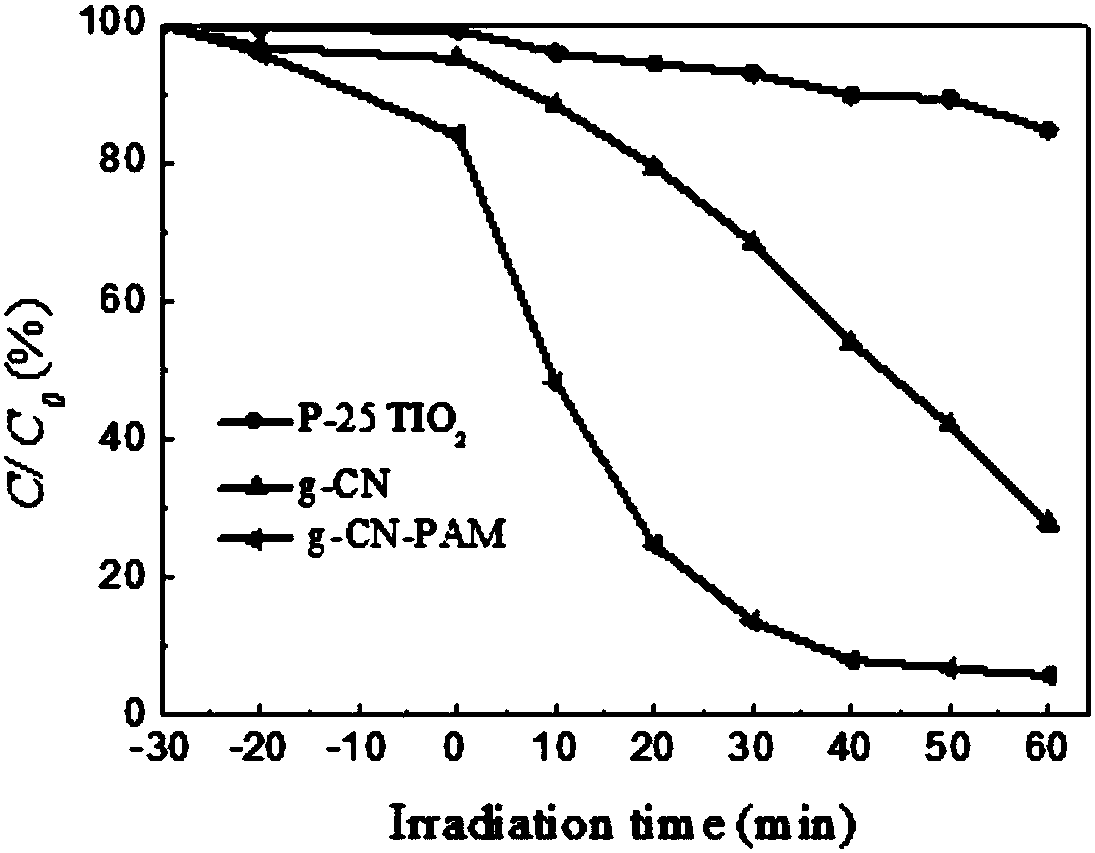

Preparation method of jellyfish-shaped carbon nitride photocatalytic material with high specific surface area

A technology of high specific surface area, photocatalytic material, applied in the field of preparation of high specific surface area jellyfish-like carbon nitride photocatalytic material, can solve the problems such as hindering photo-generated electron-hole separation photocatalytic process, photocatalytic limitation, etc., to achieve enhanced Photocatalytic effect, improving reaction rate, and the effect of strong degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Press to set high specific surface area jellyfish-like g-C 3 N 4 The mass composition percentage of melamine and polyacrylamide were weighed according to the ratio of 4:0.7, and a mixed solution composed of 20 ml of deionized water was added.

[0023] 2. Stir on a magnetic stirrer for 35 min, and then sonicate for 45 min. Finally, the obtained precipitate is centrifuged and dried under vacuum at 60° C. for 12 h.

[0024] 3. The dried precursor was added to a muffle furnace, and calcined at a high temperature of 550° C. (heating rate: 20° C. / min) for 100 min to obtain a brown solid.

[0025] 4. When the temperature drops to 300 °C, mix with carbon black according to the mass composition percentage of 8:3, stir evenly, and then grind it into a uniform powder with an agate mortar to obtain a jellyfish-like g-C with high specific surface area. 3 N 4 photocatalytic materials.

Embodiment 2

[0027] 1. Press to set high specific surface area jellyfish-like g-C 3 N 4 The mass composition percentage of melamine and polyacrylamide was weighed according to the ratio of 6:1, and a mixed solution composed of 20 ml of deionized water was added.

[0028] 2. Stir on a magnetic stirrer for 45 min, and then sonicate for 40 min. Finally, the obtained precipitate is centrifuged and dried in vacuum at 60° C. for 11 h.

[0029] 3. The dried precursor was added to a muffle furnace, and calcined at a high temperature of 560° C. (heating rate: 20° C. / min) for 120 min to obtain a brown solid.

[0030] 4. When the temperature drops to 305 °C, mix with carbon black according to the mass composition percentage of 10:4, stir evenly, and then grind it into a uniform powder with an agate mortar to obtain a jellyfish-like g-C with high specific surface area. 3 N 4 photocatalytic materials.

Embodiment 3

[0032] 1. Press to set high specific surface area jellyfish-like g-C 3 N 4 The mass composition percentage of melamine and polyacrylamide were weighed according to the ratio of 5:0.8, and a mixed solution composed of 20 ml of deionized water was added.

[0033] 2. Stir on a magnetic stirrer for 40 min, and then ultrasonicate for 50 min. Finally, the obtained precipitate is centrifuged and dried under vacuum at 60° C. for 13 h.

[0034] 3. The dried precursor was added to a muffle furnace, and calcined at a high temperature of 580° C. (heating rate: 20° C. / min) for 120 min to obtain a brown solid.

[0035]4. When the temperature drops to 300°C, mix with carbon black according to the mass composition percentage of 9:4, stir evenly, and then grind it into a uniform powder with an agate mortar to obtain a jellyfish-like g-C with high specific surface area. 3 N 4 photocatalytic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com