Motorcycle water cooling engine

A technology for water-cooled engines and motorcycles, which is applied to engine components, engine lubrication, machines/engines, etc. It can solve problems such as insufficient pump oil, jamming, and mixed lubricating oil, so as to improve the water cooling effect and lubrication effect. The effect of large channel volume and increased pump oil volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

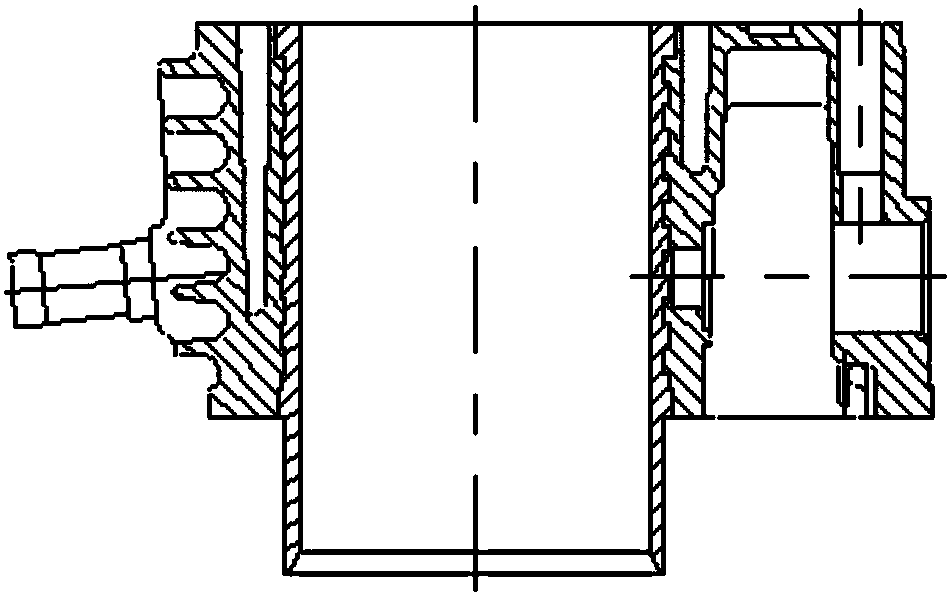

[0049] see Figure 6 , the motorcycle water-cooled engine of the present invention comprises a crankcase assembly 10, a crankcase cover assembly 20, a cylinder block 30, a cylinder head 40 and a cylinder head cover 50, the upper end of the cylinder block 30 is connected with the lower end of the cylinder head 40 and is sealed by a cylinder gasket 60, Cylinder head gasket structure see Figure 21 . The present invention improves the cylinder block 30, the cylinder head 40, the crankcase assembly 10, the oil pump, the cylinder gasket 60 and the oil filter 70 respectively. Detailed introduction will be made below in conjunction with the accompanying drawings.

[0050] Cylinder block improvements:

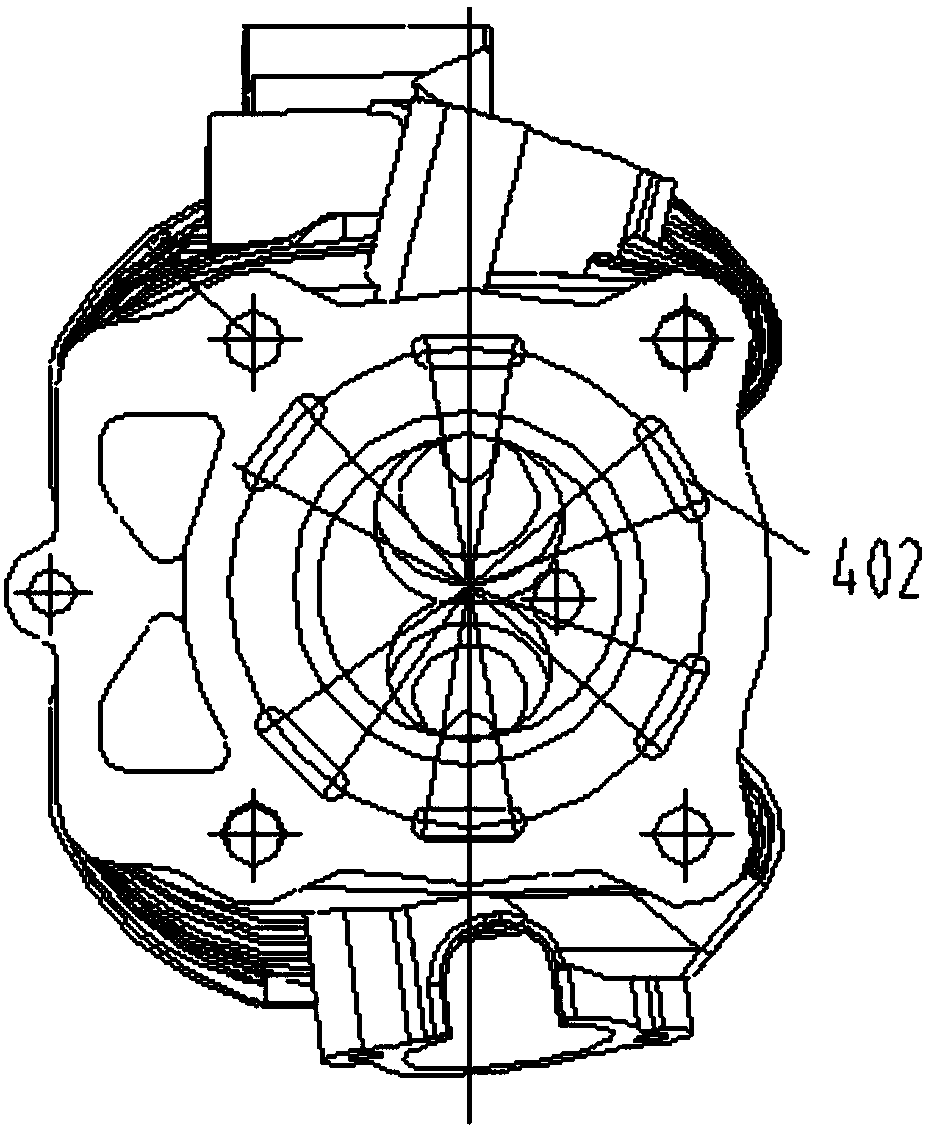

[0051] see Figure 7-Figure 9 , as can be seen from the figure, the present invention is provided with an annular closed cylinder waterway 302 around the cylinder hole 309 inside the cylinder block 30, a water inlet 303 is provided on the side of the cylinder block 30, and a water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com