Method for manufacturing low-dust high-insulation aerogel blanket

An airgel felt and gel technology, which is applied in the field of airgel felt preparation, can solve the problems of improving thermal conductivity, etc., and achieve the effects of improving adhesion, improving thermal conductivity, and reducing dust generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention provides a kind of preparation method of airgel felt, comprising:

[0037] a) preparation of substrates for mats surface-treated with an acid solution;

[0038] b) preparing a silica sol comprising a water glass solution;

[0039] c) impregnating said surface-treated substrate for felt with said silica sol;

[0040] d) gelling the silica sol in a state where the base material for felt is impregnated with the silica sol; and

[0041] e) Perform surface modification and drying.

[0042] Hereinafter, each step of the preparation method of the airgel mat of the present invention will be described in detail.

[0043] Step a)

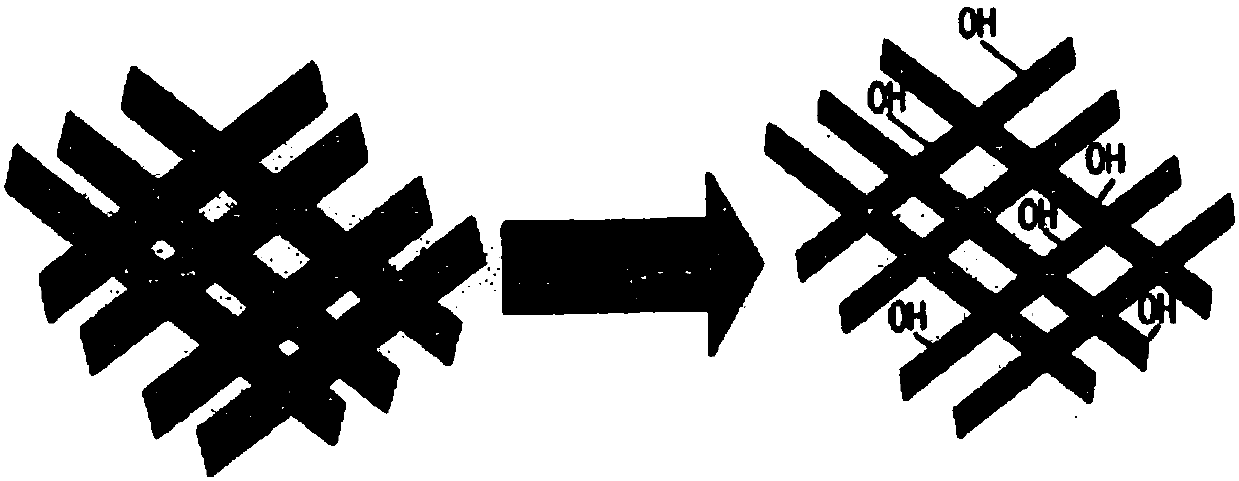

[0044] Step a) according to one embodiment of the present invention is a step of improving the adhesion performance of the silica airgel by increasing the roughness and porosity of the surface of the substrate used for the felt in the airgel felt, wherein, Substrates for felting are pretreated with an acid solution.

[004...

Embodiment 1 to 3

[0103] With acetic acid (CH 3 COOH) treated glass mat to prepare a silica sol containing 5.2% by weight of water glass solution. The glass mat surface-treated with acetic acid was impregnated with silica sol, and treated with acetic acid as an acid catalyst to induce gelation. Thereafter, after aging at 80° C. for 20 minutes to 30 minutes, solvent replacement with methanol was performed 3 to 4 times at 50° C. Subsequently, surface modification was carried out with 70 v / v % methanol and 30 v / v % HMDS at 50 °C for 5 hours to 6 hours, the mixture was washed three times with hexane over 2 hours to 3 hours to remove by-products, and then Dry at 150°C for 1 hour to prepare an airgel mat.

Embodiment 4 to 6

[0105] An airgel mat was prepared in the same manner as in Examples 1 to 3, except that the glass mat was treated with hydrochloric acid (HCl) instead of acetic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com