slag and the complex leach solution are separated, and the reaction end point is controlled: the tellurium content of the lead-containing precious metal-enriched slag is less than 0.5%, and the terminal potential of the complex leach solution is 720mV;

[0074] (2) Add a carrier to the complex leaching solution described in step (1), the added mass of the carrier is 1.8 times of the tellurium content in the complex leaching solution, the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com