Needle-free electrostatic spinning assembly based on fractal structures

A fractal structure, electrospinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

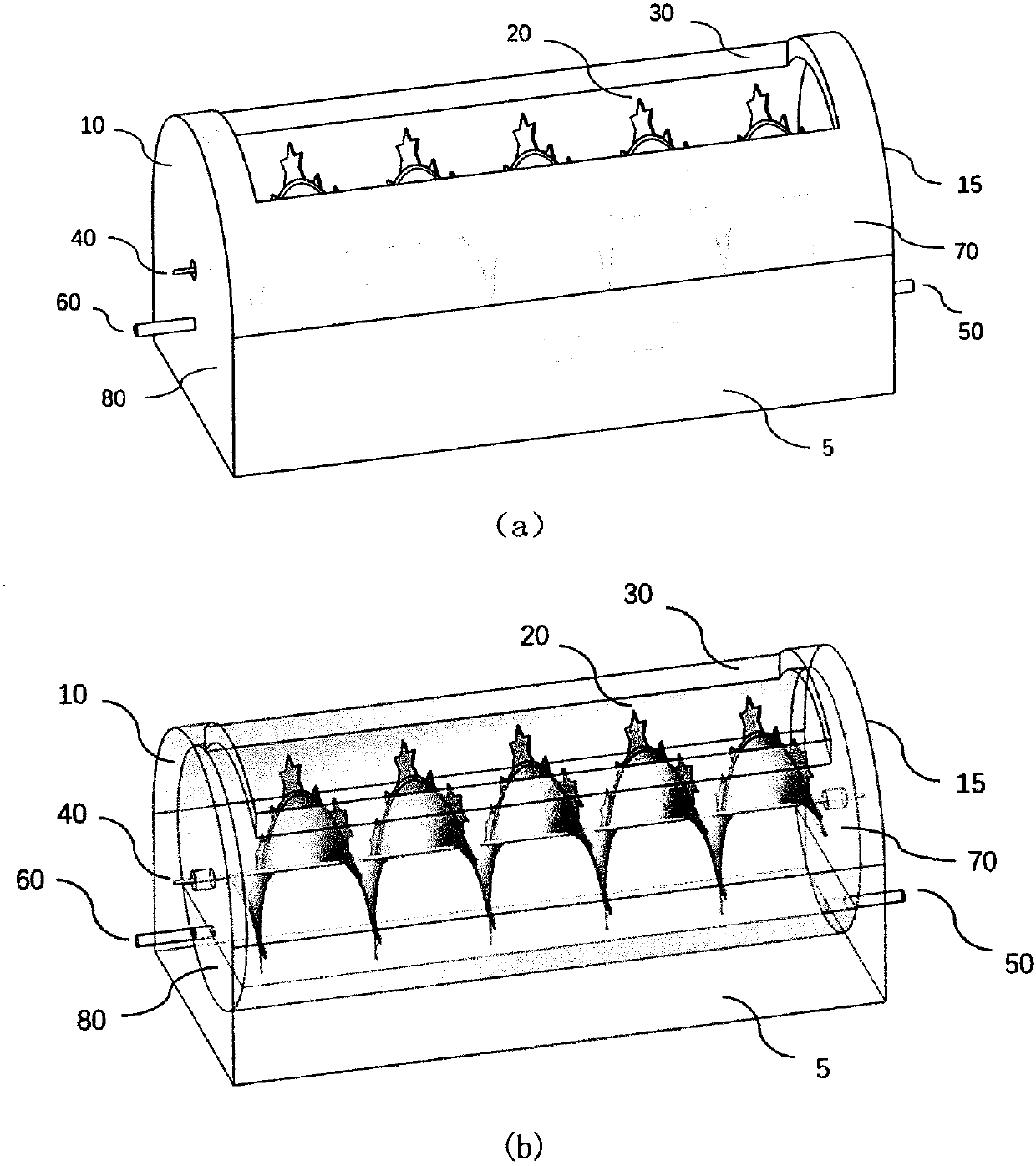

Embodiment 1

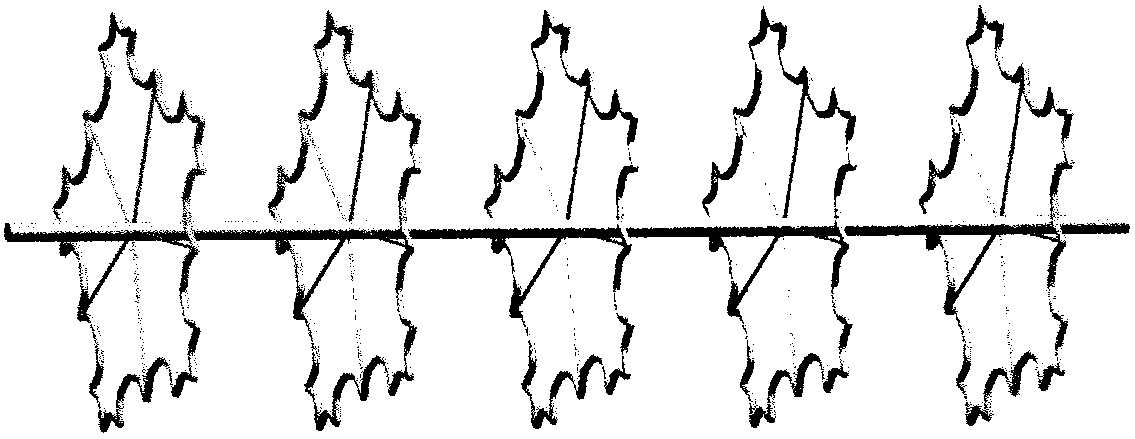

[0037] Needle-free multi-jet electrospinning is carried out using a spinning head composed of five broken-line von Koch fractal structures, and each fractal structure spinning unit is connected to the central axis by five spokes passing through the center (see Figure 2~3 ), the broken line of the fractal structural unit is made of brass wire with a diameter of 3mm. The prepared spinning solution is injected into the cylindrical liquid storage tank in the spinning box body through the liquid supply pump (conventional technology), the motor speed is set to 10rev / min, 20kV DC high voltage is introduced into the spinning solution, and the adjustment The receiving distance is 18cm. Start the motor, and when the electrospinning process is stable, set the receiving time to 10 minutes. The obtained nanofibers have an average diameter of 279.58 nm and a CV value of 8.86%. Figure 10 It is the SEM image of nanofibers with a mass fraction of 13% PVDF-HFP.

Embodiment 2

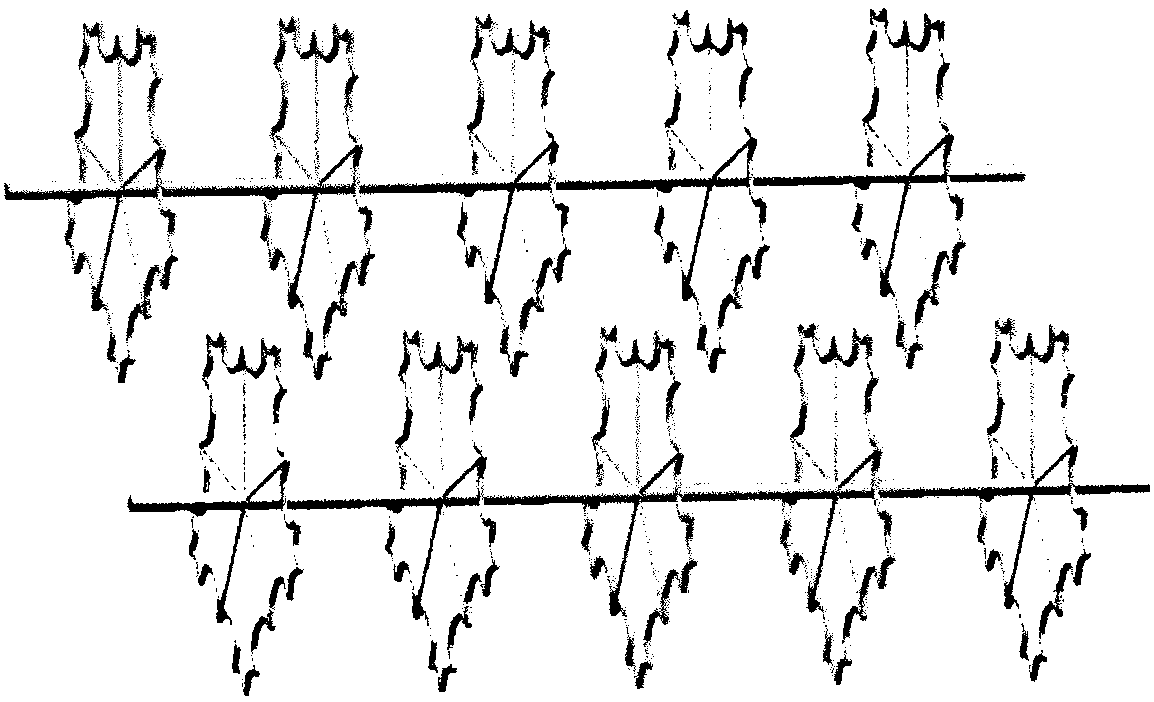

[0039] Needle-free multi-jet electrospinning is carried out using a spinning head composed of five torus-shaped von Koch fractal structures, and each fractal structure spinning unit is connected to the central axis by four spokes passing through the center (see Figure 4~5 ), the torus structure of the fractal structural unit is made of aluminum sheet with a thickness of 5 mm. The prepared spinning solution is injected into the cylindrical liquid storage tank in the spinning box through the liquid supply pump (conventional technology), the motor speed is set to 20rev / min, 22kV DC high voltage is introduced into the spinning solution, and the adjustment The receiving distance is 20cm. Start the motor, and when the electrospinning process is stable, set the receiving time to 10 minutes. The obtained nanofibers have an average diameter of 276.93 nm and a CV value of 13.40%. Figure 11 It is the SEM image of nanofibers with a mass fraction of 13% PVDF-HFP.

Embodiment 3

[0041] A spinning head composed of five planar von Koch fractal structures is used for needle-free multi-jet electrospinning, and each fractal structure spinning unit is connected in series by a central shaft passing through the center (see Figure 6~7 ), the torus structure of the fractal structural unit is made of a stainless steel sheet with a thickness of 4 mm. The prepared spinning solution is injected into the cylindrical liquid storage tank in the spinning box body through the liquid supply pump (conventional technology), the motor speed is set to 30rev / min, 22kV DC high voltage is introduced into the spinning solution, and the adjustment The receiving distance is 19cm. Start the motor, and when the electrospinning process is stable, set the receiving time to 10 minutes. The obtained nanofibers have an average diameter of 308.92 nm and a CV value of 10.04%. Figure 12 It is the SEM image of nanofibers with a mass fraction of 13% PVDF-HFP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com