A coating with both responsive drug release and antibacterial functions and its preparation method

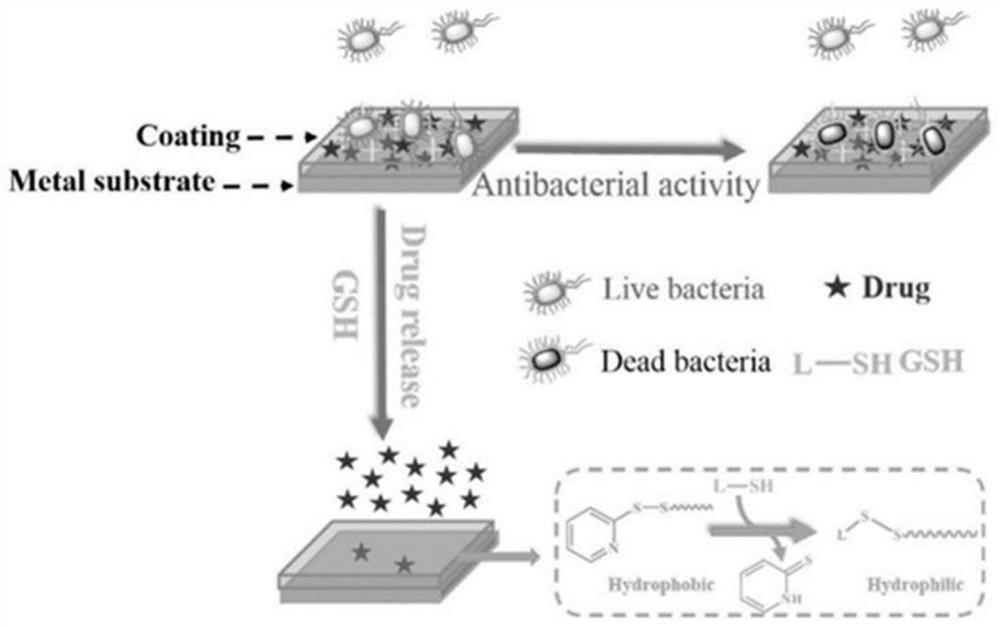

A responsive and functional technology, applied in the field of antibacterial coatings and antibacterial surfaces, can solve the problems of bacterial drug resistance and uncontrollable drug release, and achieve high drug loading efficiency, controllable coating preparation process, and enhanced hydrophilicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

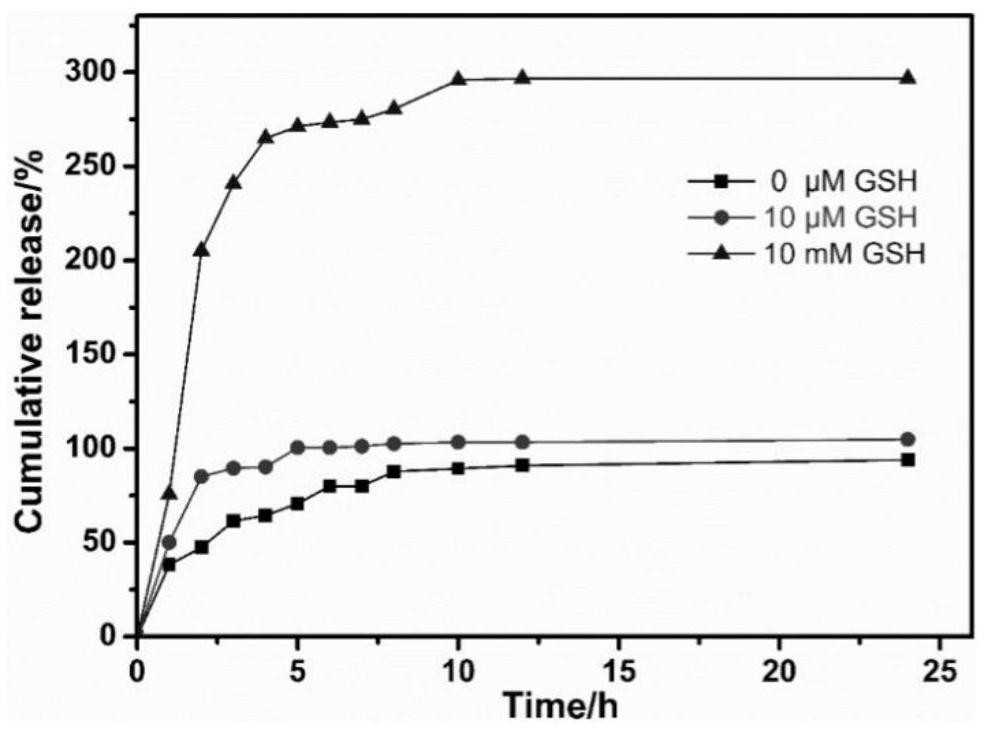

[0025] (1) Preparation of redox-responsive random copolymer: Weigh 0.288g PDSA, 0.406g DMAC12 and 0.0059g 2,2-azobisisobutyrocyanide into a round bottom flask in turn, add 15mL N,N -Dimethylformamide is used as a solvent, nitrogen gas is passed for 30 minutes, and the reaction is carried out at 70°C for 20 hours. The reaction solution is repeatedly precipitated in anhydrous ether three times, and vacuum-dried to obtain a redox-responsive random copolymer;

[0026] (2) Preparation of drug-loaded colloidal particles: Dissolve the random copolymer prepared in step (1) and the small molecule drug example paracetamol in N,N-dimethylformamide to form a 40 mg / mL solution, and the paracetamol concentration is 10 mg / mL mL, ultrapure water was added dropwise to the above solution at a volume ratio of 1:1, the random polymer self-assembled, and part of the paracetamol was coated in the random copolymer micelles to form redox-responsive drug-loaded micelles;

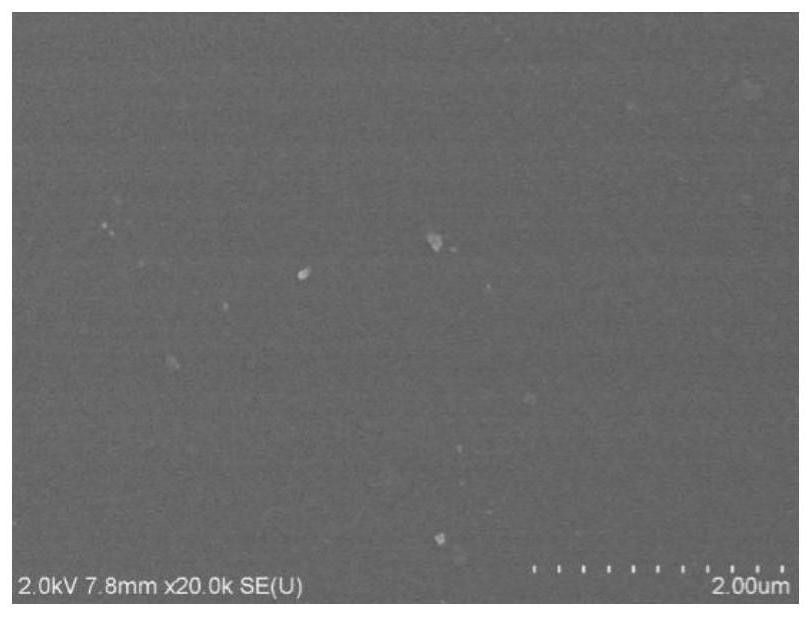

[0027] (3) Preparation of a ...

Embodiment 2

[0029] (1) Preparation of redox-responsive random copolymer: Weigh 0.48g PDSA, 0.4872g DMAC12, 0.08gMMA and 0.0059g 2,2-azobisisobutyrocyanide, add them to a round bottom flask in turn, add 20mL N,N-dimethylformamide was used as a solvent, nitrogen gas was passed for 30 minutes, and the reaction was carried out at 65°C for 24 hours. The reaction solution was repeatedly precipitated in anhydrous ether three times, and vacuum-dried to obtain a redox-responsive random copolymer;

[0030] (2) Preparation of drug-loaded colloidal particles: Dissolve the random copolymer prepared in step (1) and the small molecule drug example paracetamol in N,N-dimethylformamide to form a 40 mg / mL solution, and the paracetamol concentration is 10 mg / mL mL, ultrapure water was added dropwise to the above solution at a volume ratio of 1:1, the random polymer self-assembled, and part of the paracetamol was coated in the random copolymer micelles to form redox-responsive drug-loaded micelles;

[0031] ...

Embodiment 3

[0033] (1) Preparation of redox-responsive random copolymer: Weigh 0.48g PDSA, 0.4872g DMAC12, 0.08gMMA and 0.0059g 2,2-azobisisobutyrocyanide, add them to a round bottom flask in turn, add 20mL N,N-dimethylformamide was used as a solvent, nitrogen gas was passed for 30 minutes, and the reaction was carried out at 65°C for 24 hours. The reaction solution was repeatedly precipitated in anhydrous ether three times, and vacuum-dried to obtain a redox-responsive random copolymer;

[0034] (2) Preparation of drug-loaded colloidal particles: Dissolve the random copolymer prepared in step (1) and the small molecule drug example paracetamol in N,N-dimethylformamide to form a 20 mg / mL solution, and the paracetamol concentration is 5 mg / mL mL, ultrapure water was added dropwise to the above solution at a volume ratio of 1:2, the random polymer self-assembled, and part of the paracetamol was coated in the random copolymer micelles to form redox-responsive drug-loaded micelles;

[0035](3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com