Primary treatment solution for producing high strength corrugated paper by utilizing bleaching process and application thereof

A technology for treating liquid and corrugated paper, applied in fiber raw material processing, paper, papermaking, etc., can solve the problems of low ring pressure index and long breakage of high-strength corrugated paper, and achieve the effect of reducing pollution and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

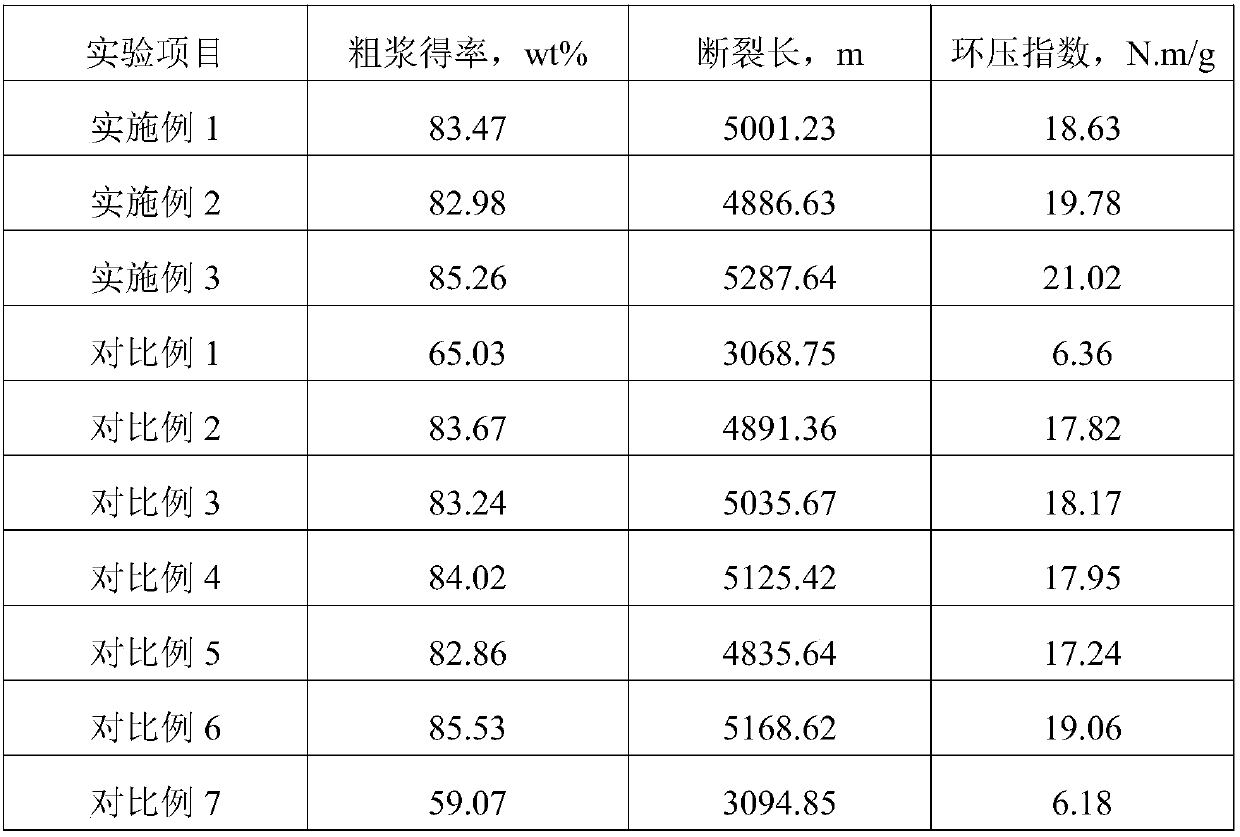

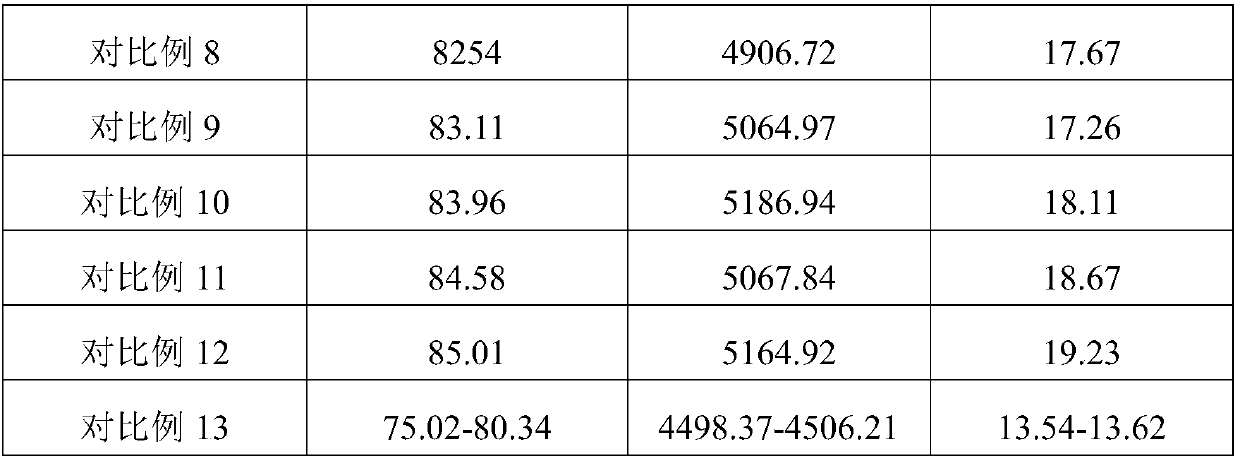

Examples

Embodiment 1

[0034] A method for preparing high-strength corrugated paper produced by a bleaching process, comprising the following steps:

[0035] S1: Grinding the bagasse, and transporting the obtained pulverized product into the primary treatment liquid, the weight ratio of the bagasse pulverized product to the primary treatment liquid is 1:1.3, and the primary treatment liquid is in parts by weight , including the following raw materials: 8 parts of stearamide, 5 parts of fatty alcohol polyoxyethylene ether, 1.5 parts of sodium dodecylbenzenesulfonate, 2.4 parts of sodium alkyl succinate sulfonate, 0.1 part of cellulase, 70 parts of water Parts were soaked for 30 minutes at an ultrasonic power of 80W and a temperature of 40°C, and then filtered to obtain the impregnated material a;

[0036] S2: Transport the immersion material a prepared in step S1 to the secondary treatment liquid, the weight ratio of the immersion material a to the secondary treatment liquid is 1:4.5, and the seconda...

Embodiment 2

[0040] A method for preparing high-strength corrugated paper produced by a bleaching process, comprising the following steps:

[0041] S1: Grinding the bagasse, and transporting the obtained pulverized product to the primary treatment liquid, the weight ratio of the bagasse pulverized product to the primary treatment liquid is 1:4, and the primary treatment liquid is in parts by weight , including the following raw materials: 12 parts of stearamide, 9 parts of fatty alcohol polyoxyethylene ether, 2.5 parts of sodium dodecylbenzenesulfonate, 4.5 parts of sodium alkyl succinate sulfonate, 0.2 part of cellulase, 160 parts of water , soaking for 20 minutes at an ultrasonic power of 120W and a temperature of 50°C, and then filtering to obtain the impregnated material a;

[0042] S2: Transport the immersion material a prepared in step S1 to the secondary treatment liquid, the weight ratio of the immersion material a to the secondary treatment liquid is 1:12.6, and the secondary trea...

Embodiment 3

[0046] A method for preparing high-strength corrugated paper produced by a bleaching process, comprising the following steps:

[0047] S1: Grinding the bagasse, and conveying the obtained pulverized product to the primary treatment liquid, the weight ratio of the bagasse pulverized product to the primary treatment liquid is 1:3, and the primary treatment liquid is in parts by weight , including the following raw materials: 10 parts of stearamide, 8 parts of fatty alcohol polyoxyethylene ether, 2 parts of sodium dodecylbenzenesulfonate, 3.5 parts of sodium alkyl succinate sulfonate, 0.1 part of cellulase, 120 parts of water , soaking for 25 minutes at an ultrasonic power of 100W and a temperature of 45°C, and then filtering to obtain the impregnated material a;

[0048] S2: Transport the immersion material a prepared in step S1 to the secondary treatment liquid, the weight ratio of the immersion material a to the secondary treatment liquid is 1:8, and the secondary treatment li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com