Device for manufacturing super-fine denier-dumbbell-shaped flat fibers and manufacturing method thereof

A flat fiber, dumbbell-shaped technology, which is applied to the equipment for manufacturing ultra-fine denier dumbbell-shaped flat fibers and its manufacturing field, can solve problems such as low irregularity, and achieve the effect of preventing wire skipping and enhancing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

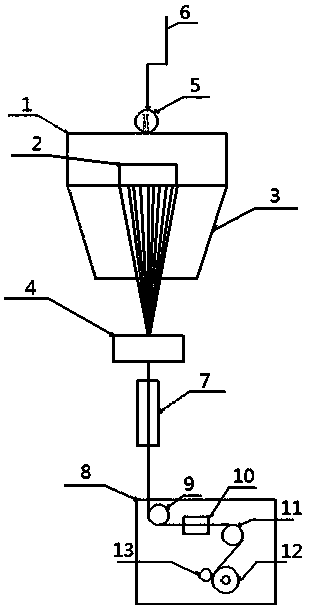

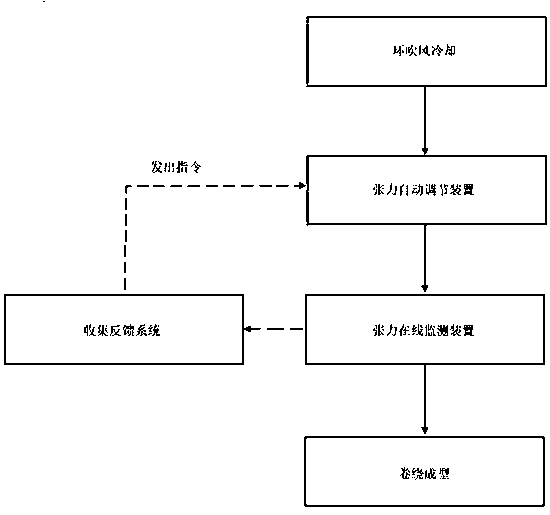

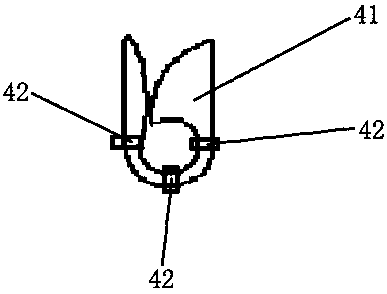

[0022] like Figure 1 to Figure 6 As shown, a kind of equipment that is used to manufacture superfine denier dumbbell-shaped flat fiber comprises spinning box body 1, metering pump 5, biphenyl evaporator, spinning assembly 2, and described spinning box body 1 is provided with melting body pipeline 6, the spinning assembly 2 is arranged under the inside of the spinning box 1, the ring blowing cooling device 3 is arranged under the spinning assembly 2, the oiling device 4 is arranged under the ring blowing cooling device 3, and the oiling device 4 is arranged below A spinning tunnel 7 is provided, and a winding machine 8 is arranged below the spinning tunnel 7, and a first godet 9, a network device 10, a second godet 11, a winding Bobbin 12 and pressure roll 13, the spinning assembly 2 includes an assembly sand cup 14 and a spinneret 16, a layer of 1400um twill mesh 15 is arranged between the assembly sand cup 14 and the spinneret 16, and the spinneret Silk plate 16 is provided...

Embodiment 2

[0024] like Figure 1 to Figure 6As shown, a kind of equipment that is used to manufacture superfine denier dumbbell-shaped flat fiber comprises spinning box body 1, metering pump 5, biphenyl evaporator, spinning assembly 2, and described spinning box body 1 is provided with melting body pipeline 6, the spinning assembly 2 is arranged under the inside of the spinning box 1, the ring blowing cooling device 3 is arranged under the spinning assembly 2, the oiling device 4 is arranged under the ring blowing cooling device 3, and the oiling device 4 is arranged below A spinning tunnel 7 is provided, and a winding machine 8 is arranged below the spinning tunnel 7, and a first godet 9, a network device 10, a second godet 11, a winding Bobbin 12 and pressure roll 13, the spinning assembly 2 includes an assembly sand cup 14 and a spinneret 16, a layer of 1400um twill mesh 15 is arranged between the assembly sand cup 14 and the spinneret 16, and the spinneret Silk plate 16 is provided ...

Embodiment 3

[0026] like Figure 1 to Figure 6 As shown, a kind of equipment that is used to manufacture superfine denier dumbbell-shaped flat fiber comprises spinning box body 1, metering pump 5, biphenyl evaporator, spinning assembly 2, and described spinning box body 1 is provided with melting body pipeline 6, the spinning assembly 2 is arranged under the inside of the spinning box 1, the ring blowing cooling device 3 is arranged under the spinning assembly 2, the oiling device 4 is arranged under the ring blowing cooling device 3, and the oiling device 4 is arranged below A spinning tunnel 7 is provided, and a winding machine 8 is arranged below the spinning tunnel 7, and a first godet 9, a network device 10, a second godet 11, a winding Bobbin 12 and pressure roll 13, the spinning assembly 2 includes an assembly sand cup 14 and a spinneret 16, a layer of 1400um twill mesh 15 is arranged between the assembly sand cup 14 and the spinneret 16, and the spinneret Silk plate 16 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com