Catalyst for decomposing ozone, and preparation method of catalyst

A catalyst, ozone technology, applied in separation methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of catalyst carrier consumption, low life, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] Aiming at the problem that the activity of the current ozone decomposition reaction catalyst is not high enough, the present invention provides a composite material catalyst with high catalytic activity at room temperature, and the preparation method is simple and convenient for industrial production. The object of the present invention can be achieved through the following technical solutions.

[0015] The application provides a catalyst for decomposing ozone, comprising:

[0016] diatomaceous earth; and

[0017] Fe-doped manganese oxide supported on diatomaceous earth;

[0018] The mass ratio of the Mn element in the manganese oxide to the total mass of the catalyst is 2-10%.

[0019] In some embodiments, the mass ratio of the Mn element in the Fe-doped manganese oxide in the catalyst to the total mass of the catalyst is greater than 2.2% or greater than 2.4%, and less than 8% or less than 6%, such as 2.5%, 3% , 4%, 5%, 6%, 7% or 8%.

[0020] In some embodiments, ...

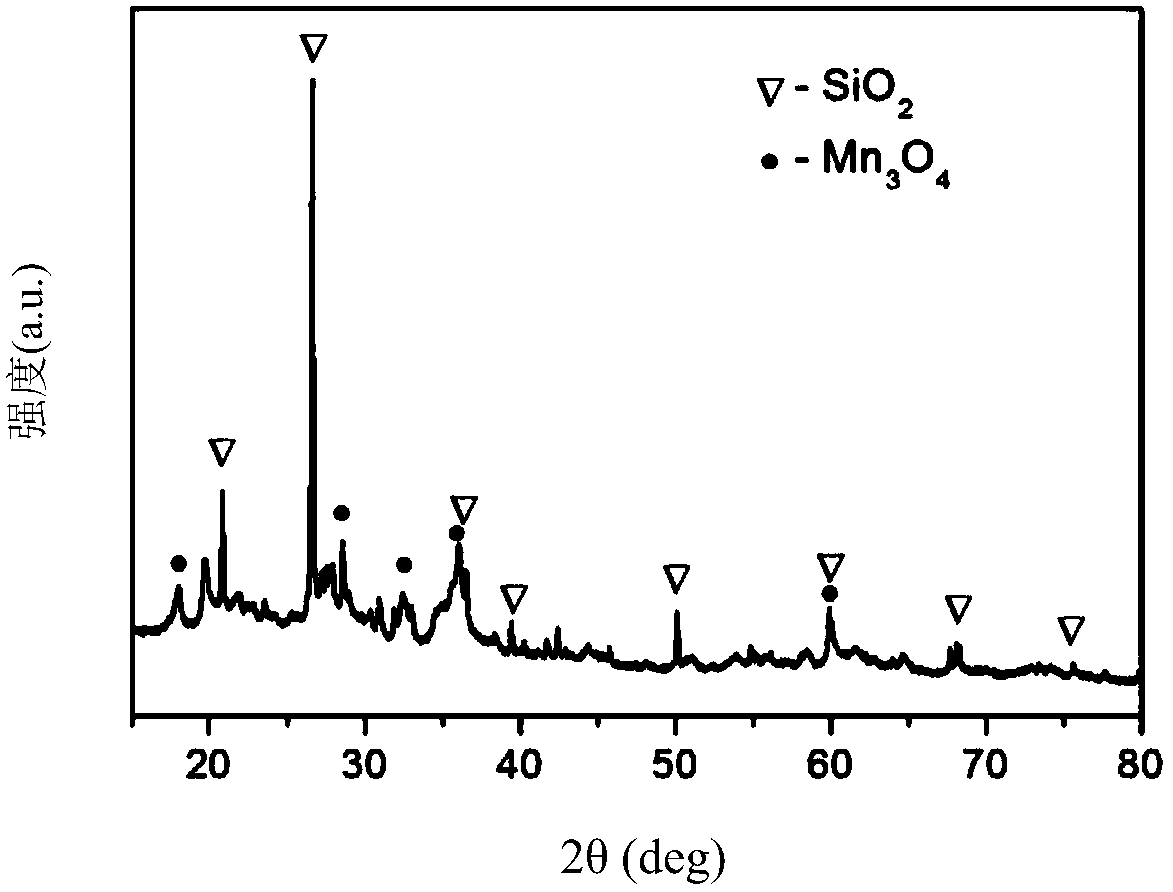

Embodiment 1

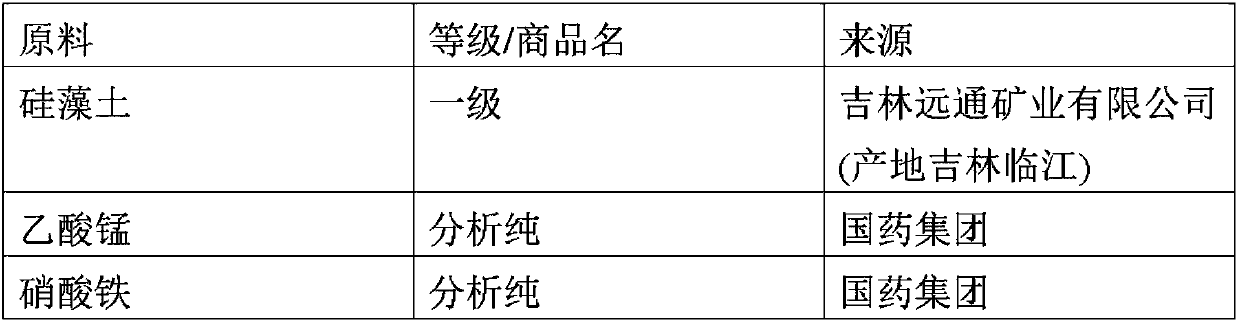

[0050] A diatomite-supported iron-doped manganese oxide composite material for catalyzing ozonolysis, the preparation process of which includes two simple processes of impregnation and calcination. First, prepare 200 ml of a mixed solution with manganese acetate and ferric nitrate concentration of 20% and 1.5%, add 10g of diatomaceous earth, stir for 30min, filter, and treat the filtered solid in a drying box at 80°C for 6 hours to dry Then, it was calcined at 350 °C for 50 min in an air atmosphere. like figure 1 X-ray powder diffraction analysis shows that the product is mainly composed of SiO formed by pretreatment of diatomite 2 and Mn 3 O 4 . Inductively coupled plasma spectroscopy analysis showed that the elemental mass contents of Mn and Fe in the composites were 4.9% and 1.46%, respectively. Using the prepared material as a catalyst, the air was passed through the ozone generator at 1 L / min at 25° C. and then flowed through the above material, and the ozone decompo...

Embodiment 2

[0052] Others are the same as in Example 1, except that the calcination temperature is lower, and the solid obtained by filtration is heat-treated at 200° C. in an air atmosphere for 60 minutes. No diffraction peaks of Mn crystalline oxides were observed by X-ray powder diffraction, indicating that Mn oxides in the catalyst product existed in an amorphous state, and the elemental mass contents of Mn and Fe were 5.1% and 1.49%, respectively. Using the prepared material as a catalyst, the air was passed through an ozone generator at 1 L / min at a temperature of 25° C. and then flowed through the above material, and the ozone decomposition rate was 74%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com