Active oil-gas separator

An oil and gas separator, active technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of low oil and gas separation efficiency, deteriorating environment, poor engine emissions, etc., to increase the separation burden, improve efficiency, avoid Effect of reduction in separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

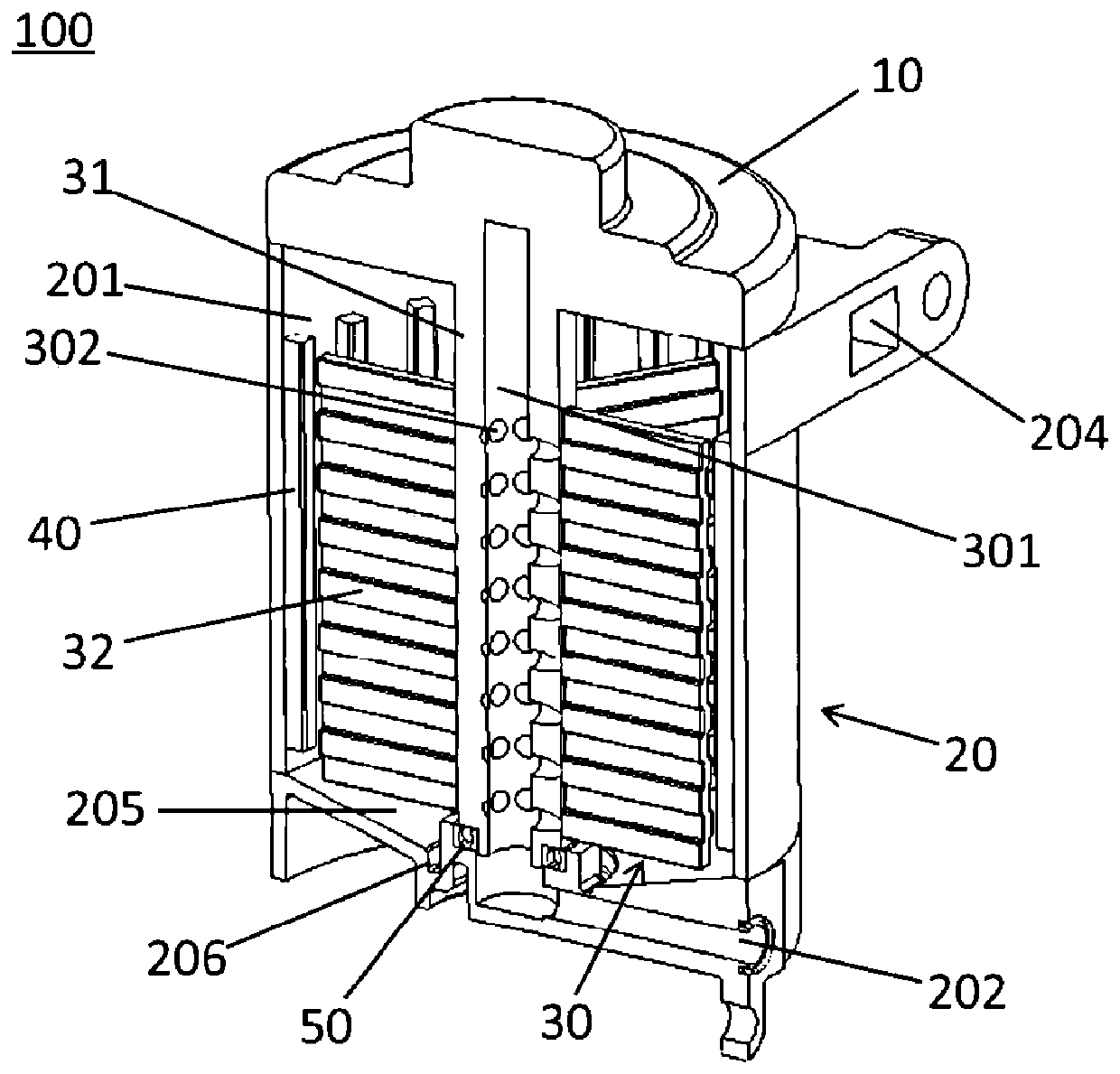

[0035] figure 1 is a schematic structural diagram of an oil-gas separator 100 according to an embodiment of the present invention. figure 2 is a cross-sectional view of an oil-gas separator 100 according to an embodiment of the present invention. Such as figure 1 As shown, the present invention provides an active oil-air separator 100 for separating the exhaust gas of the engine crankcase, and the oil-air separator 100 may generally include a motor 10, a body 20 and a rotating device 30 (see figure 2 ). The motor 10 is used to provide rotational power. Such as figure 2 As shown, the inside of the body 20 is provided with a first cavity 201, and is provided with an oil and gas inlet 202 and an oil return port 203 at the bottom of the body 20 and an air outlet 204 at the top of the body 20. One end of the oil and gas inlet 202 is connected to the engine crankcase The oil return port 203 is used to communicate with the first chamber 201 and the crankcase of the engine, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com