A Reentrant Cavity Sensor for Measuring Permittivity and Permeability of Magnetic Media Materials

A dielectric constant and sensor technology, applied in the field of sensors, can solve the problems of magnetic material errors, multi-functional sensors with poor separation effect of electric field and magnetic field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to better describe the design process and purpose, the present invention will be further described below in conjunction with the embodiments and accompanying drawings:

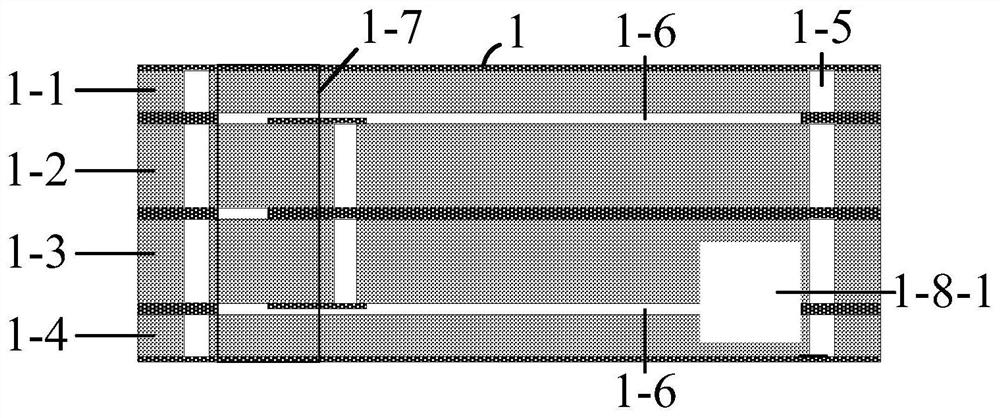

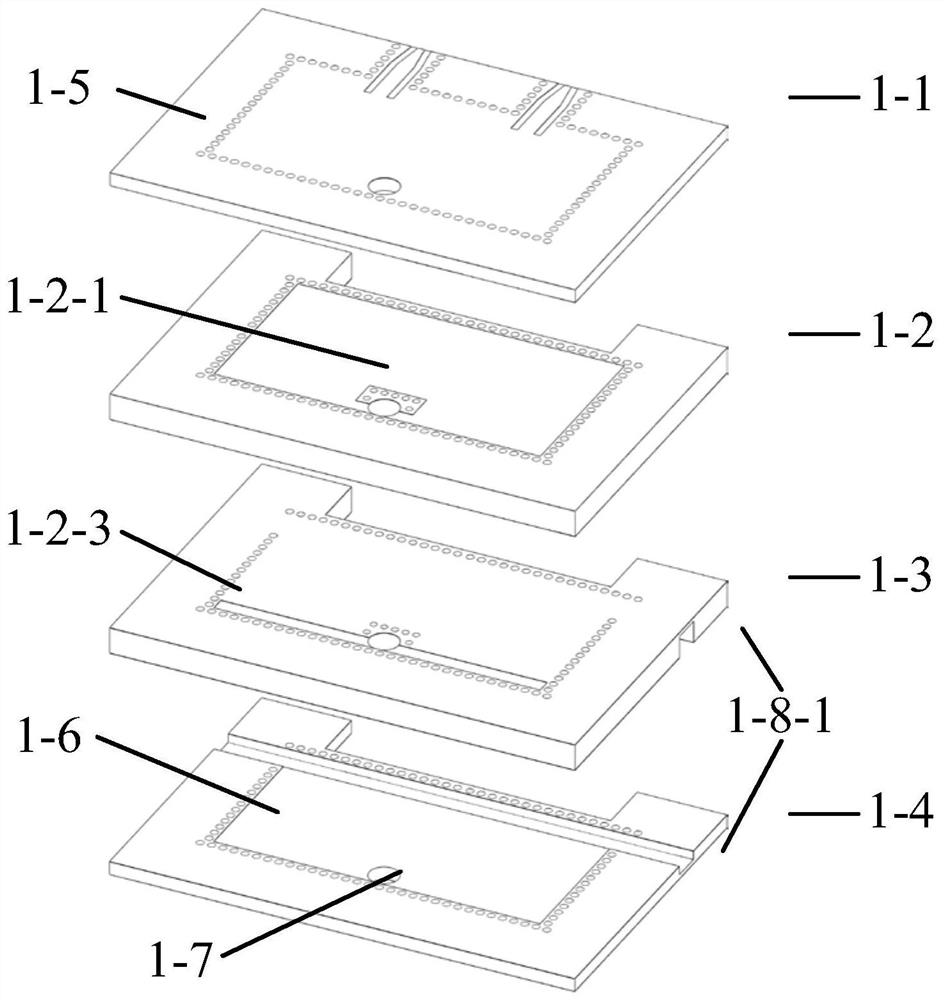

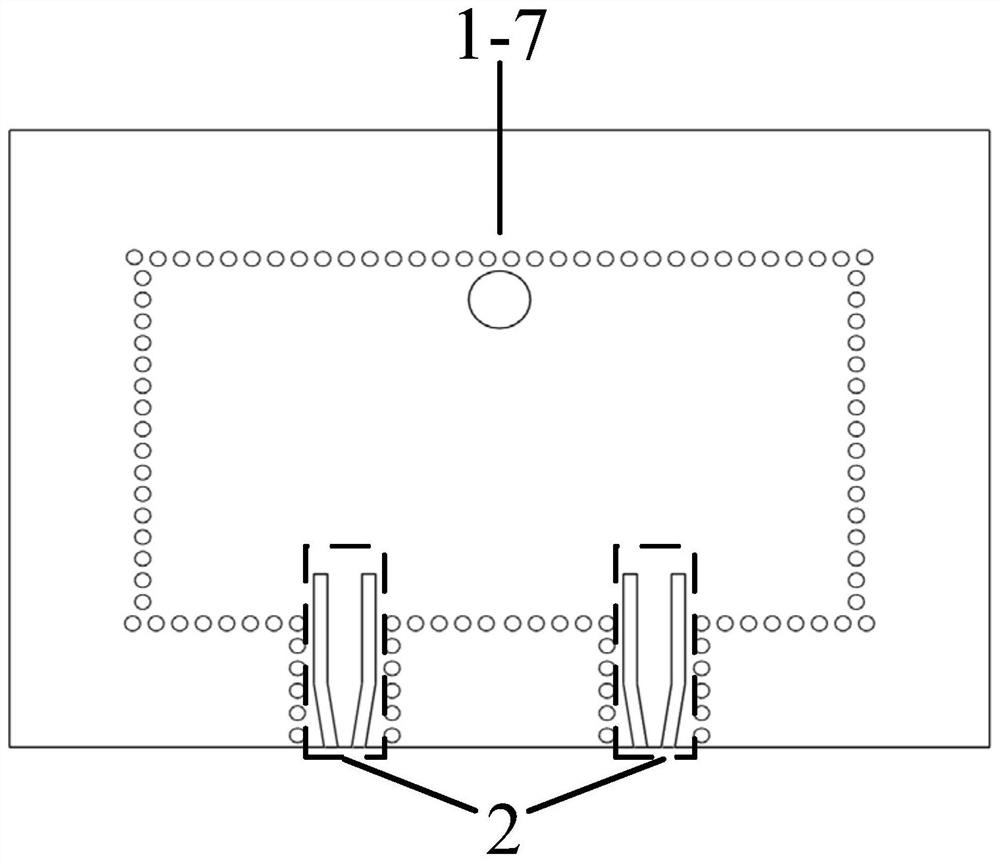

[0045] Such as figure 1 As shown in Figure 6(a) and Figure 6(b), the reentrant cavity sensor proposed by the present invention for measuring the permittivity and permeability of magnetic media materials includes a resonant cavity (1) and two coplanar Waveguide feeder (2). The entire sensor consists of four vertically stacked dielectric substrates to form a sensor base, and each dielectric substrate has a three-layer structure of a top metal layer, a middle dielectric layer and a bottom metal layer. The resonant cavity (1) is formed between the first dielectric substrate (1-1) and the second dielectric substrate (1-2), the third dielectric substrate (1-3) and the fourth dielectric substrate (1-4) .

[0046] The intermediate dielectric layer materials of the first dielectric substrate (1-1), t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com