Preparing method for lead-sulfide nanocrystalline material

A nanocrystalline material, lead sulfide technology, applied in the direction of lead sulfide, nanotechnology, analytical materials, etc., can solve the problems of complex preparation process and limitations, and achieve the effect of simple method, huge application value and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

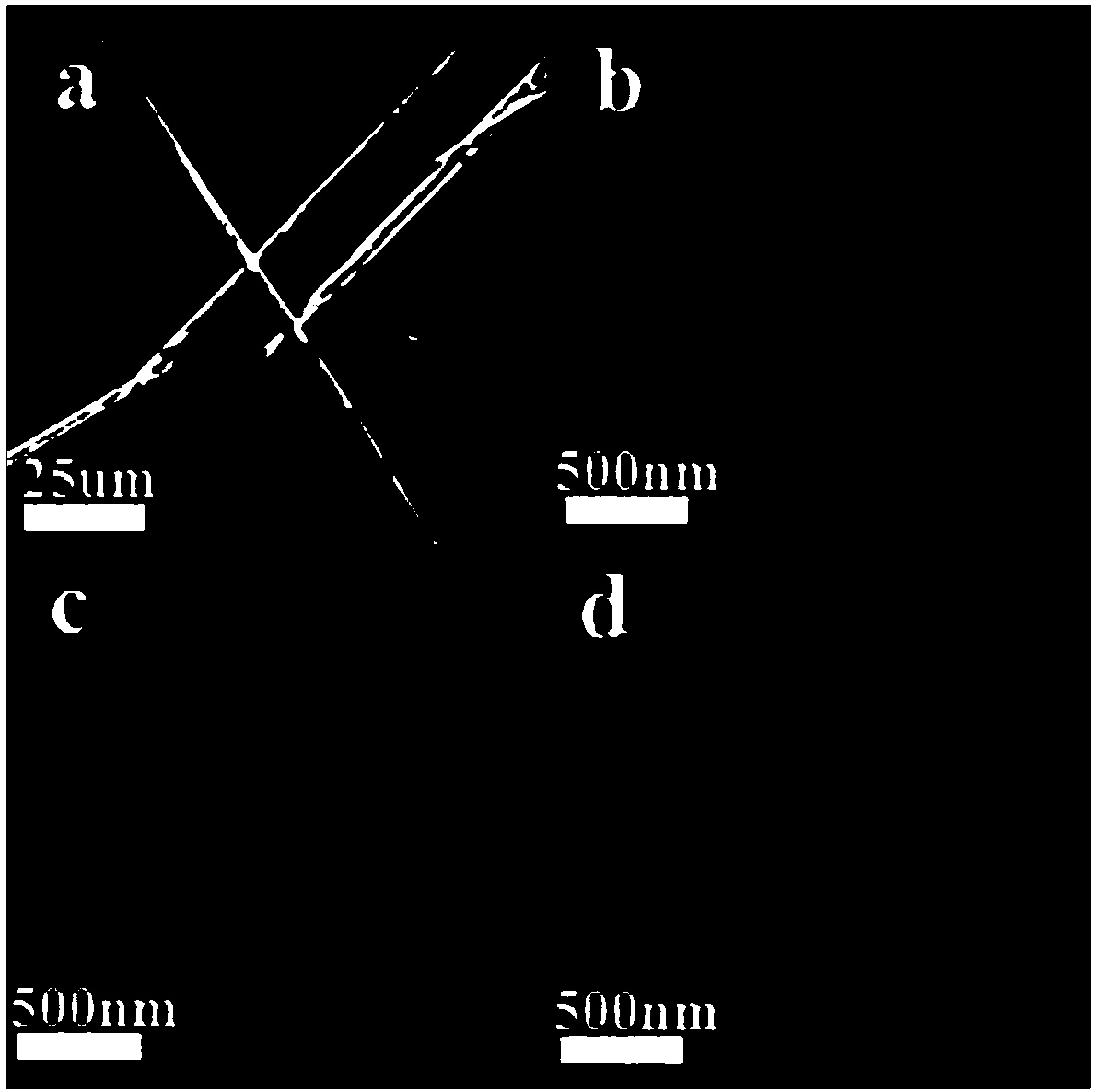

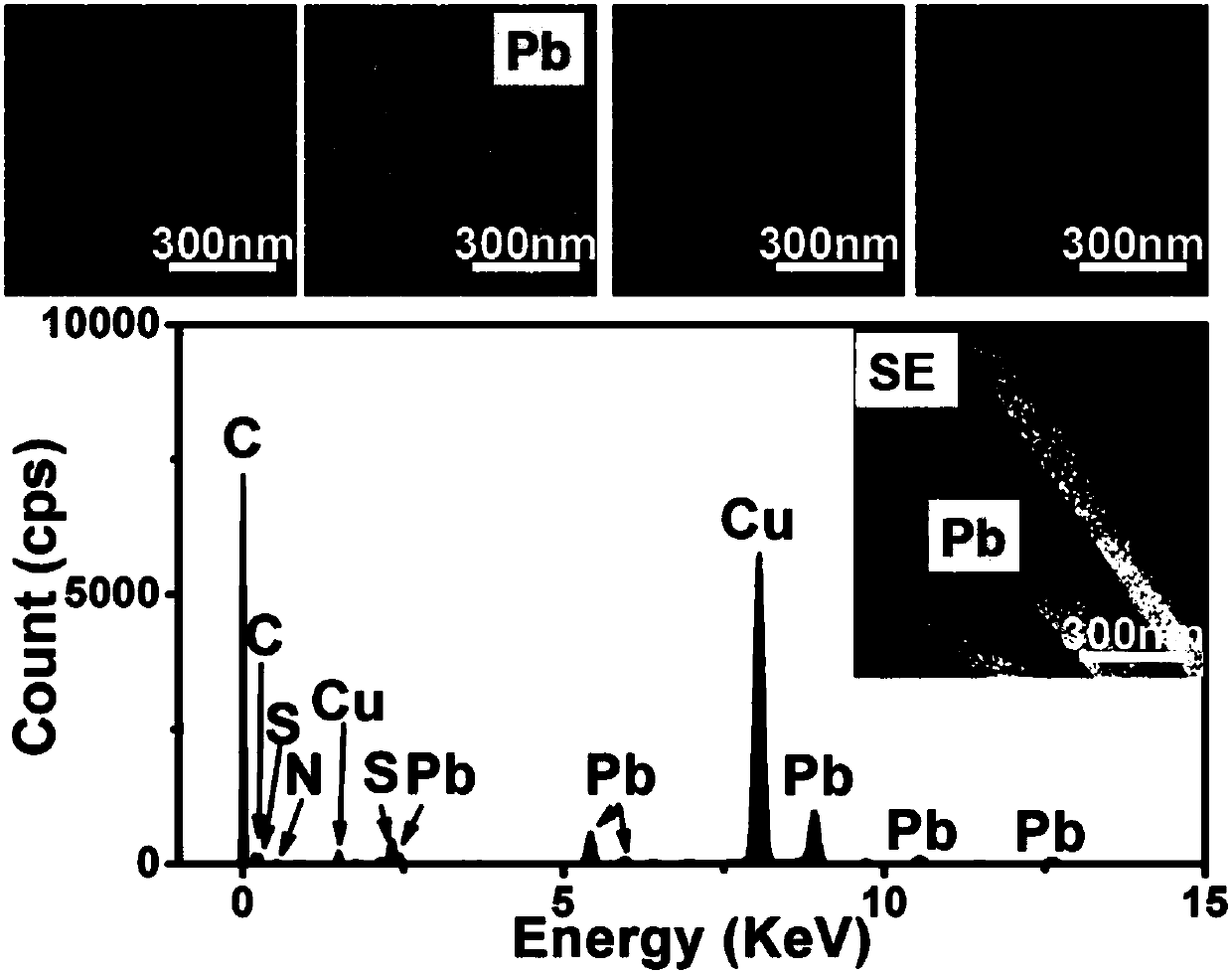

Image

Examples

Embodiment 1

[0039] S1: Put 0.1mol of lead nitrate and 0.2mol of sodium dimethylaminodithioformate (sodium thiocarbamate) into a 200ml beaker respectively, add 100ml of high-purity water, stir, then sonicate for 30min, let it react completely, and then filter it with suction. Wash and dry at 120°C for 2 hours to obtain a white lump product, grind it into powder in a mortar, pack it in a glass bottle, and place it in a drying oven for use.

[0040] S2: Weigh out 0.05 mmol of the precursor lead dimethylaminodithiocarbamate, measure 50 ml of ethylene glycol, and put it into a 50 ml long-necked double-necked round bottom flask. It was placed in an ultrasonic cleaner for 20 min and heated to 50°C.

[0041] S3: Under the ultrasonic stirring power of 200W, the precursor reaction solution obtained in step S2 is heated to 120°C by microwave at room temperature, and the heating temperature gradient is 35-40°C / min to obtain the first reaction solution; the first reaction solution is continued Microw...

Embodiment 2-4

[0044] The only difference with Example 1 is that the weighed amounts of lead dimethyl dithiocarbamate in this Example 2-4 are respectively 0.01mol, 0.03mol and 0.06mol, and others are the same as Example 1. To repeat, the obtained lead sulfide nanocrystalline materials are respectively named as PbS-2, PbS-3 and PbS-4.

Embodiment 5-7

[0046] The only difference from Example 1 is that the powers of ultrasonic stirring in Examples 5-7 are respectively 100W, 300W and 400W, and others are the same as in Example 1, and will not be repeated here, and the obtained lead sulfide nanocrystalline materials are respectively named are PbS-5, PbS-5 and PbS-7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com