Stretched multilayer thermoplastic resin film

A thermoplastic resin and stretch film technology, applied in the direction of synthetic resin layered products, laminated, layered products, etc., can solve the problems of easy increase in birefringence, poor appearance, insufficient continuous productivity, etc., and achieve excellent continuous productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] Hereinafter, the present invention will be specifically described using examples. However, the present invention is not limited by these Examples and Comparative Examples. The thermoplastic resin laminated stretched films obtained in Examples and Comparative Examples were evaluated as follows.

[0082]

[0083] For the thermoplastic resins obtained in the following synthesis examples, the hydrogenation rate was determined from the decrease rate of the absorption at 260 nm in the UV spectrometry before and after the hydrogenation reaction. From the absorbance A1 of the resin concentration C1 before the hydrogenation reaction, and the absorbance A2 of the resin concentration C2 after the hydrogenation reaction, it was calculated by the following formula.

[0084] Hydrogenation rate = 100×[1-(A2×C1) / (A1×C2)]

[0085]

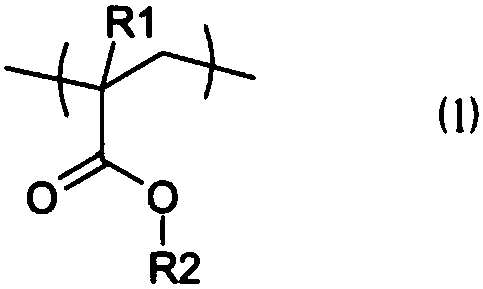

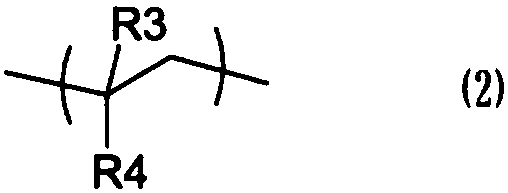

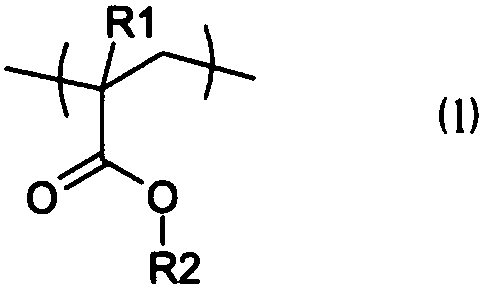

[0086] For the thermoplastic resins obtained in the following synthesis examples, the dielectric polarization differences of the bonding units of the ...

Synthetic example 1

[0106] Synthesis Example 1 [Manufacture of Vinyl Copolymer Resin (B1)]

[0107] 77.0 mol% of purified methyl methacrylate (manufactured by Mitsubishi Gas Chemical Co., Ltd.), 23.0 mol% of purified styrene (manufactured by Wako Pure Chemical Industries, Ltd.), and 2-ethyl peroxide as a polymerization initiator tert-Amyl hexanoate (manufactured by Arkema Jifu Co., Ltd., trade name: LUPEROX 575) 0.002 mol% of the monomer composition was continuously supplied to a 10L complete mixing tank with a screw blade at 1 kg / h, with an average residence time of 2.5 Continuous polymerization was carried out at a polymerization temperature of 150°C. It was discharged continuously from the bottom so that the liquid level of the polymerization tank was constant, and introduced into a solvent removal device to obtain a pellet-like vinyl copolymer resin (B1').

[0108] The obtained vinyl copolymer resin (B1') was dissolved in methyl isobutyrate (manufactured by Kanto Chemical Co., Ltd.) to prepa...

Synthetic example 2

[0109] Synthesis Example 2 [Manufacture of Vinyl Copolymer Resin (B2)]

[0110] The usage-amount of methyl methacrylate used in Synthesis Example 1 was set to 62.0 mol%, and the usage-amount of styrene was set to 38.0 mol%, except that, it was carried out in the same manner as in Synthesis Example 1 to obtain a vinyl copolymer resin (B2). use 1 As a result of H-NMR measurement, the ratio of the methyl methacrylate structural unit was 60 mol%, and as a result of absorbance measurement at a wavelength of 260 nm, the hydrogenation reaction rate of the benzene ring site was 99%. The obtained vinyl copolymer resin (B2) had a glass transition temperature of 120°C and a saturated water absorption of 0.6 wt%. In addition, the intrinsic birefringence of the obtained vinyl copolymer resin (B2) was +0.0021.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| photoelasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com