Super-hydrophobic flame retardant fabric with function of separating oil from water and preparation method thereof

A technology of oil-water separation and flame-retardant fabrics, which is applied in the direction of flame-retardant fibers, immiscible liquid separation, plant fibers, etc., can solve the problems of inability to achieve super-hydrophobicity after modification, failure of fabric surface coating, poor durability, etc., to achieve Not easy to wear, improve flame retardancy, improve thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

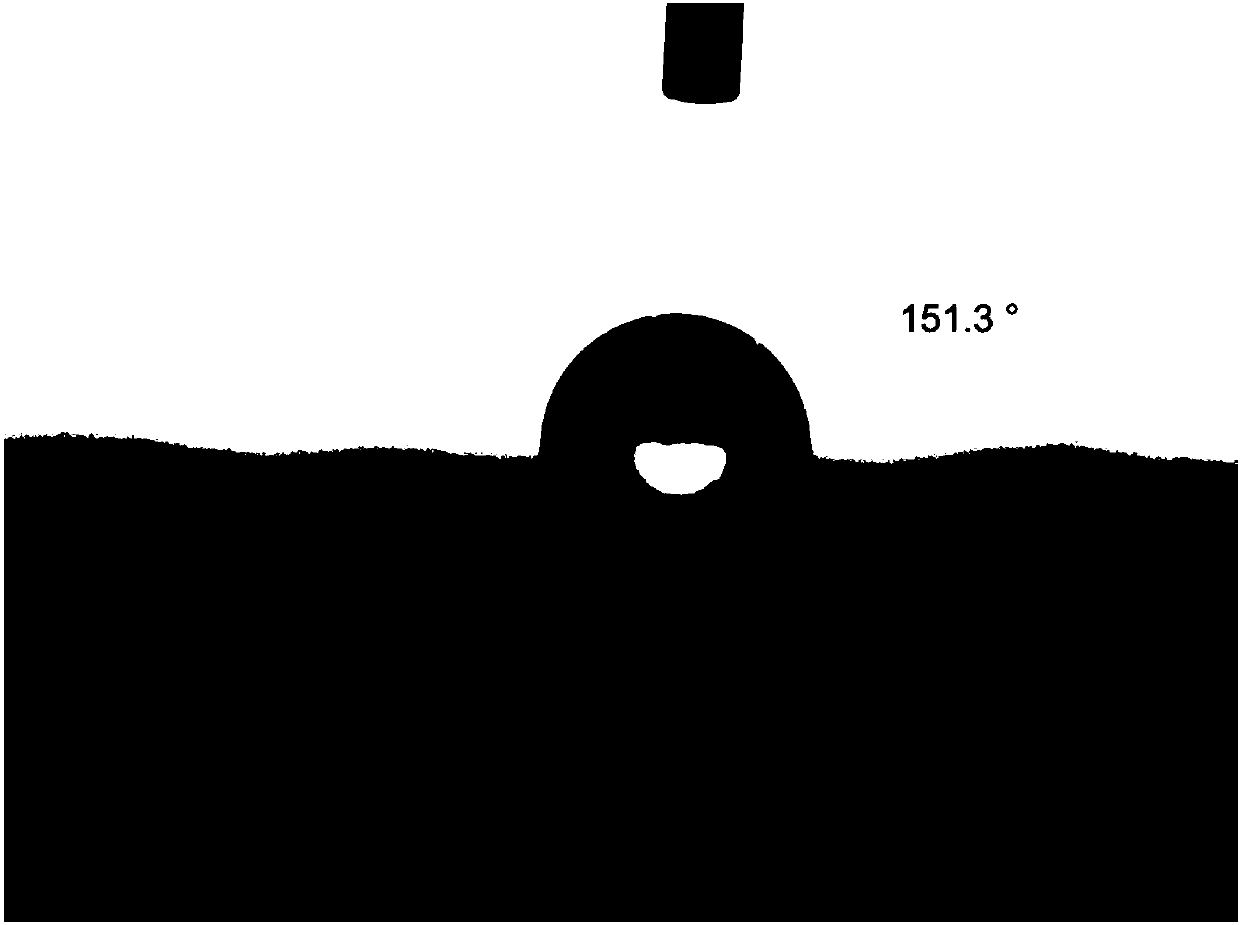

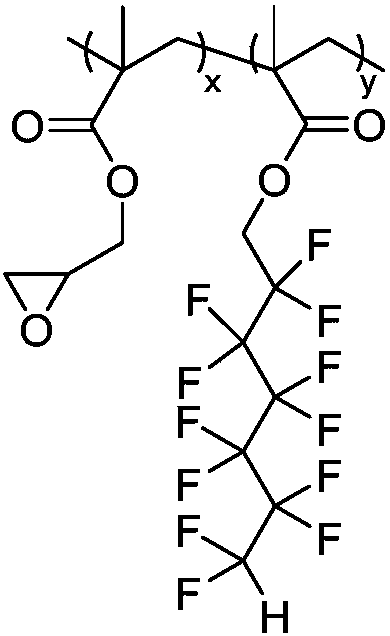

Embodiment 1

[0035] (1) Into the reaction vessel were sequentially added 1.42g (10mmol) glycidyl methacrylate, 6g (15mmol) dodecafluoroheptyl methacrylate, 0.0082g (0.05mmol) azobisisobutyronitrile and 25mL tetrahydrofuran, Freeze and thaw three times with liquid nitrogen, fill it with argon, and react at 65℃ for 24h. After the reaction, it is precipitated with methanol and filtered. The filter cake is washed with methanol 3 to 4 times. The solid obtained is placed in a vacuum drying oven at 50℃. Dry for 24 hours to obtain P(GM-co-DM), where x:y=4:6, and its molecular weight is 34089.

[0036] (2) Add 1g (1.28mmol) P(GM-co-DM), 0.159g (0.64mmol) 1,3-bis(3-aminopropyl)-1,1,3,3-tetra After the compound is completely dissolved with methyldisiloxane and 50 mL of tetrahydrofuran, a 5*10 cm pure cotton fabric is immersed in the solution and reacted at 50° C. for 4 hours. The fabric is then taken out and placed in a fume hood, and after the solvent is evaporated and dried, it is put into an oven fo...

Embodiment 2

[0040] (1) Into the reaction vessel were sequentially added 1.42g (10mmol) glycidyl methacrylate, 6g (15mmol) dodecafluoroheptyl methacrylate, 0.0082g (0.05mmol) azobisisobutyronitrile and 25mL tetrahydrofuran, Freeze and thaw three times with liquid nitrogen, fill it with argon, and react at 65℃ for 24h. After the reaction, it is precipitated with methanol and filtered. The filter cake is washed with methanol 3 to 4 times. The solid obtained is placed in a vacuum drying oven at 50℃. Dry for 24 hours to obtain P(GM-co-DM), where x:y=4:6, and its molecular weight is 34089.

[0041] (2) Add 1g (1.28mmol) P(GM-co-DM), 0.56g (0.64mmol) aminopropyl isobutyl silsesquioxane and 50mL tetrahydrofuran into the reaction vessel. After the compound is completely dissolved, add a piece of 5*10cm pure cotton fabric is immersed in the solution and reacted at 50℃ for 4h. The fabric is then taken out and placed in a fume hood, and after the solvent is evaporated and dried, it is put into an oven ...

Embodiment 3

[0043] (1) Into the reaction vessel were sequentially added 1.42g (10mmol) glycidyl methacrylate, 6g (15mmol) dodecafluoroheptyl methacrylate, 0.0082g (0.05mmol) azobisisobutyronitrile and 25mL tetrahydrofuran, Freeze and thaw three times with liquid nitrogen, fill it with argon, and react at 65℃ for 24h. After the reaction, it is precipitated with methanol and filtered. The filter cake is washed with methanol 3 to 4 times. The solid obtained is placed in a vacuum drying oven at 50℃. Dry for 24 hours to obtain P(GM-co-DM), where x:y=4:6, and its molecular weight is 34089.

[0044] (2) Add 1g (1.28mmol) P(GM-co-DM), 0.01g (0.01mmol) octaaminophenyl oligomeric silsesquioxane and 50mL tetrahydrofuran into the reaction vessel. After the compound is completely dissolved, add A piece of 5*10cm pure cotton fabric is immersed in the solution and reacted at 50°C for 4h. Afterwards, the fabric is taken out and placed in a fume hood, and after the solvent is evaporated and dried, it is put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com