Method for modifying lithium nickel manganate by replacing Mn with doped P non-equivalently, and application of modified lithium nickel manganate

A lithium nickel manganese oxide, unequal technology, applied in the field of preparation of modified lithium nickel manganese oxide, can solve the problems of poor high-temperature cycle performance, poor cycle performance, and restrictions on wide application, and achieve high tap density and low cost , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0042] Add 0.08mol of citric acid to 100ml of deionized water, and after the citric acid is dissolved, add 0.043125mol of elemental manganese powder, 0.015mol of nickel acetate, 0.0315mol of lithium acetate and 0.0015mol of diammonium hydrogen phosphate; The solution was magnetically stirred at room temperature for 5 hours; the mixed solution was evaporated to dryness with magnetic stirring at a constant temperature of 80°C to obtain a precursor; the above precursor was pre-decomposed at 230°C for 4 hours, and the obtained pre-decomposed product was ground to obtain a ground product The grinding product is subjected to two-step heat treatment under air atmosphere conditions, and the two-step heat treatment conditions are temperature 650°C, time 10h and temperature 900°C, time 2h, and then cooling with the furnace to obtain high-performance P non-equal doping Lithium nickel manganese oxide lithium ion battery cathode material.

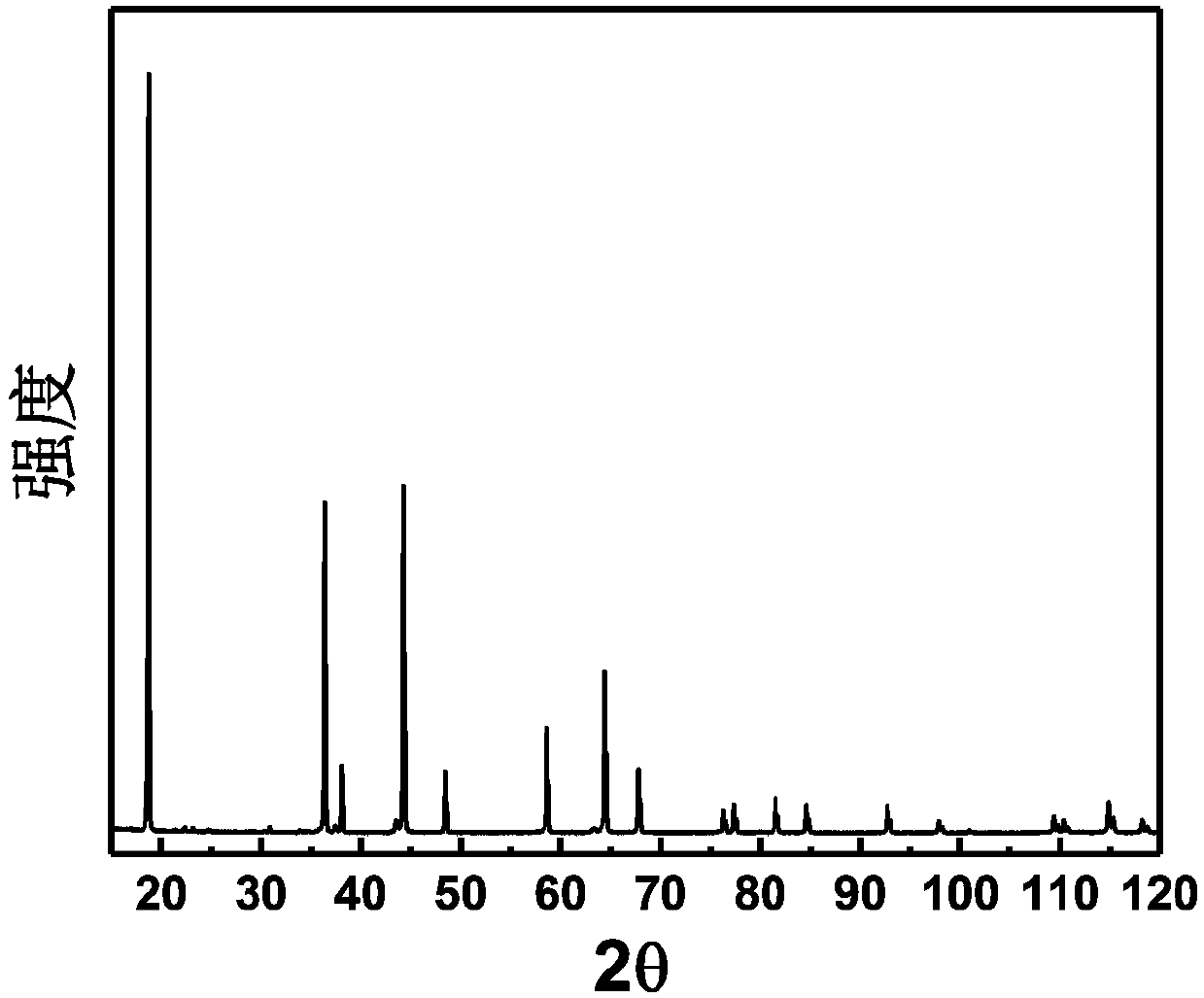

[0043] see figure 1 , X-ray powder diffraction a...

Embodiment 2

[0047] Add 0.06mol of citric acid to 100ml of deionized water, and after the citric acid is dissolved, add 0.043125mol of elemental manganese powder, 0.015mol of nickel acetate, 0.0315mol of lithium acetate and 0.0015mol of diammonium hydrogen phosphate; The solution was magnetically stirred at room temperature for 5 hours; the mixed solution was evaporated to dryness with magnetic stirring at a constant temperature of 80°C to obtain a precursor; the above precursor was pre-decomposed at 230°C for 4 hours, and the pre-decomposed product was ground to obtain a ground Product; the ground product is subjected to two-step heat treatment under air atmosphere conditions, the treatment conditions are 650 ° C for 10 h and 900 ° C for 2 h, and then cooled with the furnace to obtain a high-performance P non-equal doped nickel manganese oxide lithium ion battery positive electrode Material.

[0048] X-ray powder diffraction analysis shows that the product is a pure-phase lithium nickel m...

Embodiment 3

[0050] Add 0.10mol of citric acid to 100ml of deionized water, and after the citric acid is dissolved, add 0.043125mol of elemental manganese powder, 0.015mol of nickel acetate, 0.0315mol of lithium acetate and 0.0015mol of diammonium hydrogen phosphate; The solution was magnetically stirred at room temperature for 5 hours; the mixed solution was evaporated to dryness with magnetic stirring at a constant temperature of 80°C to obtain a precursor; the above precursor was pre-decomposed at 230°C for 4 hours, and the pre-decomposed product was ground to obtain a ground Product; the ground product is subjected to two-step heat treatment under air atmosphere conditions, the treatment conditions are 650 ° C for 10 h and 900 ° C for 2 h, and then cooled with the furnace to obtain a high-performance P non-equal doped nickel manganese oxide lithium ion battery positive electrode Material.

[0051] X-ray powder diffraction analysis shows that the product is a pure-phase lithium nickel m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com