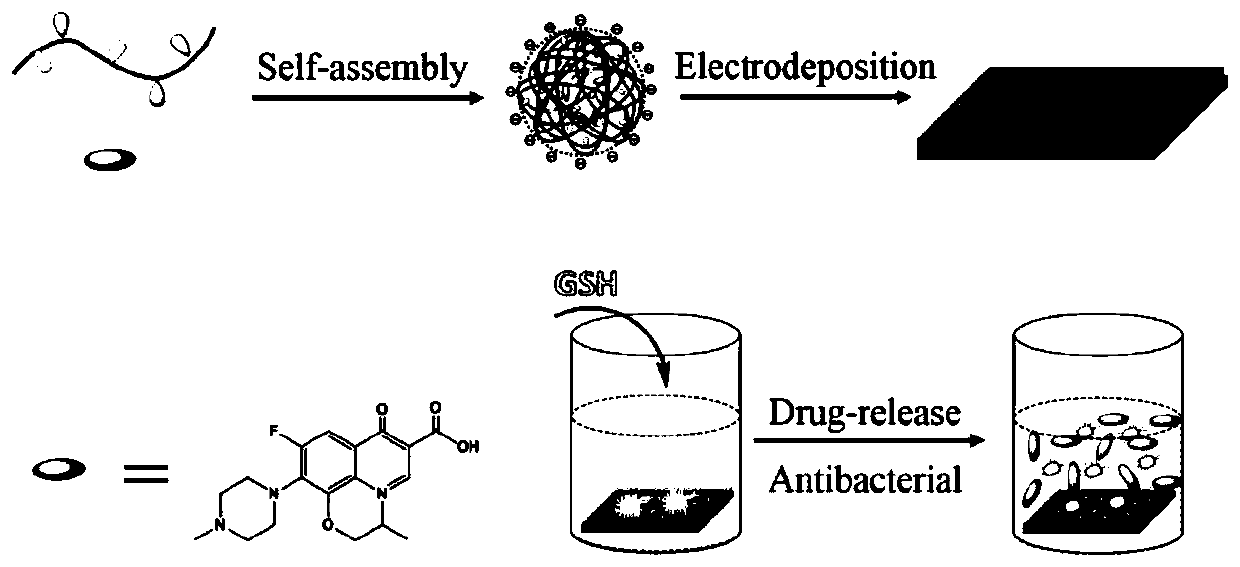

A kind of intelligent antibacterial coating with good cell compatibility and preparation method thereof

An antibacterial coating and compatibility technology, which is applied in the field of intelligent antibacterial coating and its preparation, can solve the problems of uncontrollable release of antibacterial agents, bacterial drug resistance, and affecting cell growth, etc. High loading efficiency and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

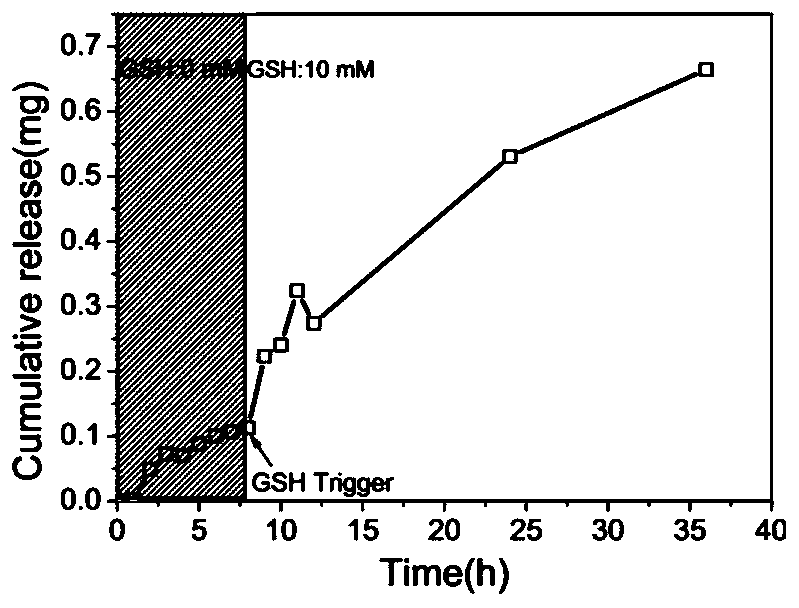

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of redox stimulus-responsive γ-polyglutamic acid (γ-PGA-PDA): Weigh 2mmol of γ-polyglutamic acid and dissolve in 35mL dimethyl sulfoxide, heat to 70℃, stir to dissolve, and cool down To 30°C; add 2mmolHOBt and 2mmolEDC to activate for 10min, then add 2mmol 2-(2-pyridyldisulfide) ethylamine hydrochloride (PDA) and react at 30°C for 24h. After the reaction is completed, the reaction solution is repeatedly precipitated in absolute ethanol, and the product can be obtained by dialysis.

[0030] (2) Preparation of dopamine-modified redox stimulus-responsive γ-polyglutamic acid (γ-PGA-PDA-DA): weigh 2mmol γ-PGA-PDA into a round bottom flask, add 35mL dimethyl sulfoxide, and increase the temperature Dissolve in half at 70°C, and cool to 30°C; add 4mmolHOBt and 2mmolEDC to activate for 10min, then add 2mmol dopamine hydrochloride (DA) and react at 30°C for 24h. After the reaction is completed, the reaction solution is repeatedly precipitated and dialyzed in absolut...

Embodiment 2

[0034] (1) Preparation of redox stimulus-responsive γ-polyglutamic acid (γ-PGA-PDA): Weigh 2mmol of γ-polyglutamic acid and dissolve in 35mL dimethyl sulfoxide, heat to 70℃, stir to dissolve, and cool down To 25°C; add 2mmolHOBt and 2mmolEDC to activate for 10min, then add 3mmol 2-(2-pyridyldisulfide) ethylamine hydrochloride (PDA) and react at 30°C for 24h. After the reaction is completed, the reaction solution is repeatedly precipitated in absolute ethanol, and the product can be obtained by dialysis.

[0035] (2) Preparation of dopamine-modified redox stimulus-responsive γ-polyglutamic acid (γ-PGA-PDA-DA): weigh 2mmol γ-PGA-PDA into a round bottom flask, add 35mL dimethyl sulfoxide, and increase the temperature Dissolve in half at 70°C, and cool to 25°C; add 4mmolHOBt and 2mmolEDC to activate for 10min, then add 3mmol dopamine hydrochloride (DA) and react at 30°C for 24h. After the reaction is completed, the reaction solution is repeatedly precipitated and dialyzed in absolut...

Embodiment 3

[0039] (1) Preparation of redox stimulus-responsive γ-polyglutamic acid (γ-PGA-PDA): Weigh 2mmol of γ-polyglutamic acid and dissolve in 35mL dimethyl sulfoxide, heat to 70℃, stir to dissolve, and cool down To 25°C; add 3mmolHOBt and 2mmolEDC to activate for 20min, then add 3mmol 2-(2-pyridyldisulfide) ethylamine hydrochloride (PDA) and react at 30°C for 20h. After the reaction is completed, the reaction solution is repeatedly precipitated in absolute ethanol, and the product can be obtained by dialysis.

[0040] (2) Preparation of dopamine-modified redox stimulus-responsive γ-polyglutamic acid (γ-PGA-PDA-DA): weigh 2mmol γ-PGA-PDA into a round bottom flask, add 35mL dimethyl sulfoxide, and increase the temperature To 70°C, halve to dissolve, and cool to 25°C;

[0041] Add 4mmolHOBt and 2mmolEDC to activate for 20min, then add 3mmol dopamine hydrochloride (DA) and react at 30°C for 24h. After the reaction is completed, the reaction solution is repeatedly precipitated and dialyzed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com