Manufacturing method of low-melting-point glass optical fiber perform coating sleeve pipe

A low-melting-point glass and optical fiber preform technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of large interface loss and complex manufacturing process, reduce impurities and bubble loss, simple and fast operation, and avoid bubble streaks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

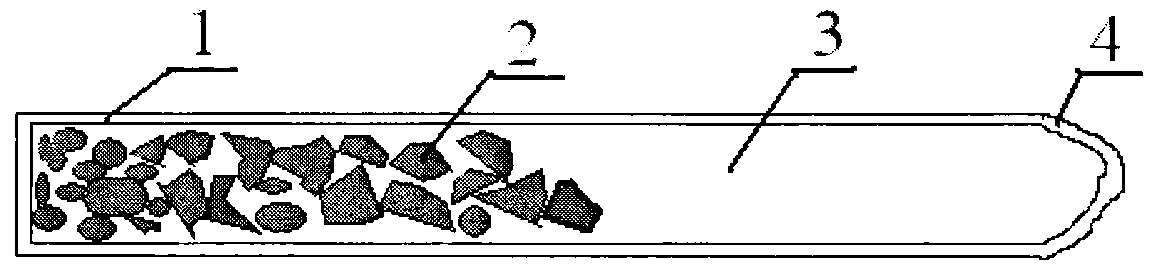

[0026] A method for preparing a cladding sleeve of a tellurite glass optical fiber preform, comprising the following steps:

[0027] (1) melting tellurate glass, cooling and crushing for subsequent use;

[0028] (2) Design the inner and outer diameters of the tellurite glass casing, and select a quartz tube of the corresponding size;

[0029] (3) Calculate and accurately weigh the tellurite glass and then pack it into a quartz tube;

[0030] (3) Heating the bottom of the charged quartz tube to 150-300°C, and then sealing it with flame;

[0031] (4) Put the sealed quartz tube into a swing furnace, slowly heat up to melt the glass in the tube to a liquid state;

[0032] (5) Turn on the swing switch of the electric furnace and swing for about 10 minutes to make the glass liquid mix evenly;

[0033] (6) Turn on the electric furnace, quickly take out the quartz tube and put it horizontally into the rotating device, fix the quartz tube and rotate it at a speed of 3000 rpm for 3 t...

Embodiment 2

[0037] A method for preparing the cladding sleeve of an oxyfluorine tellurate glass optical fiber preform, comprising the following steps:

[0038] (1) melting oxyfluorine tellurate glass, cooling and crushing for subsequent use;

[0039] (2) Design the inner and outer diameters of the tellurite glass casing, and select a quartz tube of the corresponding size;

[0040] (3) Calculate and accurately weigh the tellurite glass and then pack it into a quartz tube;

[0041] (3) Heat the bottom of the charged quartz tube to 150-200°C, vacuumize to make the pressure in the tube lower than one atmospheric pressure, and then seal it with flame;

[0042] (4) Put the sealed quartz tube into a swing furnace, slowly heat up to melt the glass in the tube to a liquid state;

[0043] (5) Turn on the swing switch of the electric furnace and swing for about 30 minutes to make the glass liquid mix evenly;

[0044] (6) Turn on the electric furnace, quickly take out the quartz tube and put it ho...

Embodiment 3

[0048] A method for preparing a cladding sleeve of a chalcogenide optical fiber preform, comprising the steps of:

[0049] (1) melting chalcogenide glass, cooling and crushing for subsequent use;

[0050] (2) Design the inner and outer diameters of the chalcogenide glass casing, and select a quartz tube of the corresponding size;

[0051] (3) Calculate and accurately weigh the tellurite glass and then pack it into a quartz tube;

[0052] (3) Heat the bottom of the charged quartz tube to 90-250°C, and vacuumize the tube to make the pressure in the tube lower than 10 -2 Pa, and then sealed with flame;

[0053] (4) Put the sealed quartz tube into a swing furnace, slowly heat up to melt the glass in the tube to a liquid state;

[0054] (5) Turn on the swing switch of the electric furnace to swing for more than 1 hour to make the glass liquid mix evenly;

[0055] (6) Turn on the electric furnace, quickly take out the quartz tube and put it horizontally into the rotating device,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com