Preparation method of codoping electrode nitrogen with porous carbon/ferriferrous oxide composite material for super capacitor, and application thereof

A technology for supercapacitors and ferroferric oxide, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors. It can solve the problems of low tap density, low energy density and high cost of supercapacitors, and achieve good specific capacitance. , excellent electrical properties, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

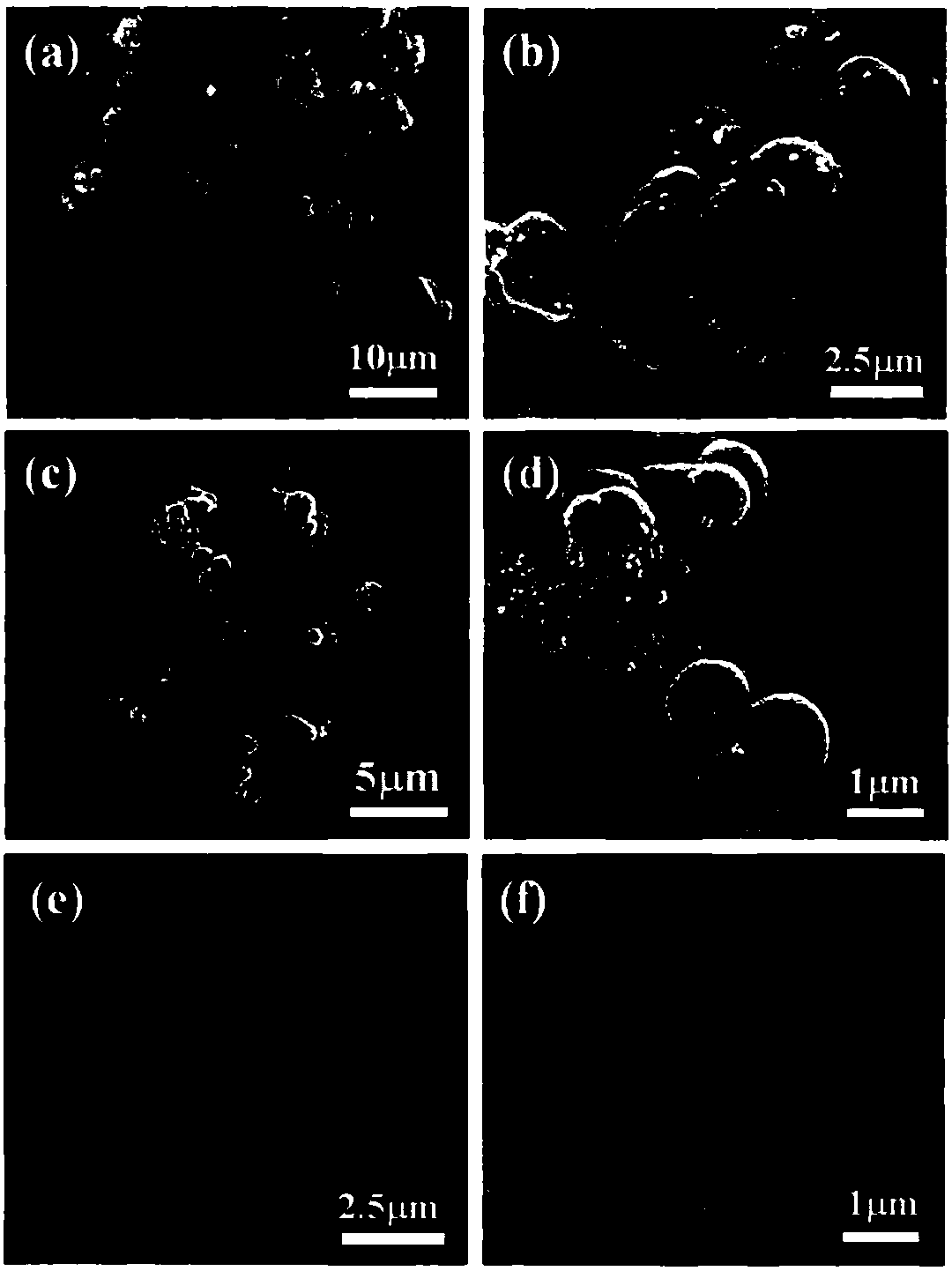

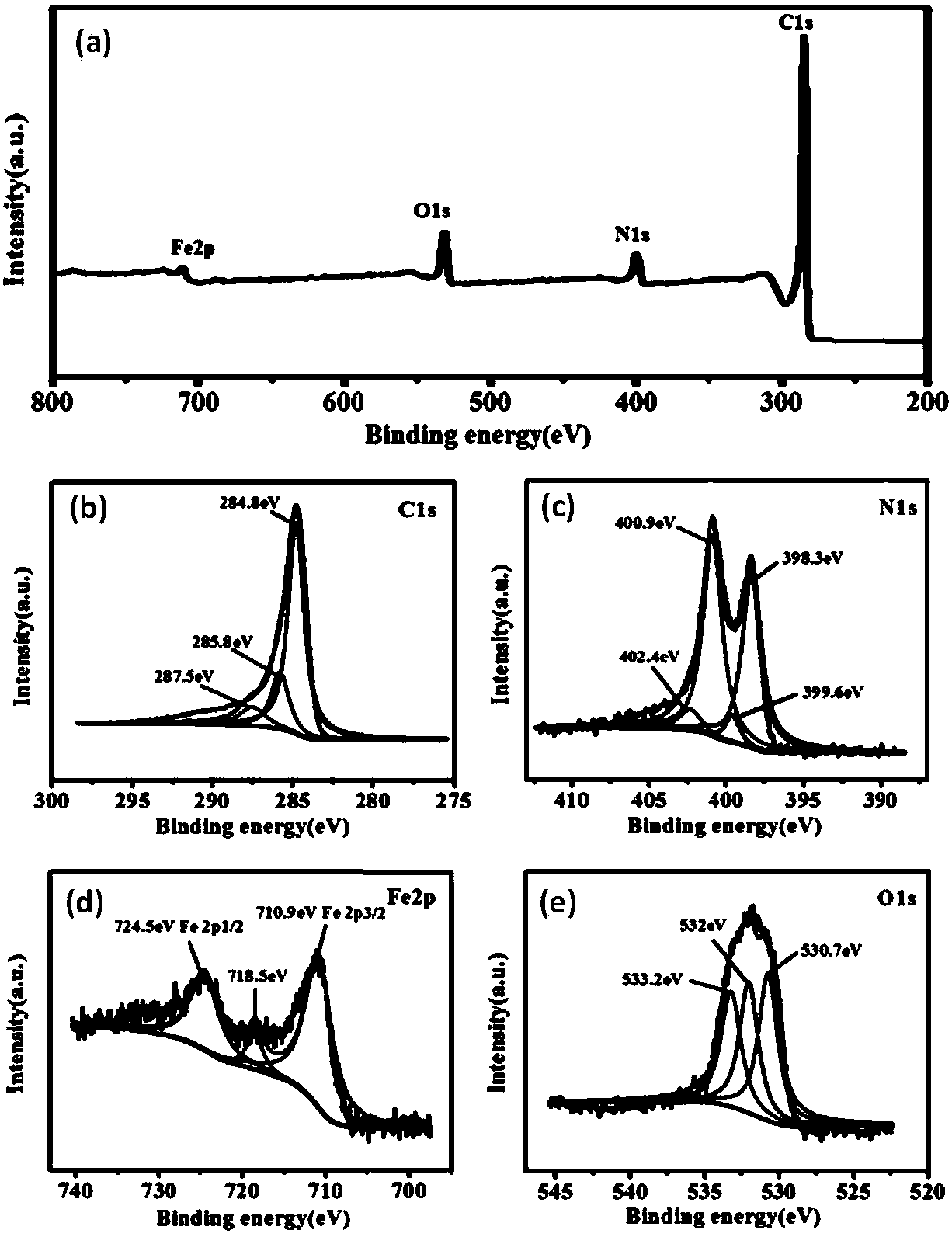

[0038] (1) Weigh 10mmol of cyclopentadienyl iron and 5mg of iron powder into a 50mL polytetrafluoroethylene reactor liner, then add 2mL of hexachlorobutadiene as the iron source and carbon source, mix, and add 28mL Pyridine is used as a solvent, sealed and put into a stainless steel high-temperature reactor, screwed on the lid of the reactor, and placed in an oven at 200°C for 6 hours;

[0039] (2) After the reaction is over, let it cool to room temperature naturally, turn off the power of the oven, turn on the reaction kettle, transfer all the products in the kettle to a glass watch glass, and place it in an oven at 120°C for 6 hours;

[0040] (3) Collect the dried sample in a reagent bottle, weigh 1g of the above-prepared sample into the inner tank of the polytetrafluoroethylene reactor, add 25mL of saturated urea solution, seal it, and put it into the stainless steel high-temperature reactor. Cover the reaction kettle, place it in an oven at 200°C for 12 hours, naturally cool to...

Embodiment 2-3

[0043] Same as in Example 1, except that the cyclopentadienyl iron (Fe(C 5 H 5 ) 2 The amount of) is replaced with 5mmol, 15mmol, and the amount of iron powder is replaced with 2.5mg, 7.5mg, other operations are the same, the label of the obtained material is 5-Fe-N-C urea -400, 15-Fe-N-C urea -400;

Embodiment 4-5

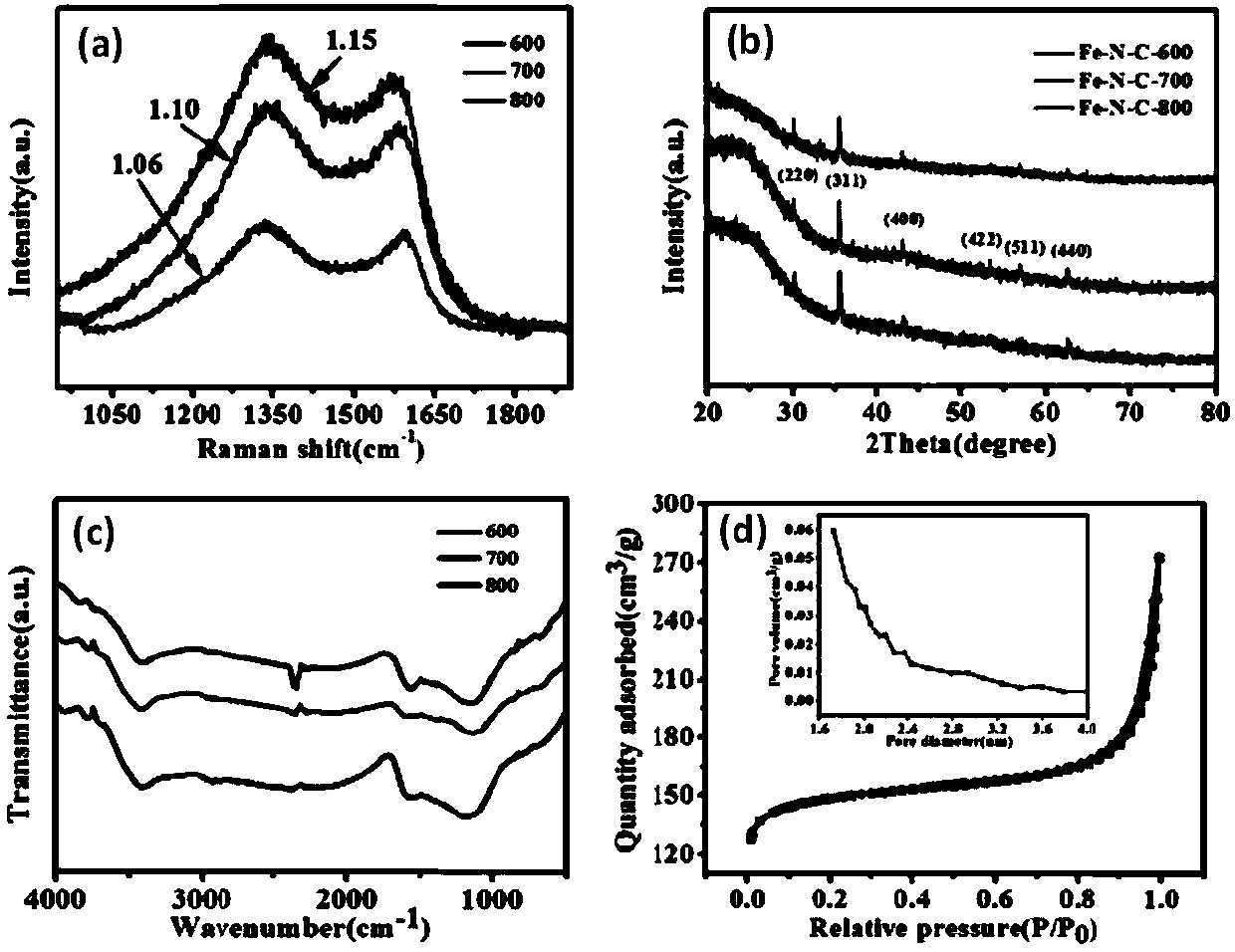

[0045] The same as the steps in Example 1, except that the temperature of the tube furnace in step (4) in Example 1 was increased to 600°C and 800°C, the other operations were unchanged, so that the marking of the material was 10-Fe- NC urea -600, 10-Fe-N-C urea -800;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com