Method for preparing environment-friendly polylactic-acid composite material with high tensile strength

A technology of high tensile strength and composite materials, which is applied in the field of polymer composite material preparation, can solve the problems of low tensile strength and achieve the effects of increased tensile strength, excellent biodegradability, and promotion of dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

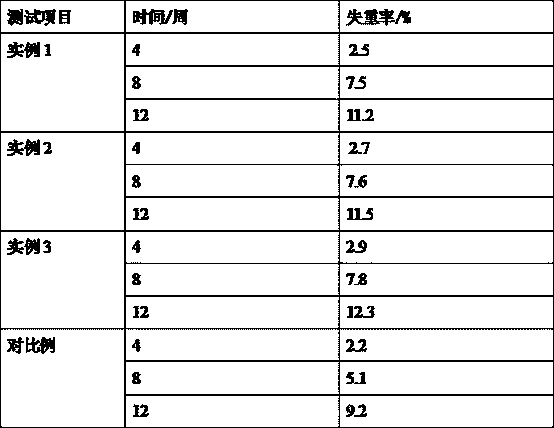

Examples

example 1

[0023]Weigh 80g of potatoes and put them into a grinder to grind for 10 minutes. After grinding, potato powder is obtained. Add the potato powder to the fermenter, then add pig manure and biogas slurry of the same quality as the potato powder and mix, and ferment at 35°C for 10 days. Remove the filter residue to obtain a lactate solution, add 100mL of sulfuric acid solution with a mass fraction of 30% to the lactate solution, mix and react for 12min, and obtain self-made lactic acid after filtration, add 20mL absolute ethanol and 12mL mass fraction to the self-made lactic acid to obtain Mix 30% hydrogen peroxide, and polycondense at 30°C for 1 hour to obtain self-made polylactic acid. For later use, weigh 8g of salicylic acid powder and put it into a three-necked flask filled with 30mL of ether, then add 3mL of boron trifluoride ether to mix. Heating and reacting under reflux for 2h, after cooling to room temperature, washing with 30% sodium chloride solution for 6 times, then ...

example 2

[0025] Weigh 90g of potatoes and put them into a grinder to grind for 11 minutes. After grinding, potato powder is obtained. Add the potato powder to the fermenter, then add pig manure and biogas slurry of the same quality as the potato powder to mix, and ferment at 40°C for 11 days. Remove the filter residue to obtain a lactate solution, add 110mL of sulfuric acid solution with a mass fraction of 30% to the lactate solution, mix and react for 14min, and obtain self-made lactic acid after filtration, add 30mL absolute ethanol and 14mL mass fraction to the self-made lactic acid to obtain Mix 30% hydrogen peroxide, and polycondense at 40°C for 1.5h, which is self-made polylactic acid. For later use, weigh 9g of salicylic acid powder and put it into a three-necked flask filled with 40mL of ether, then add 4mL of boron trifluoride in ether to mix , heated and reacted for 3 hours under reflux, and after cooling to room temperature, washed 7 times with 30% sodium chloride solution, t...

example 3

[0027] Weigh 100g of potatoes and put them into a grinder to pulverize for 12 minutes. After pulverization, potato powder is obtained. Add the potato powder to the fermenter, then add pig manure and biogas slurry of the same quality as the potato powder to mix, and ferment at 45°C for 12 days. Remove the filter residue to obtain a lactate solution, add 120mL of sulfuric acid solution with a mass fraction of 30% to the lactate solution, mix and react for 16min, and obtain self-made lactic acid after filtration, add 40mL absolute ethanol and 16mL mass fraction to the self-made lactic acid to obtain Mix 30% hydrogen peroxide, and polycondense at 50°C for 2 hours to obtain self-made polylactic acid. For later use, weigh 10g of salicylic acid powder and put it into a three-necked flask filled with 50mL of ether, and then add 5mL of boron trifluoride ether to mix. Heating and reacting under reflux for 4h, after cooling to room temperature, washing with 30% sodium chloride solution fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com