Polyamide foaming material and preparation method of same

A technology of foaming materials and polyamides, which is applied in the field of high molecular polymer material preparation, can solve problems such as limitations in pouring and foaming processes, and achieve the effect of achieving limited foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

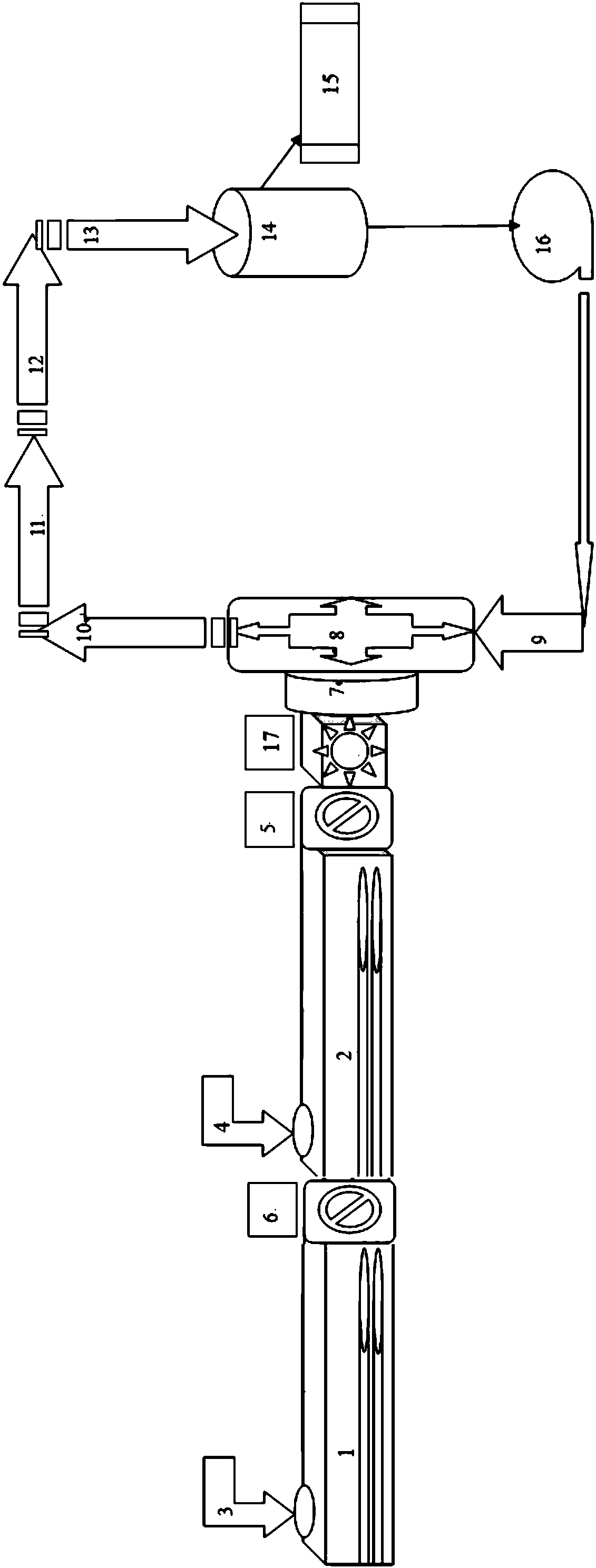

[0057] refer to figure 1 The shown process flow is used to prepare the following polyamide foam materials.

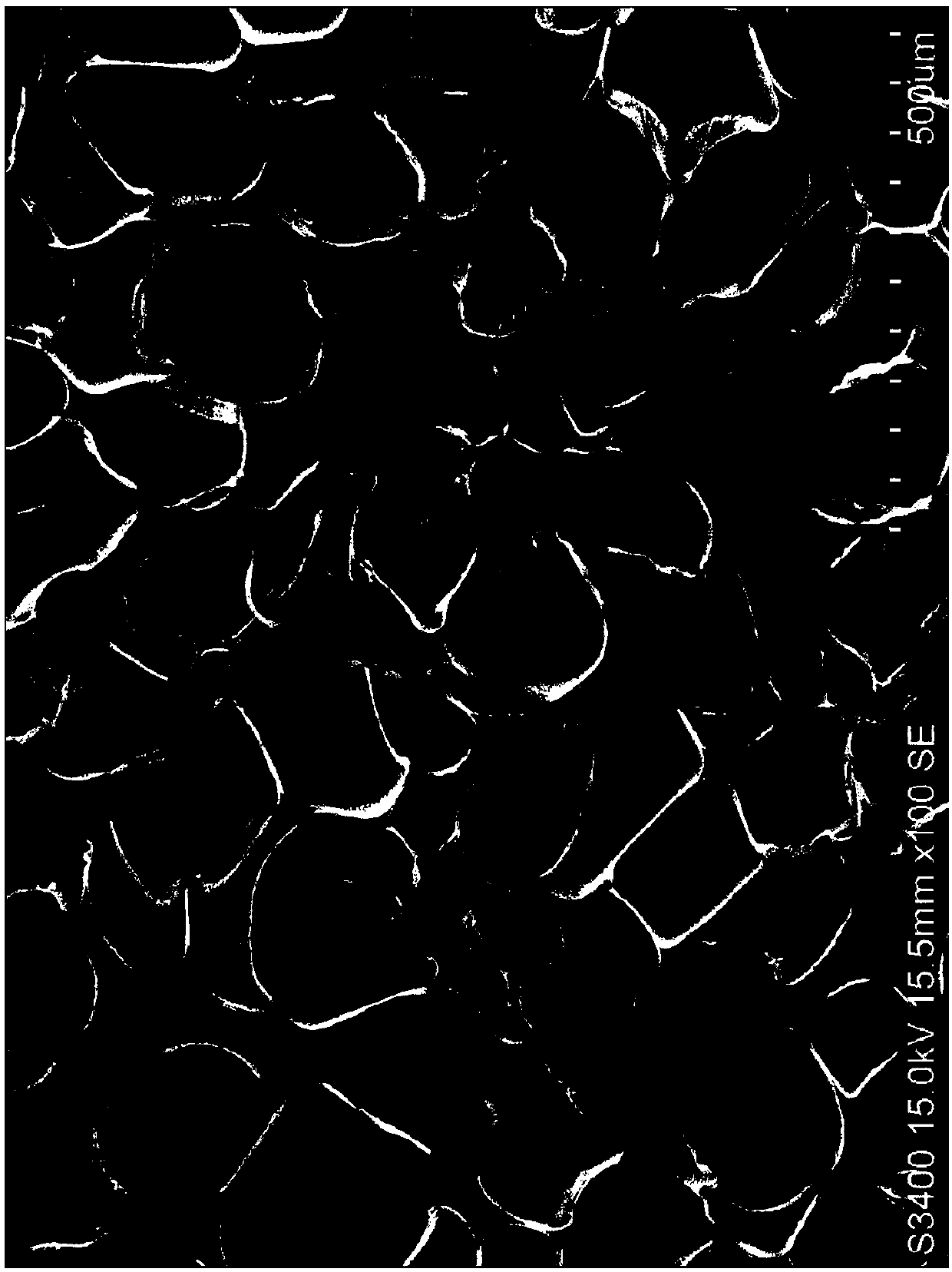

[0058] The specific formula includes: 60 parts of polyamide 6 is used as the polyamide skeleton material, and 30 parts of polyamide 11 is used as the polymer rebound material. Lattice layering, in order to utilize the penetration of foaming agent and the melt strength and crystallization rate control during foaming and expansion, so that polyamide with high crystallization and high melting point can be used as the skeleton support in the subsequent foaming material, with low crystallization and low melting point The high-quality polyamide is used as a pressure-resistant and resilient part in the subsequent foaming material. In addition, it also includes 0.5 part of nucleating agent (this embodiment adopts modified nano-calcium carbonate), foaming agent (this embodiment adopts CO 2 with N 2 Combination, volume ratio 1:1) 0.3 parts, auxiliary additives (this embodiment...

Embodiment 2

[0063] refer to figure 1 The shown process flow is used to prepare the following polyamide foam materials.

[0064] The specific formula includes: 97 parts of polyamide 6 are used as the polyamide skeleton material, and 1 part of polyamide 11 is used as the polymer rebound material. In addition, it also includes 0.05 part of nucleating agent (this embodiment uses modified nano-calcium carbonate), foaming agent (this embodiment uses CO 2 and N 2 , volume ratio 1:1) 0.1 part, auxiliary auxiliary agent (this embodiment includes antioxidant, flame retardant and filler) 0.5 part.

[0065] Subsequent process route is basically consistent with embodiment 1.

Embodiment 3

[0067] refer to figure 1 The shown process flow is used to prepare the following polyamide foam materials.

[0068] The specific formula includes: the polyamide skeleton material uses 1 part of polyamide 6, and the polymer rebound material uses 97 parts of polyamide 11. In addition, it also includes 0.01 part of nucleating agent (this embodiment uses modified nano-calcium carbonate), foaming agent (this embodiment uses CO 2 and N 2 , volume ratio 1:1) 1 part, auxiliary auxiliary agent (this embodiment includes antioxidant, flame retardant and filler) 20 parts.

[0069] Subsequent process route is basically consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com