Catalyst for decomposing ozone and preparation method thereof

A catalyst and ozone technology, applied in the direction of separation methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high cost, consumption of catalyst carrier and low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] Aiming at the problem that the activity of the current catalyst for ozonolysis reaction is not high enough, the invention provides a composite material catalyst with high catalytic activity at room temperature, the preparation method of which is simple and convenient, and is beneficial to industrial production. The purpose of the present invention can be achieved through the following technical solutions.

[0015] The application provides a catalyst for decomposing ozone, comprising:

[0016] diatomaceous earth; and

[0017] Fe-doped manganese oxide loaded on diatomaceous earth;

[0018] Wherein the mass ratio of the Mn element in the manganese oxide to the total mass of the catalyst is 2-10%.

[0019] In some embodiments, the mass ratio of the Mn element in the Fe-doped manganese oxide in the catalyst to the total mass of the catalyst is greater than 2.2% or greater than 2.4%, and less than 8% or less than 6%, for example, it can be 2.5%, 3% , 4%, 5%, 6%, 7% or 8%. ...

Embodiment 1

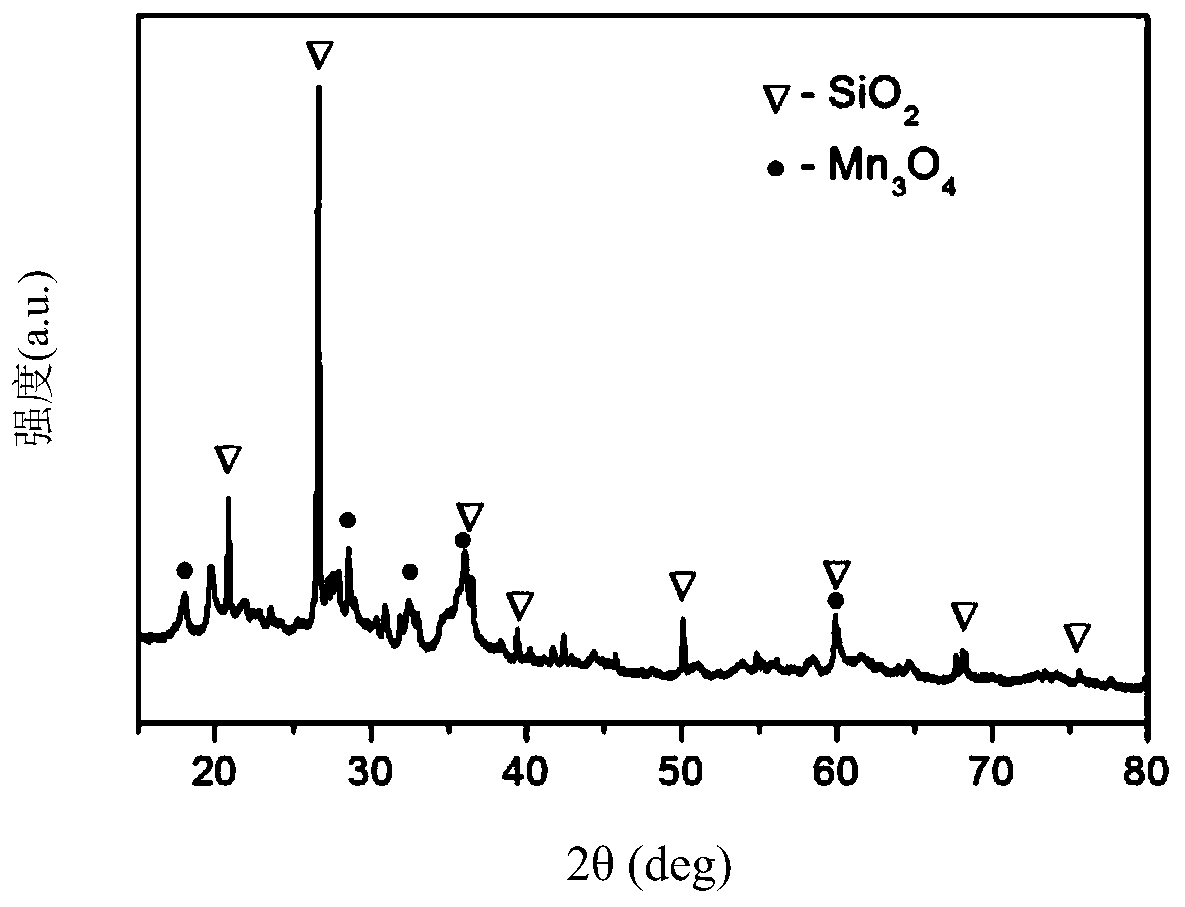

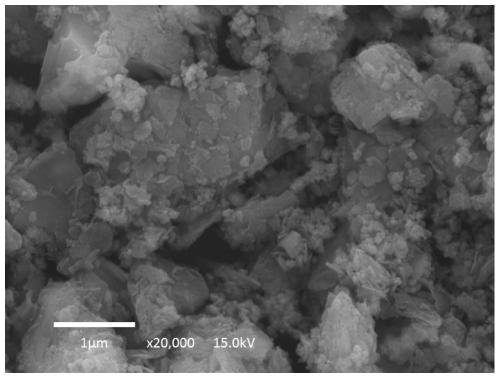

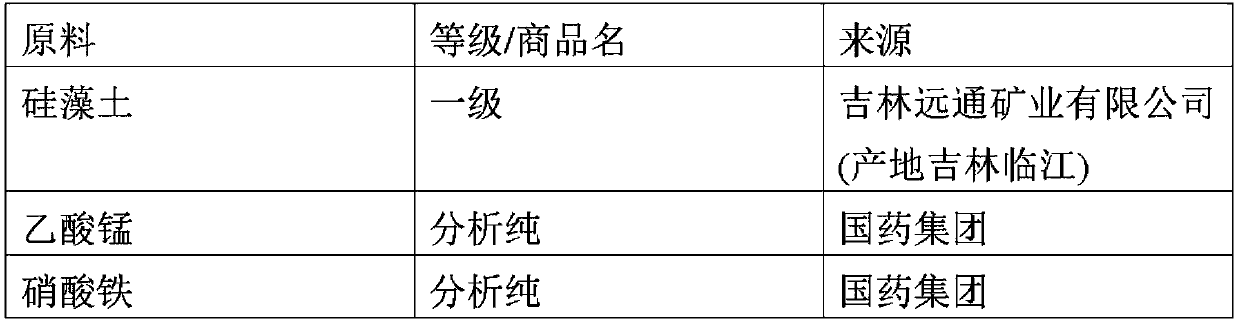

[0050] A manganese oxide composite material loaded with diatomite and doped with iron for catalyzing ozonolysis reaction, the preparation process includes two simple processes of impregnation and calcination. First prepare 200ml of mixed solutions with manganese acetate and ferric nitrate mass fraction concentrations of 20% and 1.5% respectively, add 10g of diatomaceous earth, stir for 30min and then filter, and process the filtered solid in an oven at 80°C for 6 hours to dry Then calcined at 350°C for 50min in an air atmosphere. Such as figure 1 As shown, X-ray powder diffraction analysis shows that the product composition is mainly SiO produced by diatomite pretreatment. 2 and Mn 3 o 4 . Inductively coupled plasma spectroscopic analysis showed that the elemental mass content of Mn and Fe in the composite was 4.9% and 1.46%, respectively. Using the prepared material as a catalyst, the air was passed through the ozone generator at 1 L / min at 25° C. and then flowed through...

Embodiment 2

[0052] Others are the same as in Example 1, except that the calcination temperature is lower, and the filtered solid is heat-treated for 60 minutes at 200° C. in an air atmosphere. X-ray powder diffraction did not observe the diffraction peaks of crystalline oxides of Mn, indicating that the oxides of Mn existed in an amorphous state in the catalyst product, and the mass contents of Mn and Fe were 5.1% and 1.49%, respectively. Using the prepared material as a catalyst, the air was passed through the ozone generator at 1 L / min at a temperature of 25° C. and then flowed through the material, and the ozone decomposition rate was 74%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com