Environment-friendly preparation method of plastic color master batch

A color masterbatch and environment-friendly technology, which is applied in the field of environment-friendly preparation of color masterbatch, can solve the problems of dispersion inhomogeneity, compatibility, chemical pollution, etc., and achieve the effects of improving production efficiency, large diffusivity coefficient and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

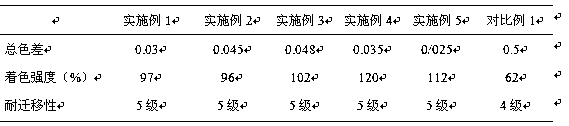

Examples

Embodiment 1

[0021] (1) Put 20g of iron oxide red into a 500ml autoclave, then add supercritical fluid carbon dioxide fluid into the autoclave, and adjust the pressure in the autoclave to 8MPa;

[0022] (2) Heating the autoclave in step (1), so that the substance capable of producing a supercritical state in step (1) becomes a supercritical fluid, the heating temperature is 50°C, and the pressure in the autoclave is 7.8 MPa;

[0023] (3) Use a magnetic stirrer to stir at high speed for 1 hour, dissolve the inorganic pigment in the supercritical fluid, and obtain an inorganic pigment-supercritical substance solution;

[0024] (4) Introduce 100g of porous carrier resin polypropylene into the autoclave equipped with inorganic pigment-supercritical substance solution in step (3), and after stirring with a magnetic stirrer for 20 hours, keep the temperature constant and reduce the pressure, and adjust the pressure at 0.1MPa, and stir for 1 hour, deflate through the vent valve, and take out the ...

Embodiment 2

[0027] (1) Put 15g of iron oxide red into a 500ml autoclave, then add supercritical fluid carbon dioxide fluid into the autoclave, and adjust the pressure in the autoclave to 8MPa.

[0028] (2) Heating the autoclave in step (1), so that the substance capable of producing a supercritical state in step (1) becomes a supercritical fluid, the heating temperature is 80°C, and the pressure in the autoclave is 10MPa;

[0029] (3) Use a magnetic stirrer to stir at high speed for 3 hours, dissolve the inorganic pigment in the supercritical fluid, and obtain an inorganic pigment-supercritical substance solution;

[0030] (4) Introduce 100g of porous carrier resin polyamide into the autoclave equipped with inorganic pigment-supercritical substance solution in step (3), and after stirring for 30 hours with a magnetic stirrer, keep the temperature constant and reduce the pressure, and adjust the pressure at 12MPa, and stir for 1 hour, deflate through the vent valve, and take out the coarse...

Embodiment 3

[0033] (1) Put 15g of iron oxide red into a 500ml autoclave, then add supercritical fluid carbon dioxide fluid into the autoclave, and adjust the pressure in the autoclave to 8MPa.

[0034] (2) Heating the autoclave in step (1), so that the substance capable of producing a supercritical state in step (1) becomes a supercritical fluid, the heating temperature is 100°C, and the pressure in the autoclave is 16MPa;

[0035] (3) Use a magnetic stirrer to stir at high speed for 1 hour, dissolve the inorganic pigment in the supercritical fluid, and obtain an inorganic pigment-supercritical substance solution;

[0036] (4) Introduce 100g of porous carrier resin polystyrene into the autoclave equipped with inorganic pigment-supercritical substance solution in step (3), and after stirring for 20 hours with a magnetic stirrer, keep the temperature constant and reduce the pressure to adjust the pressure Stir at 1MPa for 1 hour, deflate through the vent valve, and take out the coarse color...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com