Porcelain tile with high polishing waste content and preparation method thereof

A polishing waste and high-dosage technology, applied in the field of architectural ceramics, to achieve efficient resource utilization, high utilization rate, and reduce raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

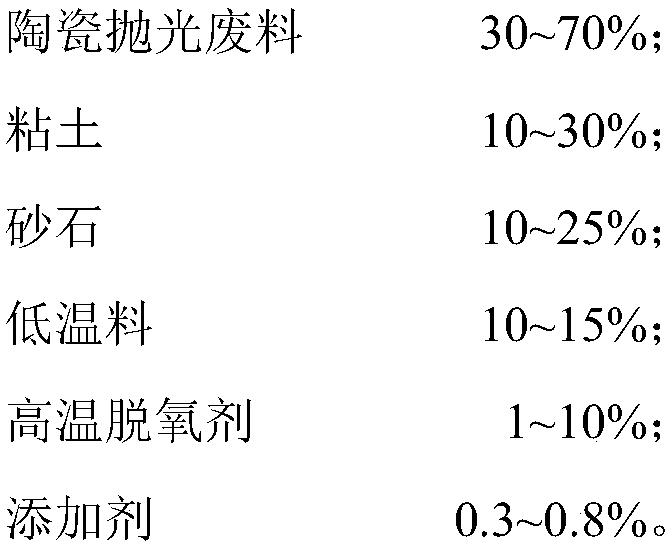

Method used

Image

Examples

Embodiment 1

[0016] A preparation method for porcelain tiles containing high-volume polishing waste, comprising the following process steps:

[0017] 1) Ingredients: by mass percentage, take by weight 5% kaolin, 5% black mud, 5% potassium sand, 8% aluminum potassium sand, 12% high aluminum potassium sodium sand, 3% calcite, 5% % talc, 7% nepheline, 44.5% ceramic polishing waste, 1% aluminum powder with a fineness of 325 mesh, 4% silicon aluminum alloy powder with a fineness of 600 mesh, and 0.5% sodium tripolyphosphate. material;

[0018] 2) Ball milling: adding the mixture and water into a ball mill for ball milling, with a solid content of 60%, to obtain a slurry, and the milling fineness is less than 0.3% on a 250-mesh sieve;

[0019] 3) Spray granulation: the slurry is prepared into green body powder with a moisture content of 8% by spray granulation;

[0020] 4) Stale: stale the green body powder for 10 days;

[0021] 5) Molding: Molding the stale green body powder according to the...

Embodiment 2

[0028] A preparation method for porcelain tiles containing high-volume polishing waste, comprising the following process steps:

[0029] 1) Ingredients: by mass percentage, weigh 3% of bentonite, 27% of black mud, 4% of sodium sand, 6% of high alumina potassium sand, 12% of dolomite, 6% of talc, 7% of Nepheline, 34.2% ceramic polishing waste, 4% silicon-aluminum alloy powder with a fineness of 600 mesh, 3% silicon-aluminum-barium alloy powder with a fineness of 1000 mesh, 3% ferrosilicon alloy with a fineness of 2000 mesh, 0.8% carboxymethyl Sodium cellulose, mixed to obtain a mixture;

[0030] 2) Ball milling: adding the mixed material and water into a ball mill for ball milling, with a solid content of 65%, to obtain a slurry, and the milling fineness is less than 0.3% on a 250-mesh sieve;

[0031] 3) Spray granulation: the slurry is prepared into green body powder with a water content of 5% by spray granulation;

[0032] 4) Stale: stale the green body powder for 7 days; ...

Embodiment 3

[0040] A preparation method for porcelain tiles containing high-volume polishing waste, comprising the following process steps:

[0041] 1) Ingredients: by mass percentage, weigh 3% of illite, 3% of bentonite, 4% of black mud, 5% of high alumina potash sand, 5% of potash sand, 2% of calcite, 8% of Nepheline, 70% ceramic polishing waste, 1% fineness of 2500 mesh silicon manganese aluminum calcium iron alloy powder, 0.3% sodium polyacrylate, mixed to obtain a mixture;

[0042] 2) Ball milling: adding the mixture and water into a ball mill for ball milling, with a solid content of 70%, to obtain a slurry, and the milling fineness is less than 0.3% on a 250-mesh sieve;

[0043] 3) Spray granulation: the slurry is prepared into green body powder with a water content of 7% by spray granulation;

[0044] 4) Stale: stale the green body powder for 5 days;

[0045] 5) Molding: Molding the stale green body powder according to the normal one-time molding method to obtain bricks;

[0046]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com