Organosilicon compound and manufacturing method thereof, and curable composition

An organosilicon compound and a manufacturing method technology, applied in chemical instruments and methods, other household appliances, electronic equipment, etc., can solve the problem of insufficient adhesion between resin materials and copper foil, and achieve the effect of excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

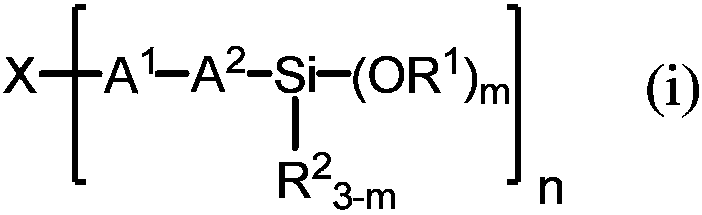

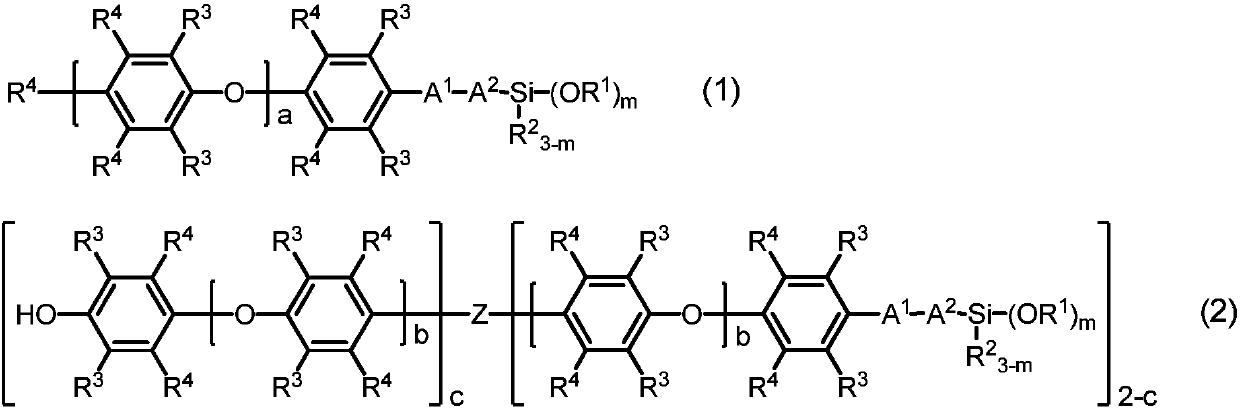

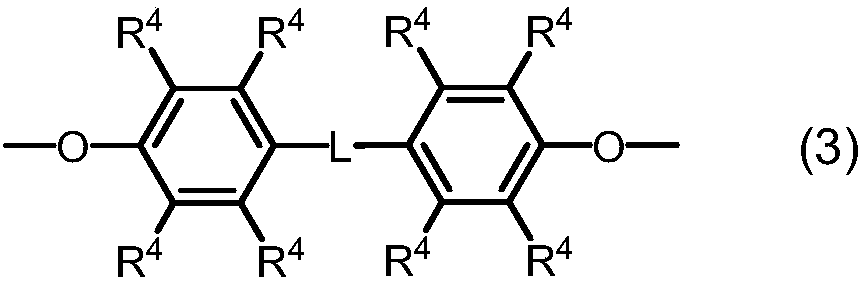

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0173] [Example 1-1] Synthesis of organosilicon compound 1

[0174] Into a 200 mL detachable flask equipped with a stirrer, a reflux condenser, a dropping funnel, and a thermometer, 40 g of PPO (trademark) SA120-100 (manufactured by SABIC Innovative Plastics), 110 g of toluene, and 0.05 g, heated to 80°C. 7.6 g of 3-isocyanatopropyl trimethoxysilane was added dropwise thereto, and it heated and stirred at 80 degreeC for 2 hours. It was confirmed by IR measurement that the absorption peak derived from the isocyanate group of the raw material completely disappeared, and an absorption peak derived from a urethane bond was generated instead, and the reaction was considered to be complete.

[0175] The obtained reaction product is a brown transparent liquid with a weight average molecular weight of 6,700 and a viscosity of 23mm 2 / s, and the non-volatile content was 34% by mass.

Embodiment 1-2

[0176] [Example 1-2] Synthesis of organosilicon compound 2

[0177] It synthesized by the same procedure as Example 1-1 except having changed the quantity of 3-isocyanatopropyl triethoxysilane into 9.2 g.

[0178] The obtained reaction product is a brown transparent liquid with a weight average molecular weight of 6,800 and a viscosity of 30 mm 2 / s, and the non-volatile content was 30% by mass.

Embodiment 1-3

[0179] [Example 1-3] Synthesis of organosilicon compound 3

[0180] Except having changed the quantity of toluene into 120g and the quantity of 3-isocyanatopropyl trimethoxysilane into 11.1g, it synthesize|combined by the procedure similar to Example 1-1.

[0181] The obtained reaction product is a brown transparent liquid with a weight average molecular weight of 5,300 and a viscosity of 21 mm 2 / s, and the non-volatile content was 29% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com