A kind of electroactive anticorrosion coating based on γ-polyglutamic acid and its preparation method

An anti-corrosion coating, polyglutamic acid technology, applied in coatings, electrolytic coatings, etc., can solve the problems of non-degradable conductive polymers, application limitations, tissue inflammation, etc., to maintain biocompatibility and biodegradability , The preparation method is simple, and the effect of increasing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of electroactive γ-PGA: Weigh 1 mmol γ-PGA and dissolve it in 10 mL dimethyl sulfoxide (DMSO), heat to 70°C and stir to dissolve. After forming a uniform solution, add 1 mmol HOBt and 1 mmol EDC·HCl to activate Carboxyl group, then add 0.2mmol electroactive small molecule aniline tetramer (TANi), react at 50°C for 24h, and then precipitate and centrifuge in ethanol to obtain electroactive γ-PGA-TANi with a modification rate of 10%.

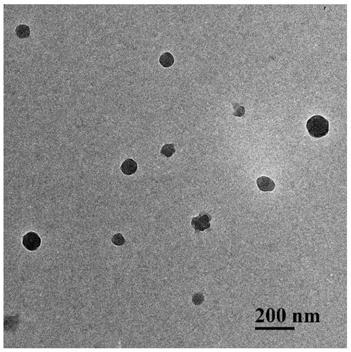

[0023] (2) Preparation of electroactive self-assembled colloidal particle solution: the γ-PGA-TANi prepared in step (1) was dissolved in DMSO to prepare a solution with a concentration of 5 mg / mL, and the alcohol solution was added dropwise under stirring, A stable solution of electroactive colloidal particles is prepared by a selective solvent method. The particles are spherical, with a diameter of 70nm and a charge of -35mV. The morphology and size of the colloidal particles in the dry state are shown in the attached figu...

Embodiment 2

[0026] (1) Preparation of electroactive γ-PGA: Weigh 1 mmol γ-PGA and dissolve it in 10 mL dimethyl sulfoxide (DMSO), heat to 70°C and stir to dissolve. After forming a uniform solution, add 1 mmol HOBt and 1 mmol EDC·HCl to activate Carboxyl group, then add 0.5mmol electroactive small molecule aniline tetramer (TANi), react at 50°C for 24h, and then precipitate and centrifuge in ethanol to obtain electroactive γ-PGA-TANi with a modification rate of 20%.

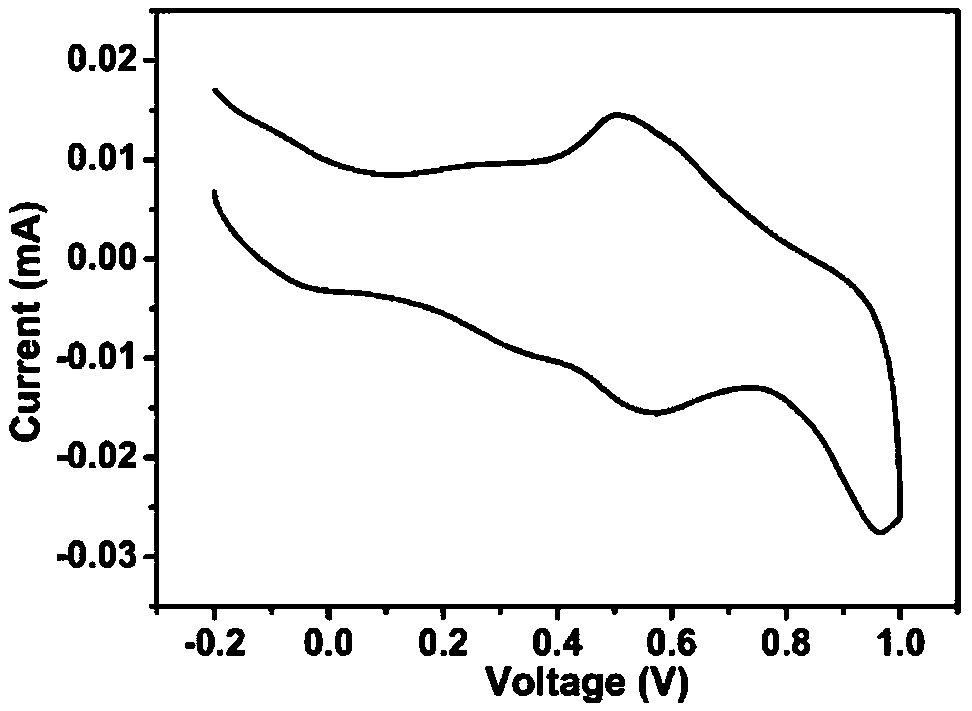

[0027] (2) Preparation of electroactive self-assembled colloidal particle solution: the γ-PGA-TANi prepared in step (1) was dissolved in DMSO to prepare a solution with a concentration of 8 mg / mL, and the alcohol solution was added dropwise under stirring, A stable solution of electroactive colloidal particles is prepared by a selective solvent method. The particles are spherical, with a diameter of 100nm and a charge of -32mV. The CV curve of colloidal particles is attached figure 2 shown.

[0028] (3) Preparation of ele...

Embodiment 3

[0030] (1) Preparation of electroactive γ-PGA: Weigh 1 mmol γ-PGA and dissolve it in 10 mL dimethyl sulfoxide (DMSO), heat to 70°C and stir to dissolve. After forming a uniform solution, add 1 mmol HOBt and 1 mmol EDC·HCl to activate Carboxyl group, then add 1 mmol of electroactive small molecule aniline tetramer (TANi), react at 50°C for 24h, and then precipitate and centrifuge in ethanol to obtain electroactive γ-PGA-TANi with a modification rate of 27%.

[0031] (2) Preparation of electroactive self-assembled colloidal particle solution: the γ-PGA-TANi prepared in step (1) was dissolved in DMSO to prepare a solution with a concentration of 10 mg / mL, and the alcohol solution was added dropwise under stirring, A stable solution of electroactive colloidal particles is prepared by a selective solvent method. The particles are spherical in shape with a diameter of 120nm and a charge of -28mV.

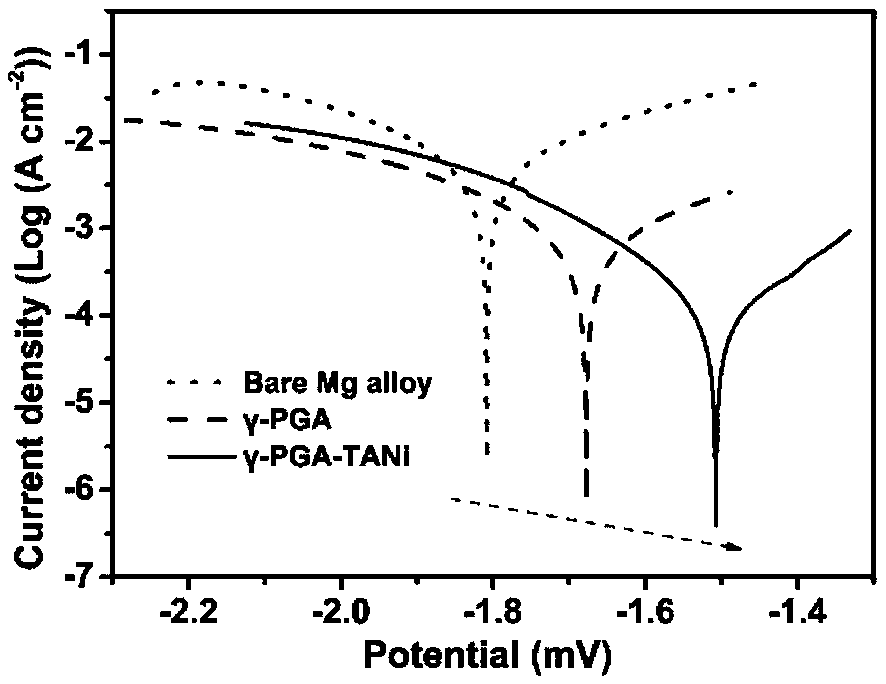

[0032](3) Preparation of electroactive anticorrosion coating on the surface of magnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com