Preparation method of melt-spun profiled polyvinyl alcohol fibers

A polyvinyl alcohol fiber and polyvinyl alcohol technology, which is applied in fiber processing, fiber chemical characteristics, rayon manufacturing and other directions, can solve the problems of large irregularity and difficulty in obtaining controllable cross-section, and achieves large irregularity and improved Small effect of spinnability and shear viscosity change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

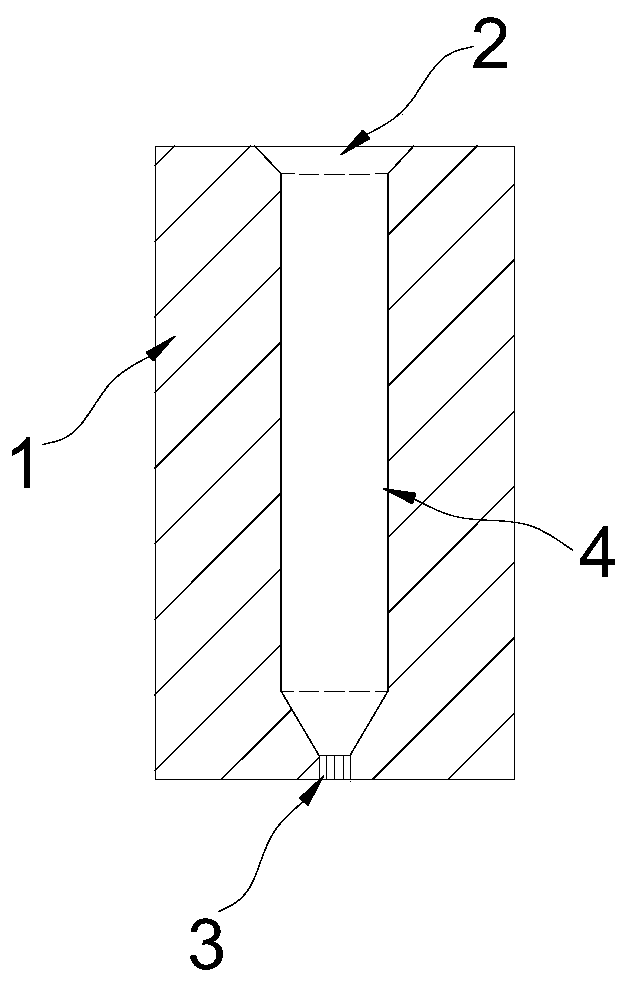

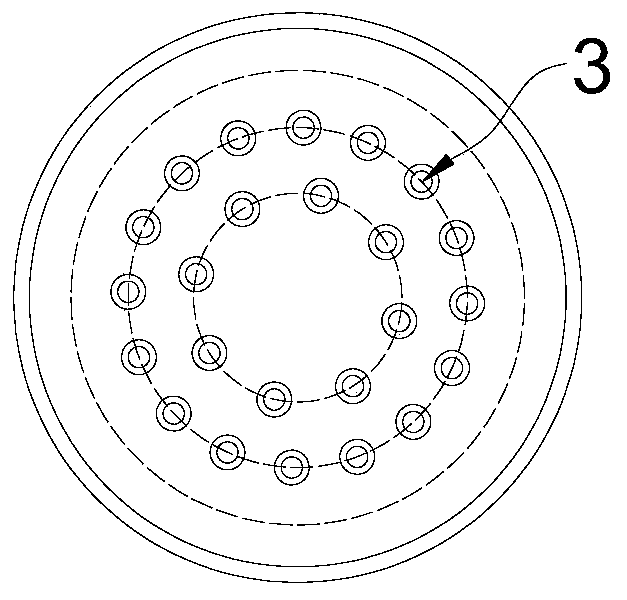

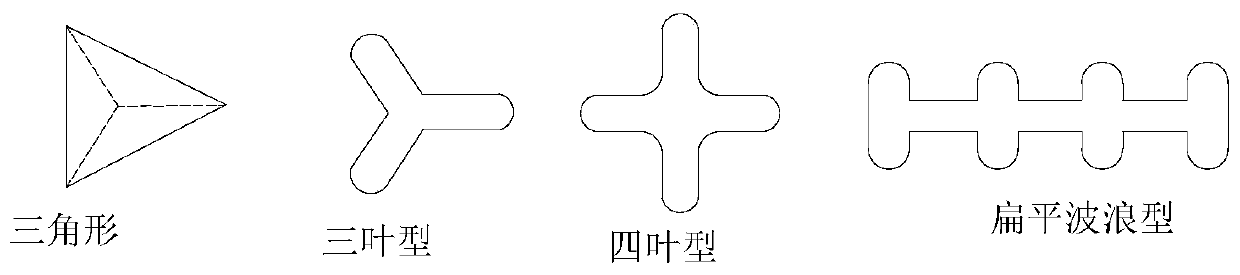

[0044] In the preparation method of the melt-spun special-shaped polyvinyl alcohol fiber in this embodiment, the special-shaped spinneret microholes of the spinneret adopt a four-lobed shape, and the degree of special shape is 50%. It includes the following steps:

[0045] (1) The chemically modified polyvinyl alcohol powder is melt-spun on extrusion-spinning equipment, and after melt-extruding, filtering and metering, it is sprayed from the special-shaped spinning micropores, and the melt is The special-shaped polyvinyl alcohol primary fiber is prepared by blowing and cooling on the side of the thin stream; wherein, the step of chemically modifying the polyvinyl alcohol powder includes: copolymerizing polyvinyl monomers on the polyvinyl alcohol molecular chain.

[0046] Among them, the spinning temperature is 165°C; the spinning shear rate is 10000s -1 ; Spinning shear viscosity is 300Pa.s; spinning pressure is 25MPa; spinning volume flow rate is 300mm 3 / s; spinneret draw ...

Embodiment 2

[0050] In the preparation method of the melt-spun special-shaped polyvinyl alcohol fiber in this embodiment, the special-shaped spinneret microholes of the spinneret are flat and wavy, and the degree of special shape is 90%. It includes the following steps:

[0051] (1) The chemically modified polyvinyl alcohol powder is melt-spun on extrusion-spinning equipment, and after melt-extruding, filtering and metering, it is sprayed from the special-shaped spinning micropores, and the melt is The special-shaped polyvinyl alcohol primary fiber is prepared by blowing and cooling on the side of the thin stream; wherein, the step of chemically modifying the polyvinyl alcohol powder includes: grafting n-butyl boric acid on the polyvinyl alcohol molecular chain.

[0052] Among them, the spinning temperature is 180°C; the spinning shear rate is 6000s -1 ; Spinning shear viscosity is 200Pa.s; spinning pressure is 30MPa; spinning volume flow rate is 250mm 3 / s; the draw ratio of the spinner...

Embodiment 3

[0056] In the preparation method of the melt-spun special-shaped polyvinyl alcohol fiber in this embodiment, the special-shaped spinneret microholes of the spinneret adopt a trilobal shape, and the degree of special shape is 75%. It includes the following steps:

[0057] (1) The physically modified polyvinyl alcohol powder is melt-spun on extrusion-spinning equipment, and after melt-extruded, filtered and metered, it is ejected from the micro-pores of the special-shaped spinneret, and the melt is Cooling with side air blowing in a thin stream to prepare shaped polyvinyl alcohol primary fibers; wherein, the step of physically modifying polyvinyl alcohol powder includes: mixing and compounding glycerin, starch and polyvinyl alcohol according to the mass ratio of 10:30:60 to obtain modified polyvinyl alcohol fibers. Non-toxic polyvinyl alcohol powder.

[0058] Among them, the spinning temperature is 175°C; the spinning shear rate is 2000s -1 ; Spinning shear viscosity is 150Pa....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Irregularity | aaaaa | aaaaa |

| Irregularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com