A method for preparing calcium silicate hydrate and magnetic hydrotalcite from industrial waste

A technology of magnetic hydrotalcite and hydrated calcium silicate, which is applied in chemical instruments and methods, hydrotalcite, solid waste removal, etc., can solve the problems of low added value, high cost, and low cost, and achieve high energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

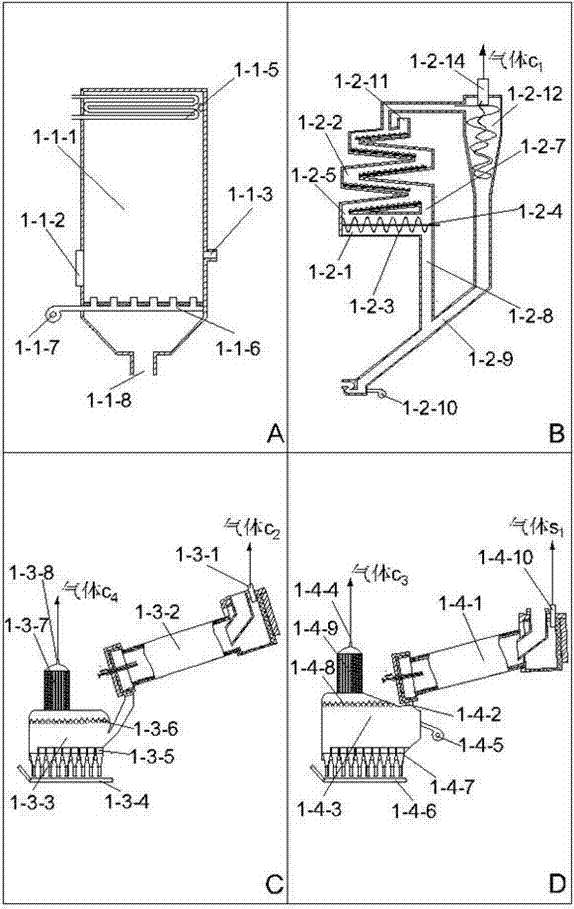

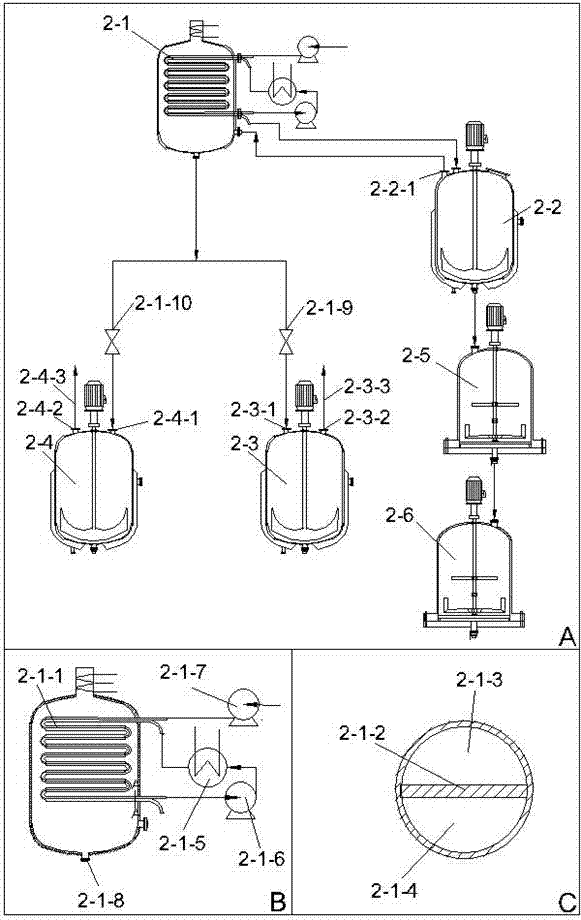

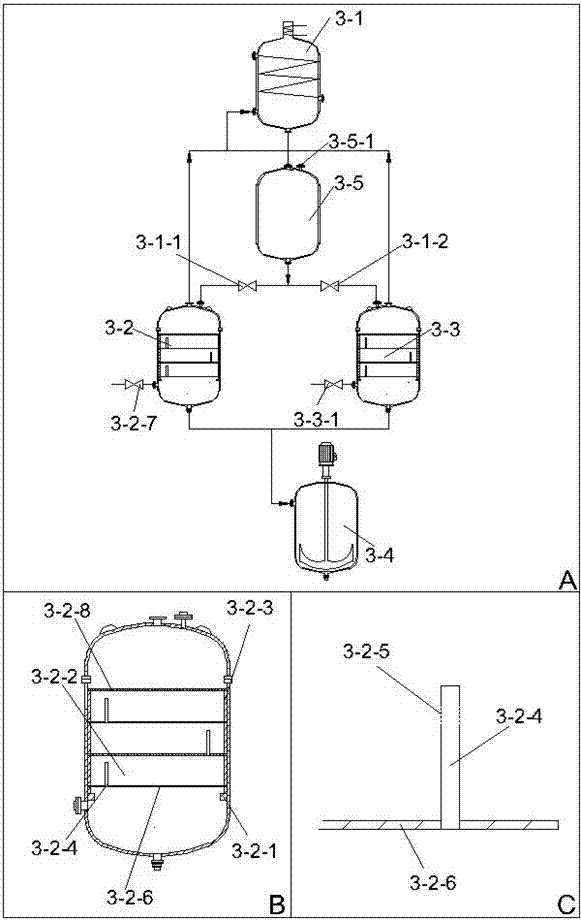

[0076] A method for preparing calcium silicate hydrate and magnetic hydrotalcite using industrial waste, the method is divided into five steps: step 1 is burning and activating white mud and high-sulfur coal; step 2 is distillation; step 3 is distillation extraction; step 4 is extraction and separation; Step 5 is synthesis and "three wastes" treatment;

[0077] Step 1: Combustion activation of white mud and high-sulfur coal

[0078] White mud and high-sulfur coal are mixed according to the ratio of calcium atom to aluminum atom in the ratio of 0.8:1-1.5:1, and sent to the fluidized combustion chamber (1-1-1) for combustion, and the soot produced during the combustion process enters the The lime mud gas-solid mixer (1-2-1) is mixed with the lime mud and returned to the fluidized combustion chamber (1-1-1) through the second fan (1-2-10); The ratio of calcium-aluminum substances in high-sulfur coal to white mud is 2:1-3:1.

[0079] The ash generated by combustion enters the se...

Embodiment 2

[0100] This embodiment is basically the same as the method for preparing calcium silicate hydrate and magnetic hydrotalcite by using industrial waste described in Example 1, the difference is that in step 1, white mud and high-sulfur coal are based on the amount of calcium atoms and aluminum atoms The ratio of the amount is 0.8:1-1.5:1 mixing ratio, preferably 1.4:1.

[0101] Calcium atoms and aluminum atoms are 1.4:1, reducing the amount of lime mud added through the mixer, which is conducive to keeping the temperature in the furnace stable.

Embodiment 3

[0103] This example is basically the same as the method described in Example 1 for preparing calcium silicate hydrate and magnetic hydrotalcite from industrial waste, except that in step 1, during the stable combustion process, high-sulfur coal and white mud are maintained. The ratio of the amount of medium-calcium-aluminum substances is 2:1-3:1; preferably 2.2:1.

[0104] The preferred ratio is 2.2:1, which can reduce the energy consumption during lime mud treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com