SEBS/biochar compound modified asphalt and preparation method thereof

A technology of compound modified asphalt and modified asphalt, applied in building structures, building components, building thermal insulation materials, etc., can solve the problems of reducing the low-temperature cracking resistance of asphalt and the influence of the comprehensive performance of asphalt, so as to improve the low-temperature cracking resistance. , good low temperature crack resistance and high temperature stability, and the effect of improving high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

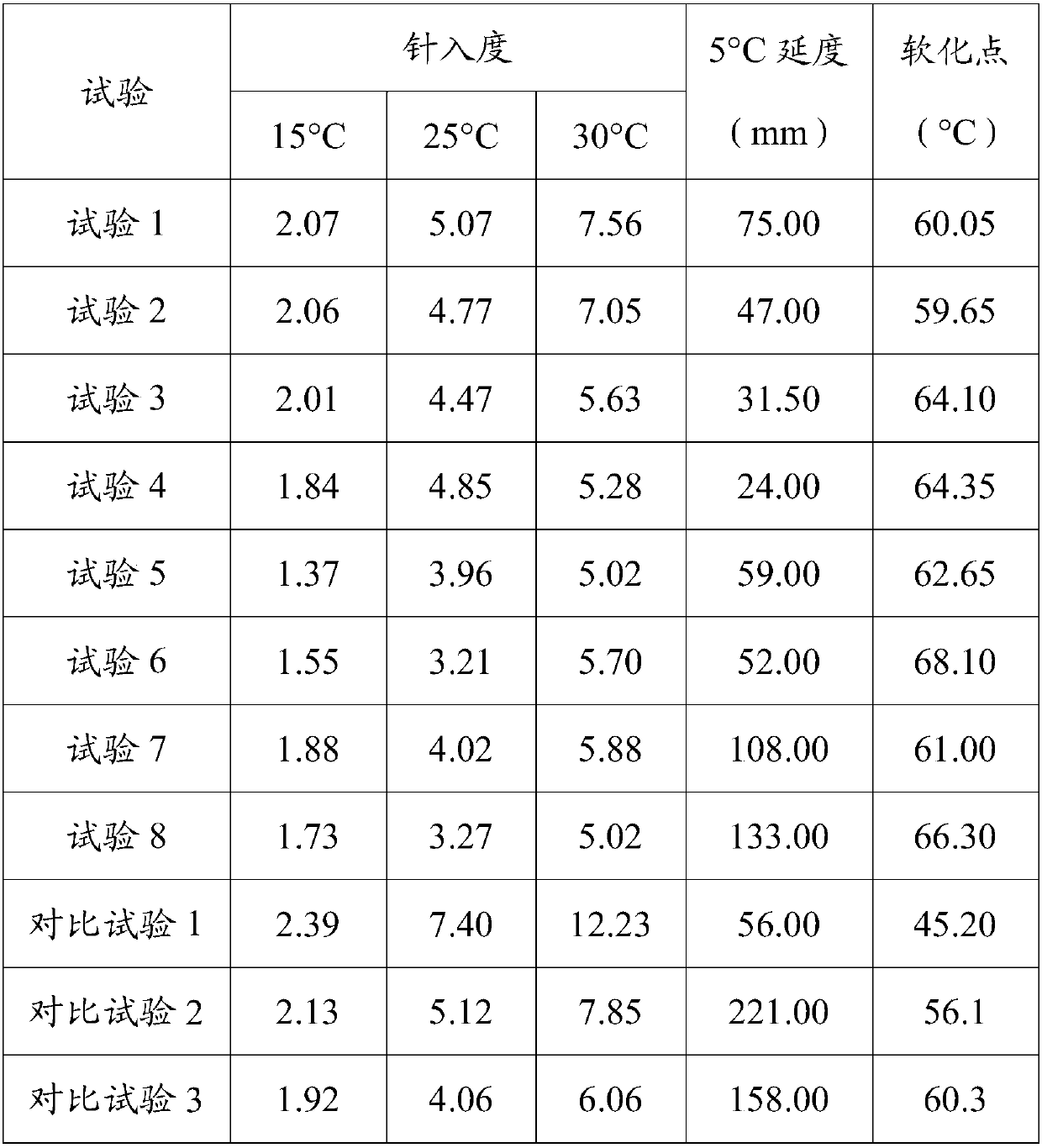

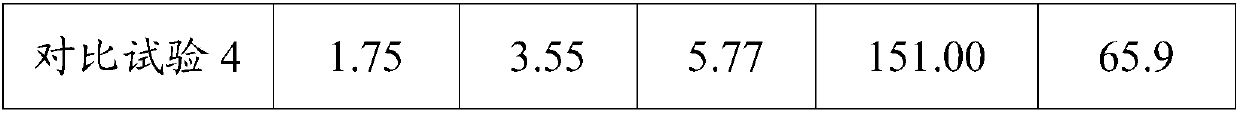

Examples

Embodiment 1

[0031] A SEBS / biochar composite modified asphalt, including the following raw materials: 500g of SK90 base asphalt, YH-503SEBS accounting for 5% of the mass of SK90 base asphalt and DS-510F biochar accounting for 4% of the mass of SK90 base asphalt.

[0032] The preparation method of above-mentioned SEBS / biochar composite modified asphalt comprises the following preparation steps:

[0033] Step 1, heat the base asphalt in an oven at 160°C for 60 minutes to a molten state, add YH-503SEBS to the heated base asphalt, stir at 165°C for 12.5 minutes, and heat at a shear temperature of 170°C and a shear rate of 5000r Cut for 30 minutes under the condition of 1 / min, and then swell and develop in an oven at 170°C for 1 hour to obtain modified asphalt, which is ready for use;

[0034] Step 2: Dry the biochar in an oven at 120°C for 2 hours, put it in a drying container and cool it to room temperature, and obtain the cooled biochar for later use;

[0035] Step 3: Add the cooled biochar...

Embodiment 2

[0037] A SEBS / biochar composite modified asphalt, including the following raw materials: 500g of SK90 base asphalt, YH-503SEBS accounting for 5% of the mass of SK90 base asphalt and DS-510F biochar accounting for 8% of the mass of SK90 base asphalt.

[0038] The preparation method of above-mentioned SEBS / biochar composite modified asphalt comprises the following preparation steps:

[0039] Step 1, heat the base asphalt in an oven at 160°C for 60 minutes to a molten state, add YH-503SEBS to the heated base asphalt, stir at 165°C for 12.5 minutes, and heat at a shear temperature of 170°C and a shear rate of 5000r Cut for 30 minutes under the condition of 1 / min, and then swell and develop in an oven at 170°C for 1 hour to obtain modified asphalt, which is ready for use;

[0040] Step 2: Dry the biochar in an oven at 120°C for 2 hours, put it in a drying container and cool it to room temperature, and obtain the cooled biochar for later use;

[0041] Step 3: add the cooled biochar...

Embodiment 3

[0043] A SEBS / biochar composite modified asphalt, including the following raw materials: 500g of SK90 base asphalt, YH-503SEBS accounting for 5% of the mass of SK90 base asphalt and DS-510F biochar accounting for 12% of the mass of SK90 base asphalt.

[0044] The preparation method of above-mentioned SEBS / biochar composite modified asphalt comprises the following preparation steps:

[0045] Step 1: Heat the base asphalt in an oven at 160°C for 60 minutes to a molten state, add YH-503SEBS to the heated base asphalt, stir at 165°C for 12.5 minutes, and when the shear temperature is 170°C and the shear rate is Cut at 5000r / min for 30min, and then swell and develop in an oven at 170°C for 1h to obtain modified asphalt for later use;

[0046] Step 2: Dry the biochar in an oven at 120°C for 2 hours, put it in a drying container and cool it to room temperature, and obtain the cooled biochar for later use;

[0047] Step 3: Add the cooled biochar into the modified asphalt in 6 times w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| 300% modulus stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com