Threaded rod type double-acting acceleration tool

A double-acting, screw-type technology, applied in the direction of drilling with vibration, can solve problems such as affecting the drilling speed, damage to the drill bit, wellbore wall friction, etc., achieve high energy conversion efficiency, eliminate stick-slip and stuck pipe, reverse low impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

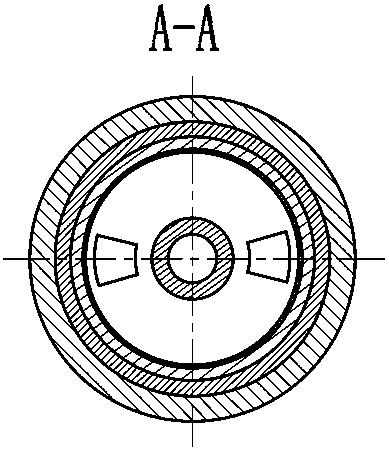

[0021] Referring to the accompanying drawings, the screw-type double-action speed-up tool is composed of a power assembly, a cardan shaft assembly, a transmission assembly and an impact assembly, and the front end of the power assembly is connected to the cardan shaft assembly, the transmission assembly, and the impact assembly in sequence. Assembly; the power assembly includes an upper joint 1, an anti-drop lock nut 2, an anti-drop connecting rod 3, a stator casing 4, a rubber bush 5 and a screw rotor 6, and the rubber bush 5 is installed on the stator casing 4 The interior consists of a screw stator. The screw rotor 6 and the screw stator mesh with each other. Driven by the drilling fluid, the rotor 6 is driven to rotate. The upper joint 1 is connected to the stator housing 4 through threads, and the front end of the anti-drop connecting rod 3 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com