Safe, healthy and environmentally-friendly conductive ink and preparation method thereof

A conductive ink, a healthy technology, applied in ink, household utensils, applications, etc., can solve the problems of conductive ink containing toxic components, high cost, and application of teaching aids, achieve good conductive effect, low production cost, and reduce environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

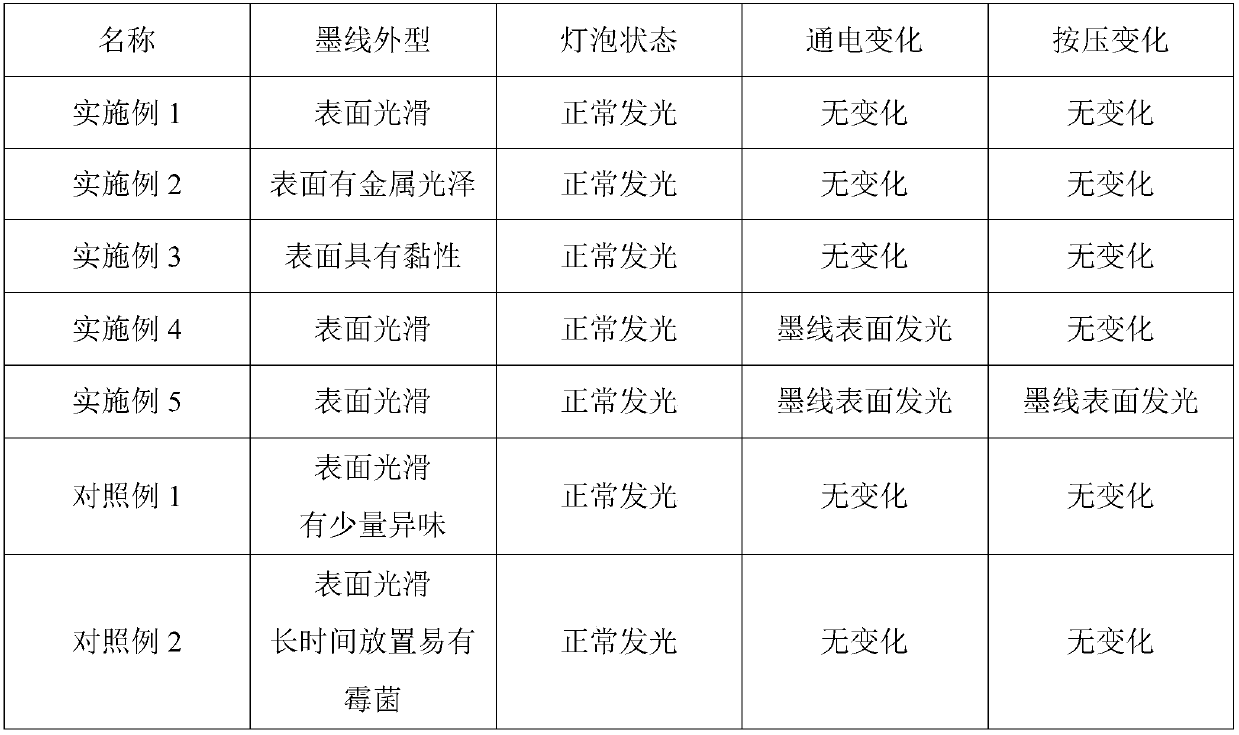

Examples

Embodiment 1

[0024] The conductive ink of Example 1 of the present invention includes the following raw materials in parts by weight: 20 parts of conductive carbon black, 40 parts of gum arabic, 40 parts of water, 0.5 parts of glycerin, and 0.5 parts of potassium sorbate.

[0025] The preparation method of embodiment 1 conductive ink of the present invention is as follows:

[0026] Step 1: Add gum arabic into water, stir and dissolve at 60-80°C, add glycerin and potassium sorbate and continue stirring to form a uniform transparent solution;

[0027] Step 2: Add conductive carbon black to the transparent solution obtained in step 1, stir at 50-60°C, grind the conductive carbon black until the ink fineness is 3-5 μm, and obtain the conductive ink of Example 1 .

Embodiment 2

[0029] The conductive ink of Example 2 of the present invention includes the following raw materials in parts by weight: 5 parts of conductive carbon black, 30 parts of starch, 40 parts of water, 0.2 part of sorbitol, 0.4 part of sodium benzoate, and 20 parts of zinc powder.

[0030] The preparation method of embodiment 2 conductive ink of the present invention is as follows:

[0031] Step 1: Add starch to water, stir and dissolve at 70-90°C, add sorbitol and sodium benzoate and continue stirring to form a uniform transparent solution

[0032] Step 2: Add conductive carbon black to the solution obtained in step 1, stir at 70-80°C, grind the conductive carbon black until the ink fineness is 5-10 μm, and obtain the conductive ink of Example 2.

Embodiment 3

[0034] The conductive ink of Example 3 of the present invention includes the following raw materials in parts by weight: 20 parts of conductive carbon black, 30 parts of agar, 30 parts of water, 0.5 parts of propylene glycol, 0.2 parts of calcium propionate, and 20 parts of terpene resin.

[0035] The preparation method of embodiment 3 conductive ink of the present invention is as follows:

[0036] Step 1: Add agar into water, stir and dissolve at 70-80°C, add propylene glycol, calcium propionate and terpene resin and continue stirring to form a uniform transparent solution;

[0037] Step 2: Add conductive carbon black to the transparent solution obtained in step 1, stir at 70-80°C, grind the conductive carbon black until the ink fineness is 10-15 μm, and obtain the conductive ink of Example 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com