Warehousing logistics robot control system based on MSP430

A control system and robot technology, applied in two-dimensional position/channel control and other directions, can solve problems such as descent, achieve the effect of realizing information exchange, improving battery voltage too low, and improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

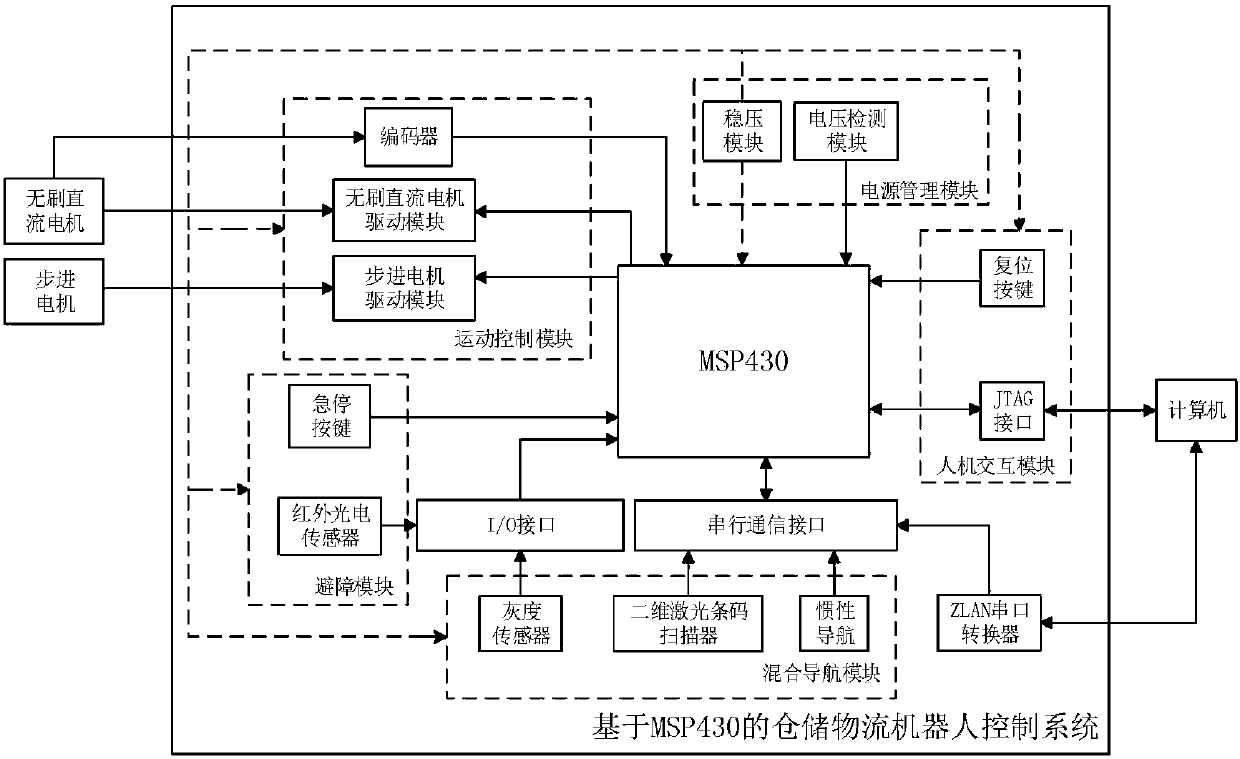

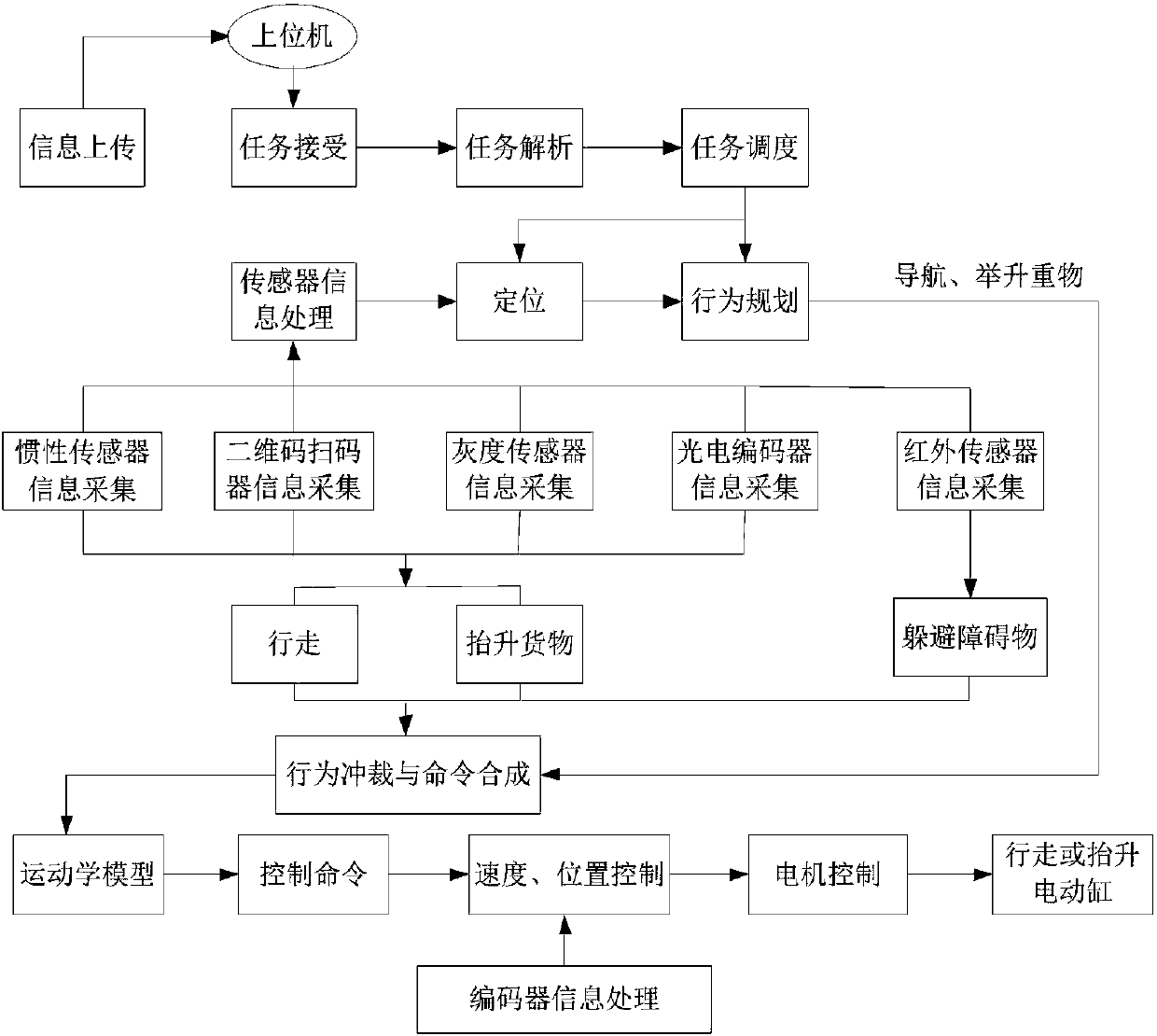

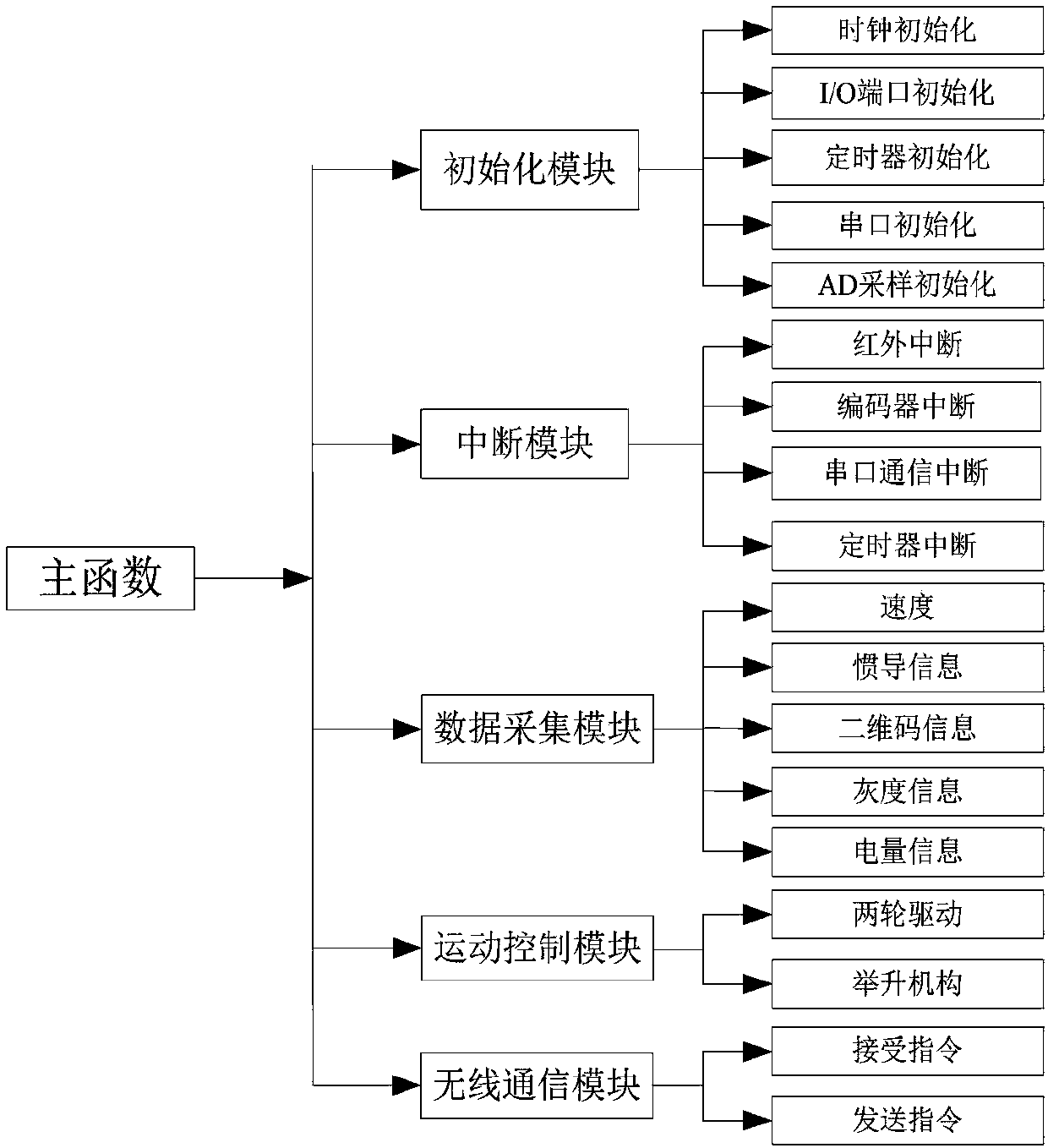

[0016] combine figure 1 , The present invention is a warehouse logistics robot control system based on MSP430, including a main control chip, a human-computer interaction module, a hybrid navigation module, an obstacle avoidance module, a power management module, a communication module and a motion control module. The motion control module includes an encoder, a brushless DC motor driver module and a stepper motor driver module; the obstacle avoidance module includes an emergency stop button and an infrared photoelectric sensor; the hybrid navigation module includes a grayscale sensor, a two-dimensional laser barcode Scanner and inertial navigation; the human-computer interaction module includes a reset button and a JTAG interface; the power management module includes a power supply, a voltage stabilization module and a voltage detection module. The hardware circuit of the control system is drawn by AD software and made into a PCB circuit board. The control system software is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com