Valve cam provided with cosine-constant speed type buffer section and used for internal combustion machine and lift curve determination method of valve cam

A valve cam and constant velocity curve technology, applied in valve details, valve drive devices, etc., can solve the problems of high movement speed and poor stability at the connection of the working section, and achieve the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

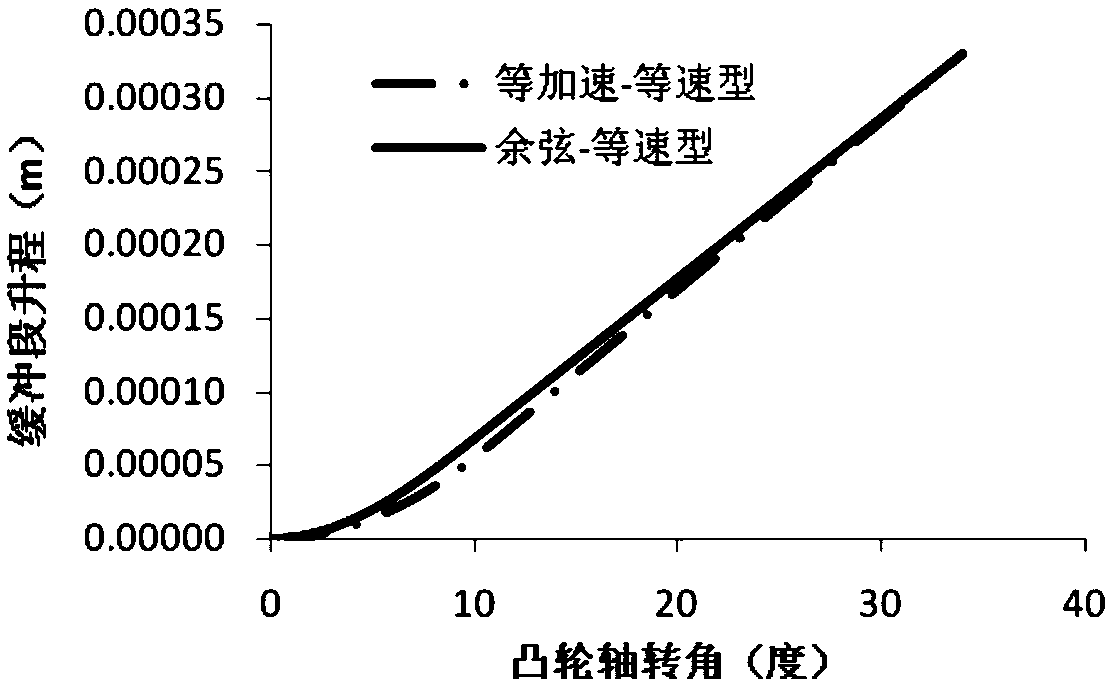

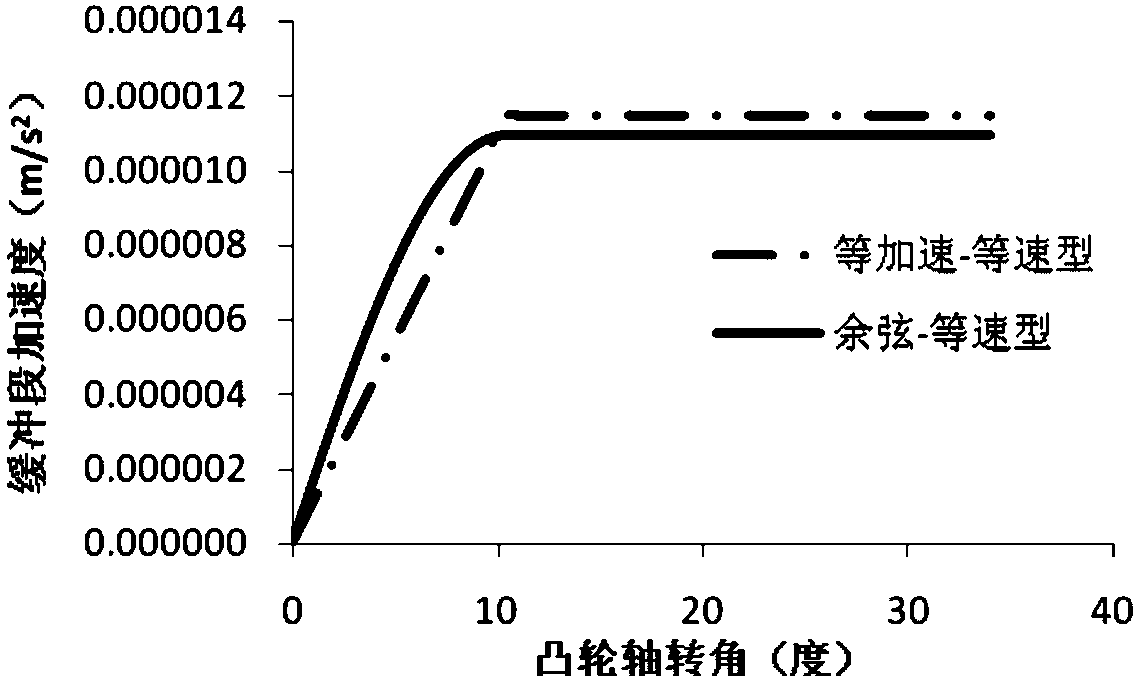

[0041] The present invention is described in more detail below in conjunction with accompanying drawing example:

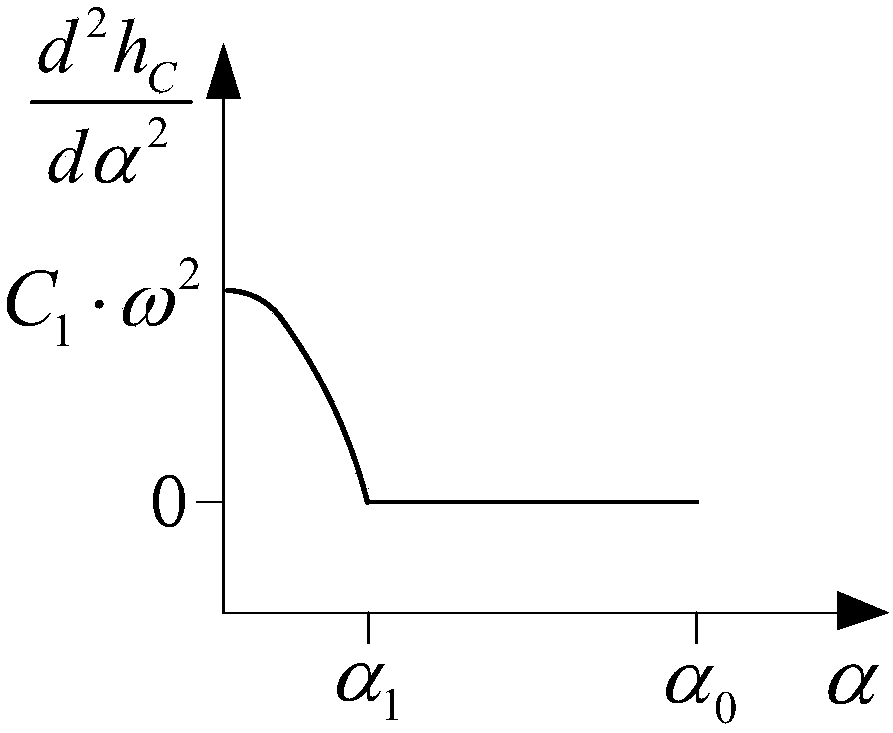

[0042] combine Figure 1-5 , the lift curve h of the cosine-constant velocity type buffer section of the present invention C (α) consists of two sections, and its expression can be written as:

[0043]

[0044] The corresponding speed, acceleration and jerk curve expressions are:

[0045]

[0046]

[0047]

[0048] In the formula, α 1 is the wrapping angle of the cosine segment, α 0 is the wrapping angle of the buffer section, α 1 、C 1 ,E 0 ,E 1 are undetermined constants,

[0049] The size can be determined by the boundary conditions and α=α 1 The continuity condition is obtained. Specifically follow the steps below:

[0050] Step 1: Given the lift h of the buffer section 0 , buffer section wrap angle α 0 And cosine section wrap angle factor G.

[0051] Step 2: Determine the wrap angle of the cosine segment according to the wrap angle co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com