Forming method of hard alloy threaded hole

A technology of cemented carbide and forming method, applied in metal processing equipment, tangent devices, manufacturing tools, etc., can solve the problems of high processing difficulty, high cost and high hardness, and achieve the effect of avoiding processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

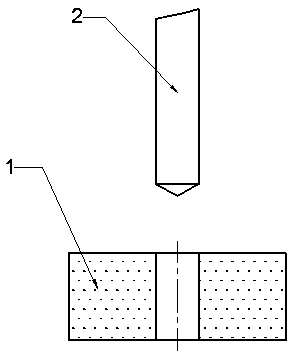

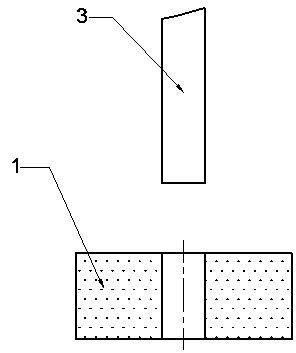

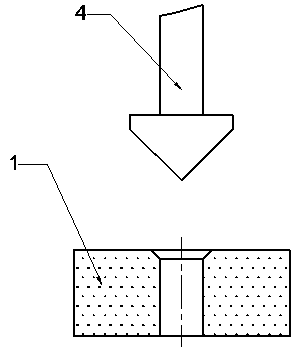

[0022] Such as figure 1 Shown, threaded hole processing of the present invention works and implements like this, it is characterized in that method steps are as follows:

[0023] 1. Drilling: Use a small-diameter drill to drill the bottom hole. Since the surface of the hole processed by the drill is relatively rough, the diameter of the bottom hole drilled by the drill is required to be smaller than the small diameter of the thread design.

[0024] 2. Reaming: Use a straight shank milling cutter to expand the inner hole processed by the drill bit. The surface of the inner hole is required to be smooth and flat, and the size is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com