Flexible all-solid-state battery and its preparation method

An all-solid-state battery, solid-state electrolyte technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc. Will drop, good anti-stretch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of a flexible all-solid-state battery, comprising the following steps:

[0038] (1) Mix and stir the positive active material, conductive adhesive, binder, first solid electrolyte, first cellulose matrix and solvent to form a uniformly dispersed slurry, and pour the obtained slurry into a suction filter with filter paper In the device, a membrane is formed by filtration, and a flexible positive electrode sheet is prepared.

[0039] (2) Mix and stir the negative electrode active material, the conductive adhesive, the binder, the first solid electrolyte, the first cellulose matrix and the solvent to form a uniformly dispersed slurry, and pour the obtained slurry into a suction filter with filter paper In the device, a membrane is formed by filtration to prepare a flexible negative electrode sheet;

[0040] (3) Fully mix and disperse the second solid electrolyte in the solvent at a high speed, and then add the secon...

Embodiment 1

[0049] (1) Put the active material graphite raw material, conductive agent carbon nanotubes, solid electrolyte polyethylene oxide, and nanocellulose matrix into isopropanol solvent in a mass ratio of 87:3:5:5, Stir at a high speed for 15 minutes at room temperature to obtain a viscous slurry, pour the obtained viscous slurry into a suction filtration device with filter paper, filter to form a film, and vacuum dry for 8 hours at a temperature of 130° to obtain a flexible negative electrode After rolling the dried flexible negative electrode sheet on a roller press, a flexible negative electrode sheet with a thickness of 100 microns was obtained.

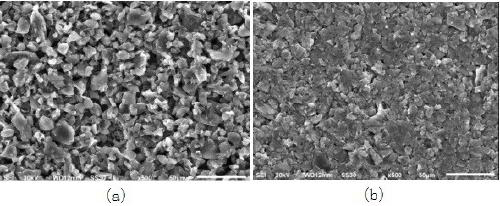

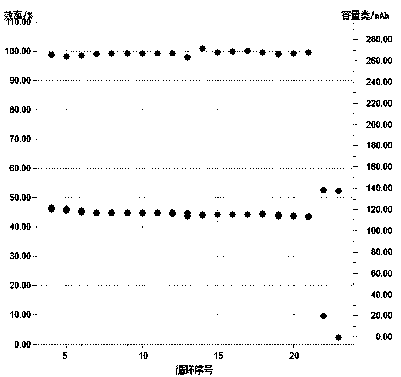

[0050] The flexible negative electrode sheet obtained in this example is as follows figure 1 As shown, the pole pieces are very flexible and can be bent repeatedly without breaking. figure 2 The electron microscope images of the flexible negative sheet before and after rolling. It can be seen from the figure that the active material...

Embodiment 2

[0056] (1) The active material lithium cobalt oxide raw material, conductive agent carbon nanotubes, solid electrolyte Li 6.4 La 3 Zr 1.4 Ta 0.6 O 12 The three substances were put into the isopropanol solvent in a mass ratio of 92:3:5, stirred at a high speed for 10min at room temperature to form a uniformly dispersed suspension, and the fully dispersed cellulose base solution was added to the suspension. , the cellulose accounts for 8% of the entire pole piece, stir again at high speed for 5 minutes to obtain a viscous slurry, pour the obtained viscous slurry into a suction filtration device with filter paper, filter to form a film, and at a temperature of 120 °. , vacuum dried for 12 hours to obtain a flexible positive electrode sheet, and after the dried flexible positive electrode sheet was rolled on a roller press, a flexible positive electrode sheet with a thickness of 110 microns was obtained.

[0057] The flexible positive electrode sheet obtained in this example i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com