Butyl rubber reactive bonding layer used for pre-paving reactive-bonding waterproofing coiled material, preparation method thereof, and the pre-paving reactive-bonding waterproofing coiled material

A waterproof membrane and reactive adhesive technology, which is applied in the direction of adhesives, layered products, polymer adhesive additives, etc., can solve the problems of inconvenient identification of leaking points, easy flow, and restrictions on the application fields of pre-laid reactive adhesive membrane construction, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0140] According to a second aspect of the present invention, there is provided a method for preparing the above-mentioned butyl glue reactive adhesive layer for pre-laying reactive adhesive waterproof membrane, comprising the following steps:

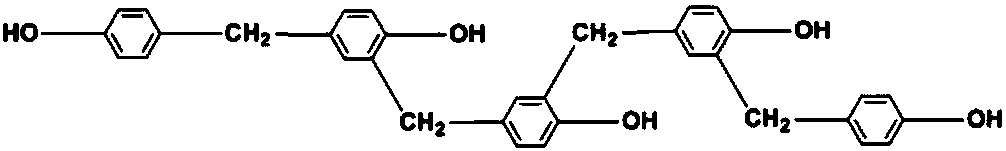

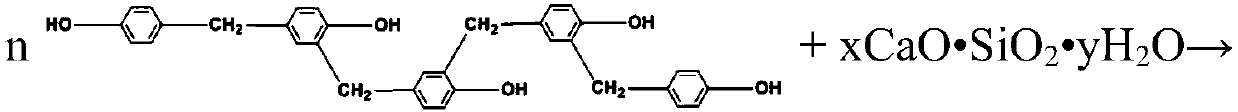

[0141] (a) mix raw rubber with 50-60% of the linear tackifying resin containing terminal hydroxyl structure, the active filler of the formula weight and optional terpene resin, petroleum resin, nano-calcium carbonate, processing aid according to the formula weight additives, inorganic dyes, anti-aging agents and anti-ultraviolet absorbers for banburying;

[0142] (b) After cooling down, continue banburying and molding with the linear tackifying resin containing terminal hydroxyl structure of the remaining formula weight and optional crosslinking agent and reactive auxiliary agent to obtain a butyl rubber reaction adhesive layer.

[0143] The types and sources of the raw materials for the preparation of the butyl rubber reaction adhesiv...

Embodiment 1

[0165] A butyl rubber reaction adhesive layer, consisting of the following raw materials in parts by weight: 100 parts of butyl rubber, 9.5 parts of polyamide-modified novolac resin, 1 part of terpene resin, 5 parts of petroleum resin, and 50 parts of nano-calcium carbonate 12.5 parts of active filler, 10 parts of dioctyl phthalate, 5 parts of titanium dioxide, 1 part of anti-aging agent RD, 1 part of anti-ultraviolet absorber UV-P, 0.5 part of sulfur and 1 part of sodium carboxylate.

[0166] Processing technology: Put butyl rubber in an internal mixer according to the formula weight, process it for 5 minutes at a temperature of 105°C and a speed of 60r / min, and then alternately add terpene resin, petroleum resin, nano-calcium carbonate, Active filler, dioctyl phthalate, titanium dioxide, anti-aging agent RD and anti-ultraviolet absorber UV-P and the polyamide-modified novolac resin of formula weight 60%, banburying 10min, to mixing; The temperature drops to 70°C, add polyami...

Embodiment 2

[0168] A butyl rubber reaction adhesive layer, consisting of the following raw materials in parts by weight: 60 parts of butyl rubber, 40 parts of brominated butyl rubber, 4.5 parts of polyamide-modified novolac resin, epoxy-modified novolak 6.5 parts of phenolic resin, 3 parts of terpene resin, 6 parts of petroleum resin, 80 parts of nano-calcium carbonate, 16 parts of active filler, 20 parts of paraffin oil, 5 parts of iron oxide blue, 1 part of antioxidant 4010NA, anti-ultraviolet absorber UVP- 327 1 part, p-benzoquinone dioxime 0.5 part and sodium citrate 1 part.

[0169] Processing technology: Put butyl rubber and bromobutyl rubber in an internal mixer according to the formula weight, process at a temperature of 105°C and a speed of 60r / min for 8 minutes, then add terpene resin and petroleum in three times alternately Resin, nano-calcium carbonate, active filler, paraffin oil, iron oxide blue, antioxidant 4010NA and anti-ultraviolet absorber UVP-327 and the polyamide-modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com