A low-density high-manganese steel with high strength and plasticity

A technology of low-density steel and high-strength plastic product, which is applied in the direction of improving process efficiency, can solve problems such as unsatisfactory requirements, and achieve the effects of reducing cooling intensity, preventing lamellar tearing, and increasing nucleation cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

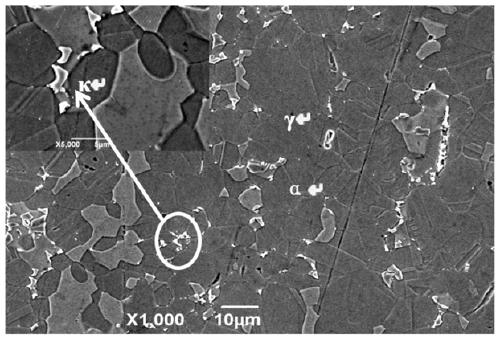

Image

Examples

Embodiment 1

[0039] A low-density high-manganese steel with high strength and plastic product in this embodiment, the chemical composition mass percentage of the low-density steel is: Mn: 19.4%, Al: 9.82%, C: 0.99%, P: 0.003%, S: 0.003 %, the rest are Fe and other unavoidable impurities, and the sum of the mass percentages of Mn and Al in the low-density steel>28%, which is 29.22% in this embodiment; and the mass percentage of Mn in the low-density steel is 19.40~20% %, the mass ratio of Mn to Al is 1.8 to 2.0, the mass percentage of Mn in this embodiment is 19.4%, and the mass ratio of Mn to Al is 1.98; in addition, it is worth noting that Al and C The mass ratio is 9.5-10.5, and it is 9.9 in this embodiment. The production steps are as follows:

[0040] Step (1) smelting: use low-carbon Mn-Fe as the matrix, add Al-Fe alloy and carbon powder, smelt through the vacuum induction melting furnace according to the required ratio, and pass argon gas into the furnace during the smelting process...

Embodiment 2

[0048] A low-density high-manganese steel with high strength and plastic product in this embodiment, the chemical composition mass percentage of the low-density steel is: Mn: 19.00%, Al: 9.80%, C: 0.98%, P: 0.003%, S: 0.003 %, the rest are Fe and other unavoidable impurities, and the ratio of raw materials and the preparation method are basically the same as in Example 1. Then the tensile strength, elongation after fracture and strong-plastic product of the low-density steel were tested, and the test results were recorded in Table 1.

Embodiment 3

[0050] A low-density high-manganese steel with high strength and plastic product in this embodiment, the chemical composition mass percentage of the low-density steel is: Mn: 19.8%, Al: 9.97%, C: 1%, P: 0.003%, S: 0.003 %, the rest are Fe and other unavoidable impurities, and the ratio of raw materials and the preparation method are basically the same as in Example 1. Then the tensile strength, elongation after fracture and strong-plastic product of the low-density steel were tested, and the test results were recorded in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com