Preparation method of unbleached pulp for high-strength corrugated paper

A technology of natural color pulp and corrugated paper, applied in pulp beating/refining methods, non-woody plant/crop pulp, paper, etc., can solve the problems of low ring pressure index and long breakage of high-strength corrugated paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

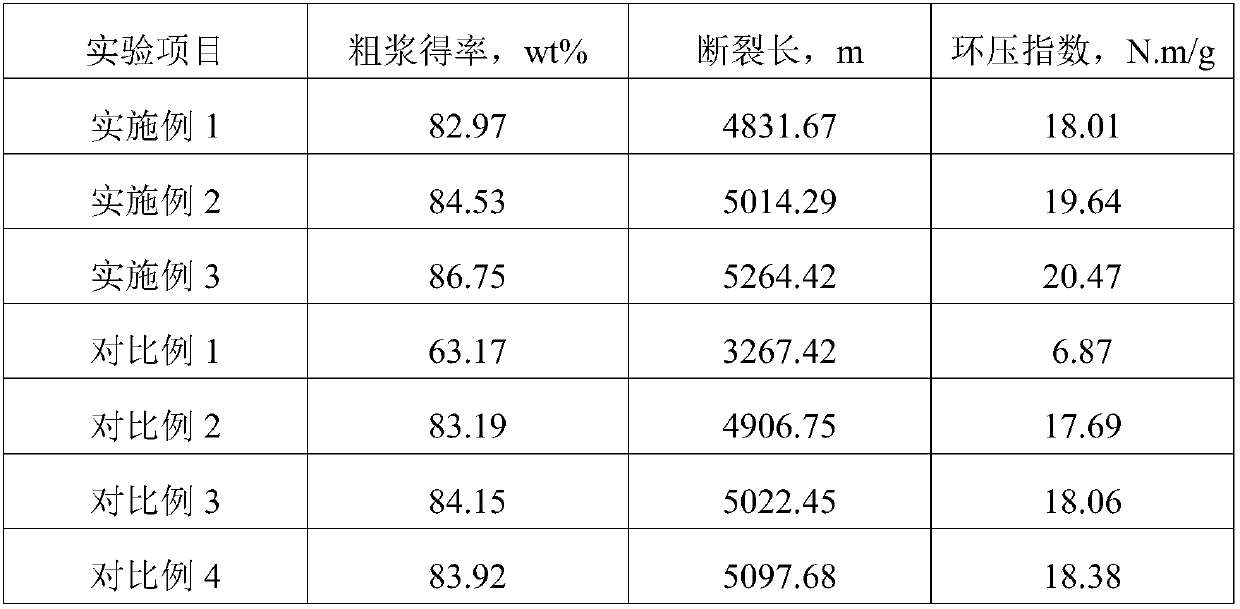

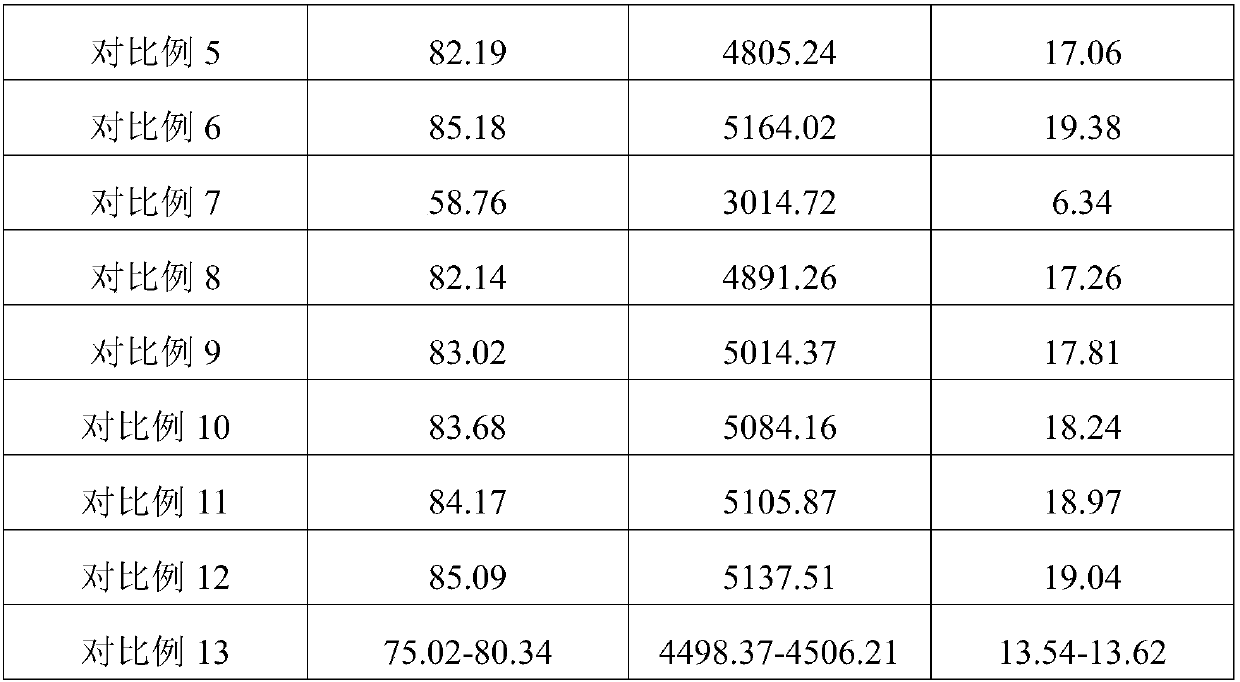

Examples

preparation example Construction

[0027] In an embodiment, the preparation method of the high-strength corrugated paper includes the following steps:

[0028] S1: Grinding the bagasse, and transporting the resulting crushed product to the primary treatment liquid, the weight ratio of the bagasse crushed product to the primary treatment liquid is 1:1.2-4, and the primary treatment liquid is expressed in parts by weight as a unit, including the following raw materials: polyethylene glycol 3-6 parts, fatty alcohol polyoxyethylene ether 4-8 parts, fatty alcohol polyoxyethylene ether ammonium sulfate 1-2 parts, sodium alkyl succinate sulfonate 2- 4 parts, 0.1-0.2 parts of cellulase, 50-120 parts of water, soaking for 20-30min at an ultrasonic power of 80-120W and a temperature of 40-50°C, and then filtering to obtain the soaking material a;

[0029] S2: Transport the immersion material a prepared in step S1 to the secondary treatment liquid, the weight ratio of the immersion material a to the secondary treatment li...

Embodiment 1

[0033] A method for preparing high-strength corrugated paper, comprising the following steps:

[0034] S1: Grinding the bagasse, and conveying the obtained pulverized product to the primary treatment liquid, the weight ratio of the bagasse pulverized product to the primary treatment liquid is 1:1.3, and the primary treatment liquid is in parts by weight , including the following raw materials: 3 parts of polyethylene glycol, 5 parts of fatty alcohol polyoxyethylene ether, 1 part of fatty alcohol polyoxyethylene ether ammonium sulfate, 2 parts of sodium alkyl succinate sulfonate, 0.1 part of cellulase, 50 parts of water Parts were soaked for 30 minutes at an ultrasonic power of 80W and a temperature of 40°C, and then filtered to obtain the impregnated material a;

[0035] S2: Transport the immersion material a prepared in step S1 to the secondary treatment liquid, the weight ratio of the immersion material a to the secondary treatment liquid is 1:4.5, and the secondary treatmen...

Embodiment 2

[0039] A method for preparing high-strength corrugated paper, comprising the following steps:

[0040] S1: Grinding the bagasse, and transporting the obtained pulverized product to the primary treatment liquid, the weight ratio of the bagasse pulverized product to the primary treatment liquid is 1:4, and the primary treatment liquid is in parts by weight , including the following raw materials: 6 parts of polyethylene glycol, 8 parts of fatty alcohol polyoxyethylene ether, 2 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 4 parts of sodium alkyl succinate sulfonate, 0.2 part of cellulase, 120 parts of water Parts were soaked for 20 minutes at an ultrasonic power of 120W and a temperature of 50°C, and then filtered to obtain the impregnated material a;

[0041] S2: Transport the immersion material a prepared in step S1 to the secondary treatment liquid, the weight ratio of the immersion material a to the secondary treatment liquid is 1:12.6, and the secondary tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com