Preparation method of magnetic induction hyperthermia embolism microspheres

A technology of magnetic induction hyperthermia and embolization microspheres, which is applied in the field of biological and medical micro-nano materials, can solve the problems of decreased embolization hyperthermia effect and easy metabolism of iodized oil, and achieves excellent heating performance, good biological safety and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1. Microwave-assisted high-temperature pyrolysis method prepares Fe 3 o 4 nanoparticles

[0036] 1mmol of iron acetylacetonate (Fe(acac) 3 ) into a mixed solvent system containing 8 mL oleylamine (OAm), 2 mL oleic acid (OA) and 6 mL octadecene (ODE). Under the radiation of the maximum microwave output power of 850W, the mixture was rapidly heated from room temperature to 200°C through a rapid heating program and kept for 10 min. Immediately afterwards, continue to heat up to 270°C within 5 minutes and maintain for 15 minutes. Finally, the temperature of the system was lowered to 70° C. within about 3 minutes, and the reaction was completed. After the above five steps, the obtained nanoparticles were repeatedly washed with a mixed solvent of ethanol and acetone to fully remove the residual solvent, and then placed in a vacuum drying oven for drying after magnetic separation.

[0037] figure 1 a is the transmission electron microscope image, the average s...

Embodiment 2

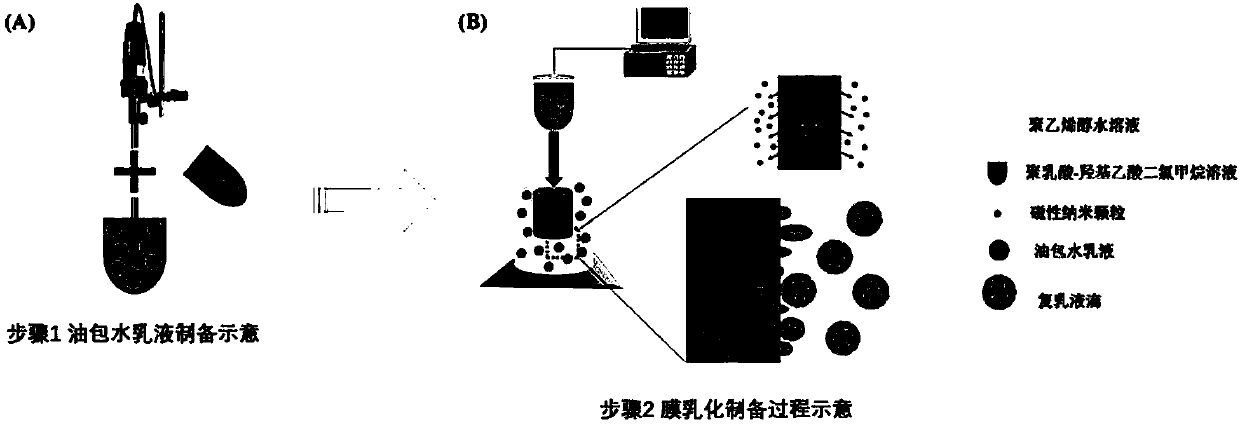

[0038] Example 2. Preparation of magnetic induction hyperthermia embolization microspheres with a size of 100-300 μm

[0039] The 20-50nm Fe prepared by microwave in embodiment 1 3 o 4 (Oil phase) Add 50 μL of surfactant Span 80 to 160 mg of granules, and mix evenly. Subsequently, 22 mL of a prepared 5% oil-soluble degradable high molecular polymer dichloromethane solution was quickly added, and 2 mL of the inner aqueous phase containing 2% PVA was fully stirred by dropwise addition. The W / O colostrum was prepared by high shear emulsification at 20k rpm / min, 9°C constant temperature environment. After the colostrum is obtained, quickly place it in a membrane emulsification syringe pump and add 200 mL of 4% PVA aqueous solution as the external water phase to start emulsification through the membrane. Microspheres with a size of 100-300 μm can be obtained by setting and adjusting the stirring speed between 1200-800 rpm / min and curing in a constant temperature environment of 9...

Embodiment 3

[0041] Example 3. Preparation of biodegradable magnetic induction hyperthermia embolization microspheres with a size of 400-600 μm

[0042] The 20-50nm Fe prepared by microwave in embodiment 1 3 o 4 (Oil phase) Add 100 μL of surfactant Span 80 to 180 mg of granules, and mix well. Subsequently, 18 mL of a prepared 8% oil-soluble degradable high molecular polymer dichloromethane solution was quickly added, and 2 mL of the inner aqueous phase containing 3% PVA was fully stirred by dropwise addition. The W / O colostrum was prepared by high shear emulsification at 22k rpm / min, 7°C constant temperature environment. After the colostrum is obtained, quickly place it in a membrane emulsification syringe pump and add 250 mL of 6% PVA aqueous solution as the external water phase to start emulsification through the membrane. Microspheres with a size of 400-600 μm can be obtained by setting and adjusting the stirring speed between 700-500 rpm / min and curing in a constant temperature envi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com