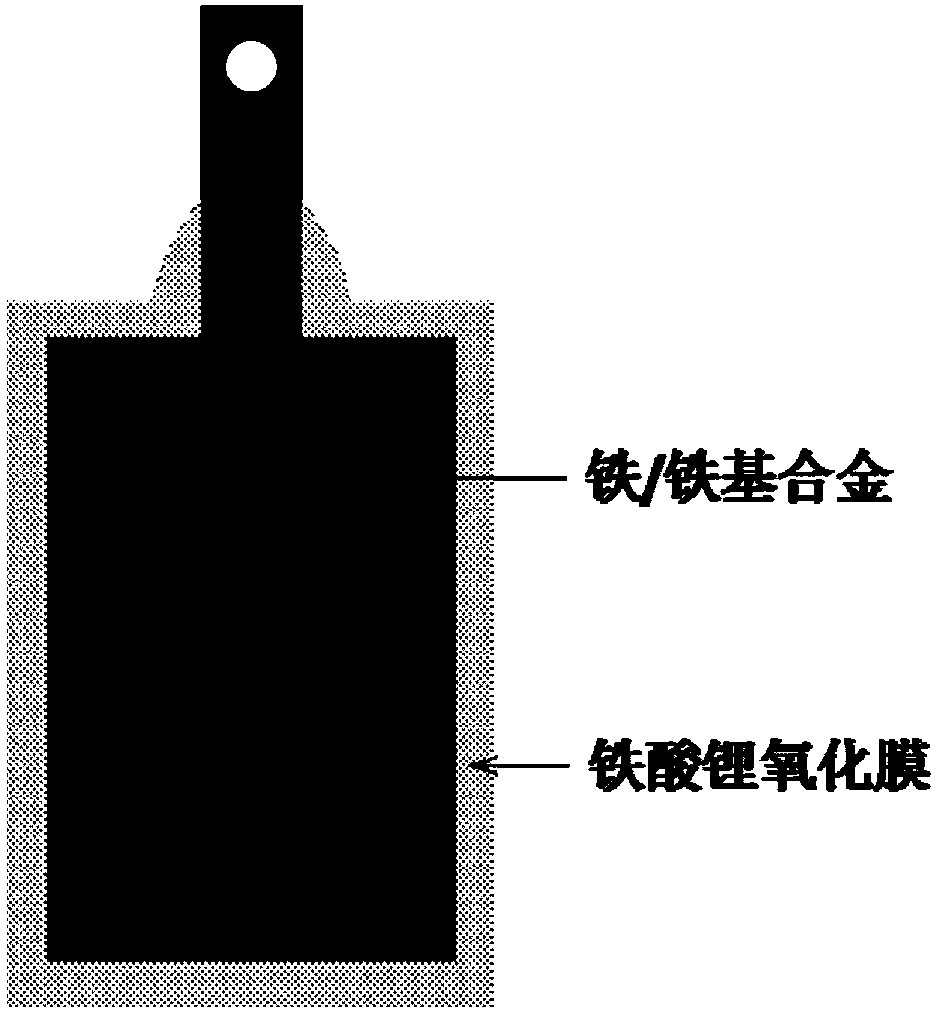

Iron-based inert anode with lithium ferrite protective film and preparation method and application of iron-based inert anode

An inert anode, lithium ferrite technology, applied in the field of electrochemistry, can solve the problems of contaminated cathode products, strong anodic oxidation, anode damage, etc., and achieve the effects of low price, simple preparation method and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of inert anode: at 650℃, with Li 2 CO 3 -Na 2 CO 3 -K 2 CO 3 (Mole ratio Li 2 CO 3 :Na 2 CO 3 :K 2 CO 3 =43.5:31.5:25) Molten salt is used as the electrolyte, and the pure iron electrode is at 100mA / cm 2 The constant current anode pre-oxidation is carried out at a current density of 10 min to prepare an iron-based inert anode with a lithium ferrite protective film.

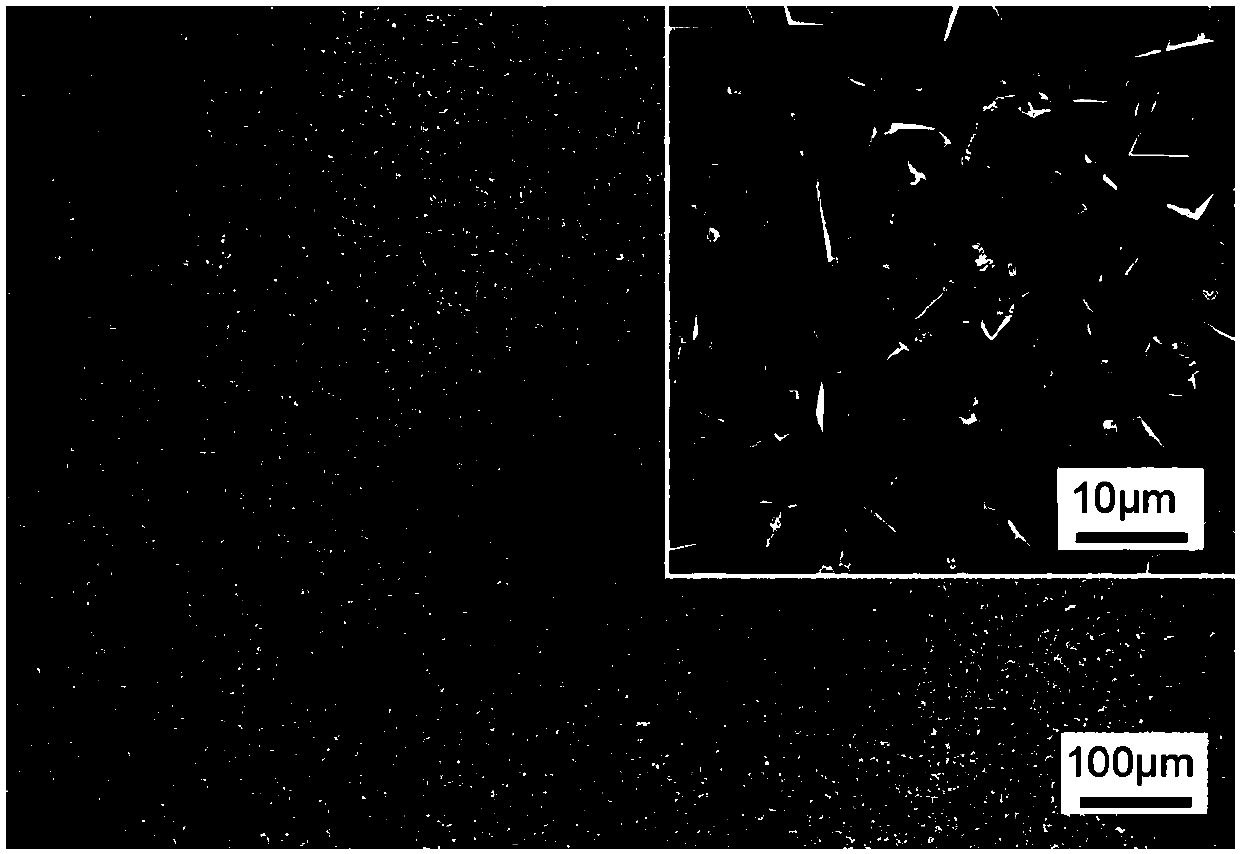

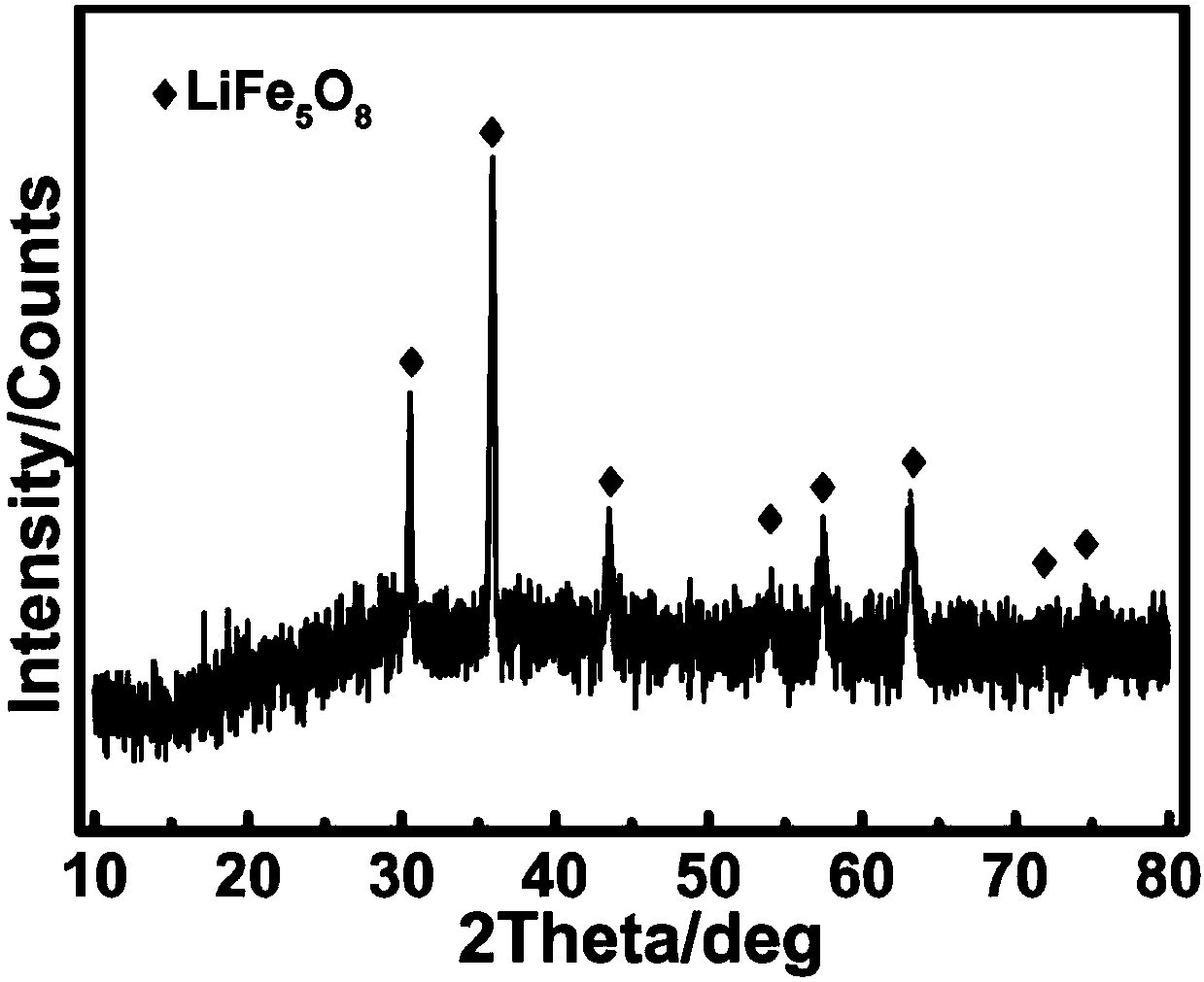

[0026] The prepared iron-based inert anodes were tested by SEM and XRD, and the results were as follows: Figure 2-3 Shown. The SEM image shows that the pure iron electrode is covered by a dense octahedral structure oxide crystal ( figure 2 ), XRD analysis test shows that the composition of the surface oxide film is LiFe 5 O 8 ( image 3 ). This proves that the dense LiFe is prepared under the above conditions 5 O 8 Pure iron inert anode with protective film.

[0027] High temperature molten salt electrolysis experiment: at 450℃, with Li 2 CO 3 -Na 2 CO 3 -K 2 CO 3 (Mole ratio Li 2 CO 3 :Na 2 CO 3 ...

Embodiment 2

[0029] Preparation of inert anode: at 700℃, with Li 2 CO 3 -K 2 CO 3 (Mole ratio Li 2 CO 3 :K 2 CO 3 =62:38) Molten salt is used as electrolyte, nickel sheet is used as cathode, and Q235 carbon steel electrode is anodized at constant cell voltage at 2.2V cell voltage for 2h. Under these conditions, dense LiFeO is prepared. 2 Carbon steel inert anode with protective film.

[0030] High temperature molten salt electrolysis experiment: at 450℃, with Li 2 CO 3 -Na 2 CO 3 -K 2 CO 3 (Mole ratio Li 2 CO 3 :Na 2 CO 3 :K 2 CO 3 =43.5:31.5:25) Molten salt is used as electrolyte and nickel sheet is used as cathode to prepare dense LiFeO 2 The carbon steel electrode with protective film is used as inert anode. At 200mA / cm 2 Constant current electrolysis is carried out at the current density of the anode, and carbon dioxide gas is continuously introduced during the electrolysis process to obtain carbon material at the cathode and oxygen at the anode. During the electrolysis for 200 hours, the ...

Embodiment 3

[0032] Preparation of inert anode: at 750℃, with Li 2 CO 3 Molten salt is used as the electrolyte, and the 310S stainless steel electrode is at 0.7V (relative to Ag / Ag + ) Potential anode pre-oxidation for 20 minutes. Under these conditions, dense LiFeO was prepared 2 Stainless steel inert anode with protective film.

[0033] High temperature molten salt electrolysis experiment: at 650℃, with Li 2 CO 3 -Na 2 CO 3 -K 2 CO 3 (Mole ratio Li 2 CO 3 :Na 2 CO 3 :K 2 CO 3 =43.5:31.5:25) Molten salt is used as electrolyte, and iron oxide sheet is used as cathode to prepare dense LiFeO 2 The stainless steel electrode of the protective film is used as the anode. At 250mA / cm 2 Constant current electrolysis is carried out at a current density of the anode to obtain elemental iron at the cathode and oxygen at the anode. During the 20h electrolysis process, the inert anode has strong oxygen evolution capability and can remain stable for a long time. The dense LiFeO prepared in this example 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com