Mould-proof sealant and preparation method thereof

A sealant and anti-mildew technology, applied in the field of sealant, can solve the problems of loss of anti-mildew function, black, yellow, green, and low shelf life on the surface of the colloid, so as to solve the dead angle of household hygiene and overcome the anti-mildew effect. Poor, high storage stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method of the above-mentioned mildew-proof sealant, comprising the following steps:

[0031] Add silane-modified polyether mixture, vinyltrimethoxysilane, and stabilizer to the glue making machine and stir at low speed for 5 minutes, then add filler and titanium dioxide and stir at low speed for 10 minutes, then add rheological agent and stir at low speed for 5 minutes, vacuumize and stir at high speed for 10 minutes, Finally, add the adhesion promoter and vacuumize and stir at low speed for 10 minutes to obtain the anti-mildew sealant.

[0032] Here, the silane-modified polyether mixture, filler, vinyltrimethoxysilane, rheology agent, phototitanium dioxide, stabilizer, and adhesion promoter are all the same as above, and will not be repeated here.

[0033] In the above technical scheme, the method is simple, the prepared anti-mold sealant is simple to prepare, has excellent anti-mold effect and high storage stability, a...

Embodiment 1

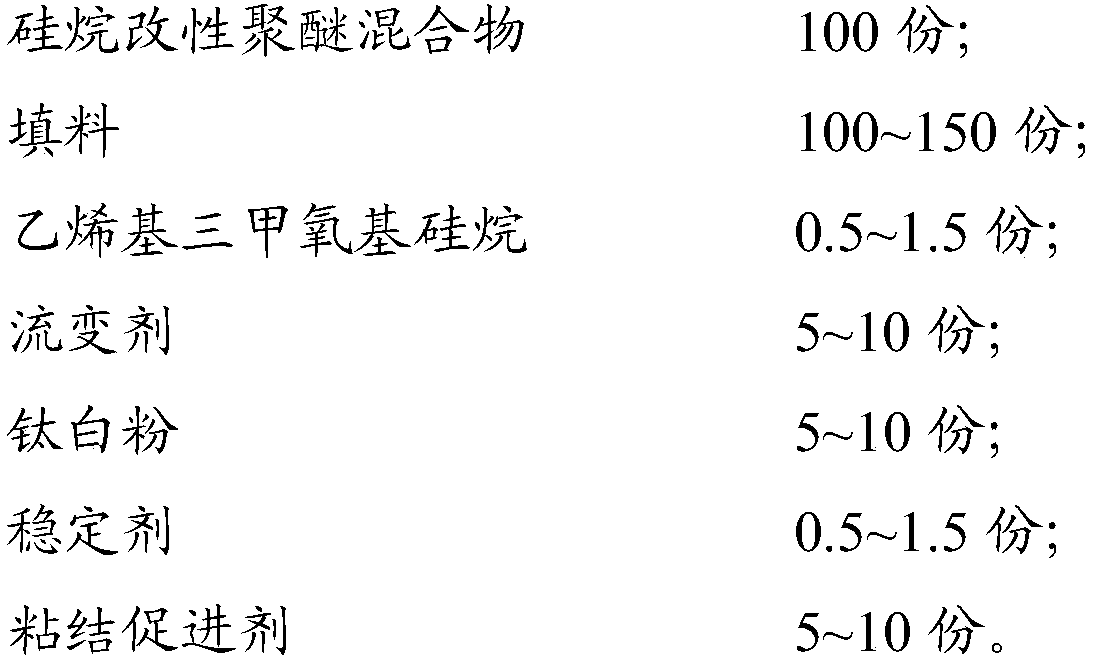

[0037] The anti-mildew sealant includes the following raw materials in parts by weight:

[0038] 20 parts dimethoxysilyl urethane terminated polyether, 40 parts polyether terminated hybrid polymer, 100 parts filler, 0.5 parts vinyltrimethoxysilane, 5 parts rheological agent, 10 parts Phototitanium dioxide, 0.5 parts of stabilizer, 5 parts of adhesion promoter;

[0039] The preparation method of mildew-proof sealant comprises the following steps:

[0040] Add silane-modified polyether mixture, vinyltrimethoxysilane, and stabilizer to the glue making machine and stir at low speed for 5 minutes, then add filler and titanium dioxide and stir at low speed for 10 minutes, then add rheological agent and stir at low speed for 5 minutes, vacuumize and stir at high speed for 10 minutes, Finally, add the adhesion promoter and vacuumize and stir at low speed for 10 minutes to obtain the anti-mildew sealant.

[0041] During the two vacuum stirring processes, the vacuum degree of the glue...

Embodiment 2

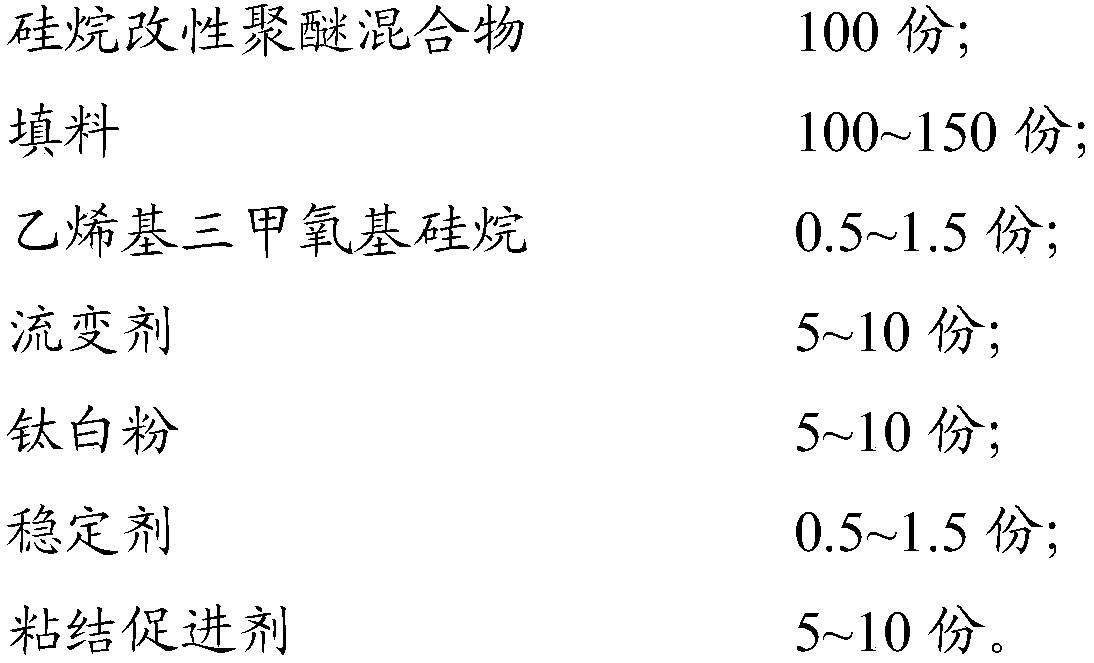

[0043] The anti-mildew sealant includes the following raw materials in parts by weight:

[0044] 20 parts dimethoxysilylmethyl carbamate terminated polyether, 40 parts polyether terminated hybrid polymer, 150 parts filler, 0.8 part vinyltrimethoxysilane, 6 parts rheological agent, 7 parts Phototitanium dioxide, 1.5 parts of stabilizer, 10 parts of adhesion promoter;

[0045] The preparation method of mildew-proof sealant comprises the following steps:

[0046] Add silane-modified polyether mixture, vinyltrimethoxysilane, and stabilizer to the glue making machine and stir at low speed for 5 minutes, then add filler and titanium dioxide and stir at low speed for 10 minutes, then add rheological agent and stir at low speed for 5 minutes, vacuumize and stir at high speed for 10 minutes, Finally, add the adhesion promoter and vacuumize and stir at low speed for 10 minutes to obtain the anti-mildew sealant.

[0047] During the two vacuum stirring processes, the vacuum degree of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com