A kind of preparation transparent bi 2 se 3 thin film method

A thin-film and transparent technology, which is applied in the field of preparing transparent Bi2Se3 thin films, can solve the problems of low deposition rate, high energy consumption, and flammable residual gas, and achieve high magnetron sputtering efficiency, low preparation cost, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation of transparent Bi 2 Se 3 A thin film method comprising the steps of:

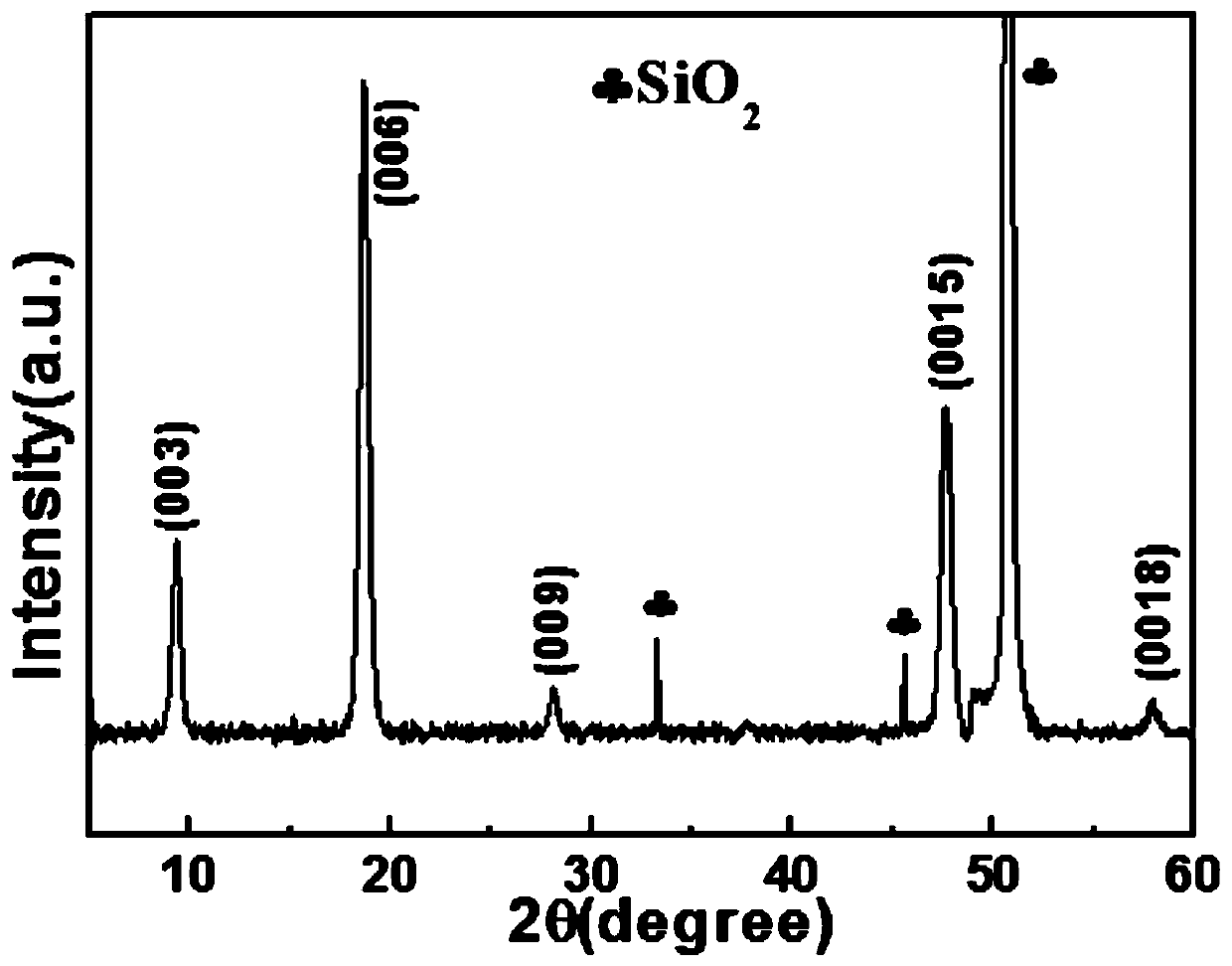

[0026] a. Sputtering deposition: select quartz (SiO 2 ) substrate or sapphire (Al 2 o 3 ) substrate as the substrate for magnetron sputtering, select Bi with a purity of 99.999% 2 Se 3 The material is used as the target material of magnetron sputtering, and a layer of Bi is deposited on the substrate by sputtering 2 Se 3 film;

[0027] The process conditions of sputtering deposition are: the distance from the target to the substrate is 7cm, and the air pressure in the vacuum chamber is less than 2×10 -4 Pa, and then feed argon with a purity of 99.995% as the working gas; the gas pressure during sputtering is 0.5 Pa, the substrate temperature is 330° C., the sputtering power is 70 W, and the sputtering time is 3 seconds.

[0028] b. Post-annealing treatment: deposit Bi with step a 2 Se 3 The substrate of the film and selenium balls with a particle size of 0.6mm-1.2mm are seal...

Embodiment 2

[0035] A preparation of transparent Bi 2 Se 3 A thin film method comprising the steps of:

[0036] a. Sputtering deposition: select sapphire (Al 2 o 3 ) substrate as the substrate for magnetron sputtering, Bi with a purity of 99.999% was selected 2 Se 3 The material is used as the target material of magnetron sputtering, and a layer of Bi is deposited on the substrate by sputtering 2 Se 3 film;

[0037] The process conditions of sputtering deposition are: the distance from the target to the substrate is 5cm, and the air pressure in the vacuum chamber is less than 2×10 -4 Pa, and then feed argon with a purity of 99.995% as the working gas; the gas pressure during sputtering is 0.45Pa, the substrate temperature is 350°C, the sputtering power is 60W, and the sputtering time is 5 seconds.

[0038] b. Post-annealing treatment: deposit Bi with step a 2 Se 3 The substrate of the film and the selenium balls with a particle size of 0.9 mm are sealed together with an air pressu...

Embodiment 3

[0045] A preparation of transparent Bi 2 Se 3 A thin film method comprising the steps of:

[0046] a. Sputtering deposition: select quartz (SiO 2 ) substrate as the substrate for magnetron sputtering, select Bi with a purity of 99.999% 2 Se 3 The material is used as the target material of magnetron sputtering, and a layer of Bi is deposited on the substrate by sputtering 2 Se 3 film;

[0047] The process conditions of sputtering deposition are: the distance from the target to the substrate is 6cm, and the air pressure in the vacuum chamber is less than 2×10 -4 Pa, and then feed argon with a purity of 99.995% as the working gas; the gas pressure during sputtering is 0.35Pa, the substrate temperature is 380°C, the sputtering power is 55W, and the sputtering time is 10 seconds.

[0048] b. Post-annealing treatment: deposit Bi with step a 2 Se 3 The substrate of the film and selenium balls with a particle size of 1.0 mm are sealed together with an air pressure of less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com