Efficient annular vacuum coating device for fuel cell metal bipolar plate

A metal bipolar plate and vacuum coating technology, which is applied in vacuum evaporation coating, metal material coating process, sputter coating, etc. Applicable, without mentioning issues such as fuel cell bipolar plates, to achieve the effect of increasing the effective volume ratio, shortening the pumping time, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

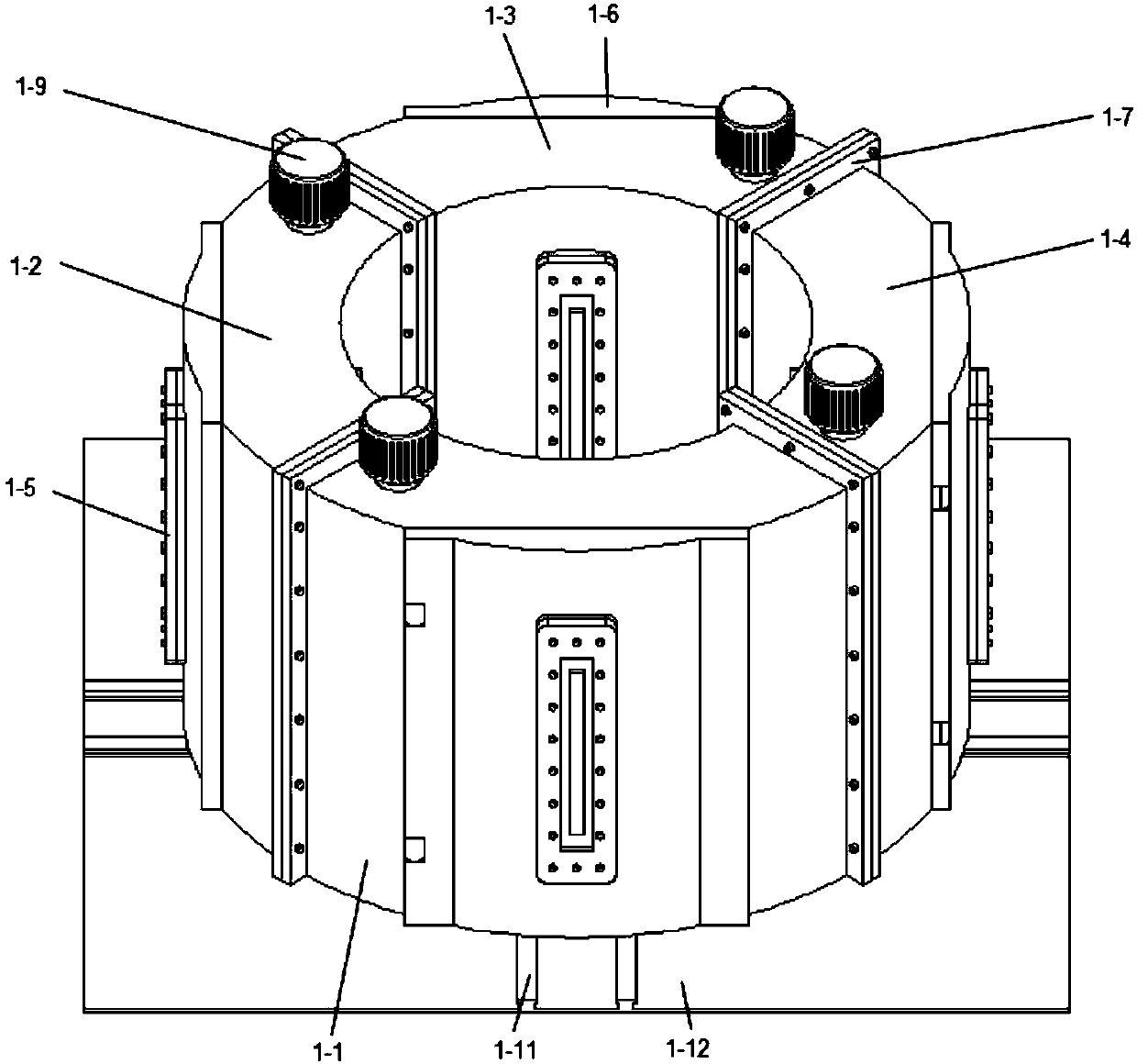

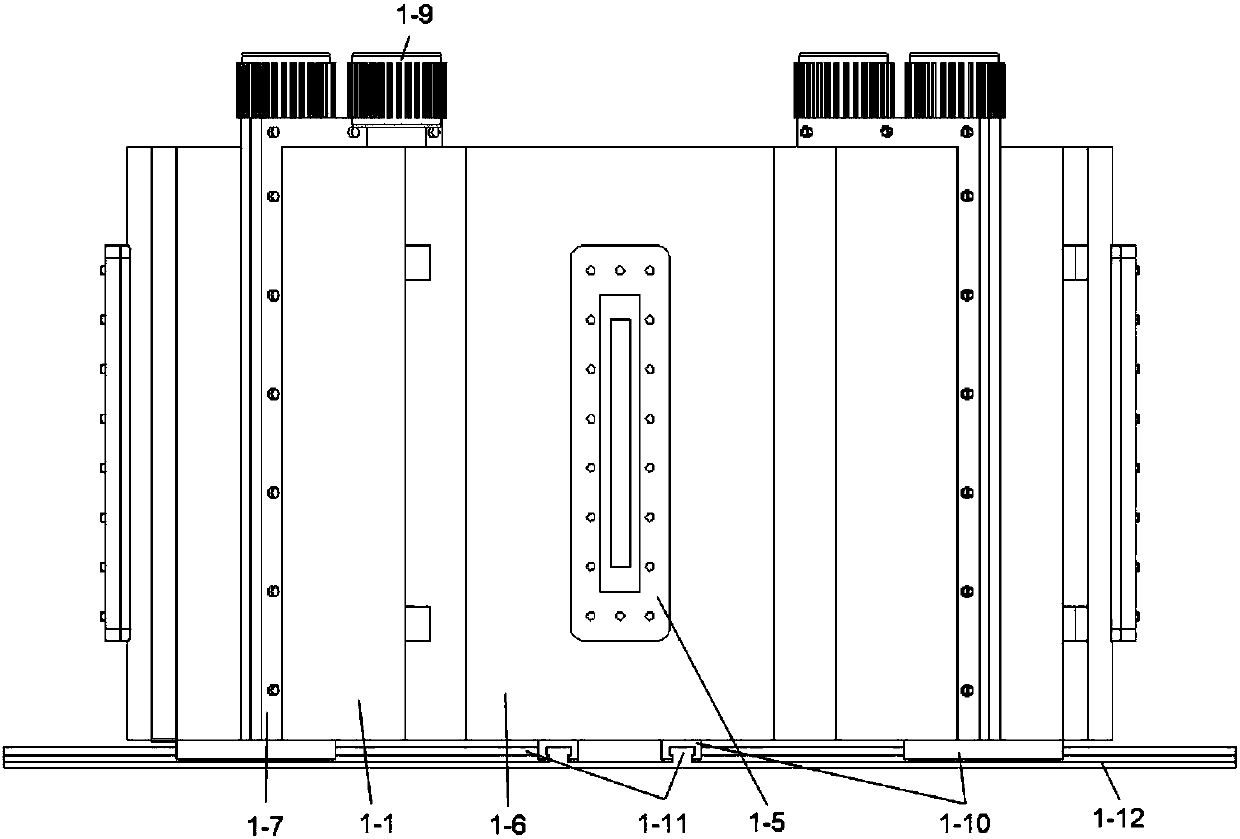

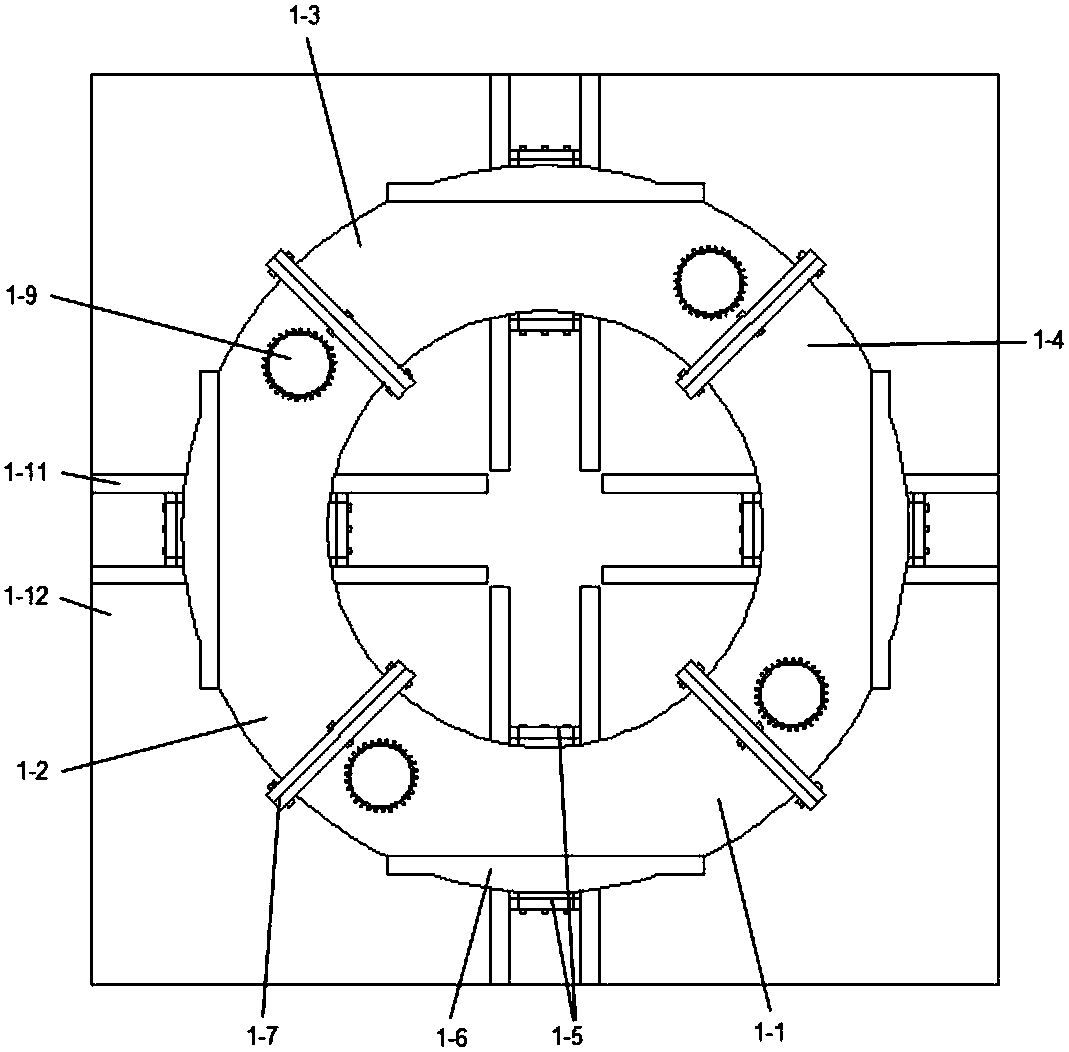

[0043] A fuel cell metal bipolar plate high-efficiency annular vacuum coating device, mainly composed of the first, second, third, and fourth sub-chambers for coating, sputtering cathode target material, workpiece rack and workpiece rack transmission mechanism, vacuum system, electric Control system, cooling system and other vacuum sputtering mechanisms.

[0044] The above-mentioned chamber, isolation plate and sputtering target, such as Figure 1~2 As shown, the first coating sub-chamber 1-1, the second coating sub-chamber 1-2, the third coating sub-chamber 1-3, the fourth coating sub-chamber 1-4, the cathode target 1-5, Sub-chamber airtight door 1-6, connecting flange 1-7, slit isolation plate 1-8, air pump 1-9, sub-chamber bottom guide rail 1-10, etc. The inner diameter of the chamber is 1200-1600mm, the outer diameter is 2000-2400mm, and the height is 1000-1500mm. Wherein each sub-chamber is provided with independent airtight door 1-6 respectively, when this sub-chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com