Method for preparing graphene nanowall on large scale

A graphene nano-wall and large-scale preparation technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of complex preparation conditions, difficult control, expensive instruments, etc., and achieve the effect of simple preparation process, low cost, and abundant surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

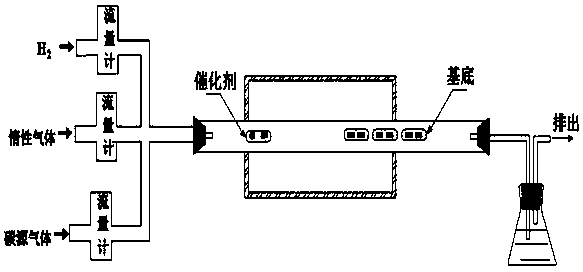

[0024] The specific steps of growing graphene nanowalls by thermal chemical vapor deposition are as follows:

[0025] a. Place the substrates for growing graphene nanowalls in acetone, 95% ethanol, and deionized water for 3 minutes, and then dry them with nitrogen;

[0026] b. Place the stainless steel wire mesh in step a in three quartz boats respectively. Wherein the quartz boat near the end of the gas outflow heating furnace was put into 0.02 g of nickel foam, and the last two quartz boats were put into carbon paper respectively. In addition, a quartz boat containing 0.05 g of catalyst ferrocene and 0.025 g of nickel foam was placed in the heating zone where the reaction gas first flowed into the quartz tube.

[0027] c. Under normal pressure, feed 30 sccm of argon and raise the furnace temperature to 1100° C. at a rate of 27° C. / min, adjust the argon to 15 sccm, and introduce 90 sccm of methane and 30 sccm of hydrogen. Move the quartz boat equipped with the catalyst to e...

Embodiment 2

[0029] The difference from Example 1 is that the quartz tube was wiped dry with cotton soaked in ethanol. Then carry out the reaction according to the relevant conditions in Example 1, and graphene nanowalls can also be obtained, but only locally distributed. The resulting graphene nanowall SEM image is as follows image 3 shown.

Embodiment 3

[0031] What is different from Example 1 is that it reacts with the same conditions of Example 1, and can also obtain graphene nanowalls, but grows out impurities such as carbon fibers at the same time, and the resulting SEM image is as follows Figure 4 , Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com