Preparation method of superfine powder of rhizome of conic gymnadenia

A technology of ultra-fine powder and palm ginseng, which is applied in medical preparations containing active ingredients, powder delivery, pharmaceutical formulations, etc., can solve the problems of low bioavailability, natural odor, inconvenience in taking, etc. High yield, high powder yield, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

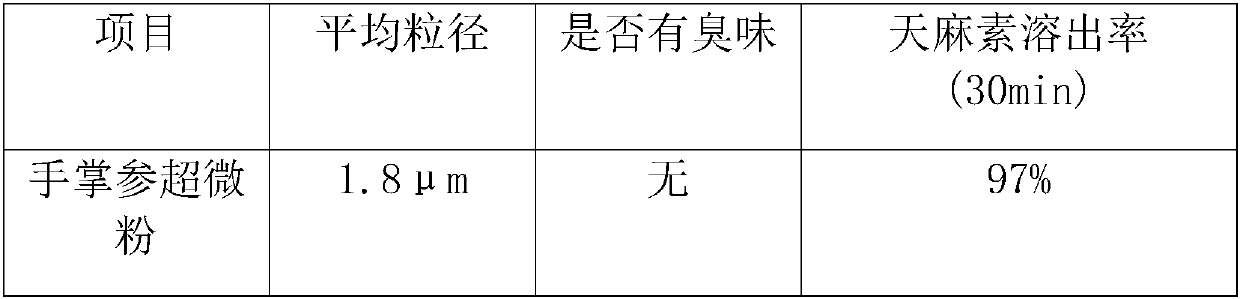

[0020] Take 1Kg of fresh palm ginseng, add 3Kg of ultrapure water and ultrasonically clean it for 30 minutes, the ultrasonic power is 200w, and the temperature is 30°C; use a solution of baking soda solution with a concentration of 78g / L to soak for 12 hours, and air-dry the surface moisture after cleaning; use a microwave vacuum drying oven Dry at 50°C for 6 hours, the moisture content measured by the infrared moisture analyzer is 4%, and 500g of dry material is obtained; the universal pulverizer is pulverized twice, each time for 2min, and passed through a 7-mesh sieve, the coarse powder yield is 100%; Type planetary ball mill pulverization, rotating speed 1500rpm, pulverization 2 times, each time 1min, interval 1min. Finally get superfine powder 480g. Detect particle size, use ultraviolet light spectrophotometer to measure and calculate gastrodia elata dissolution rate, obtain following table:

[0021]

Embodiment 2

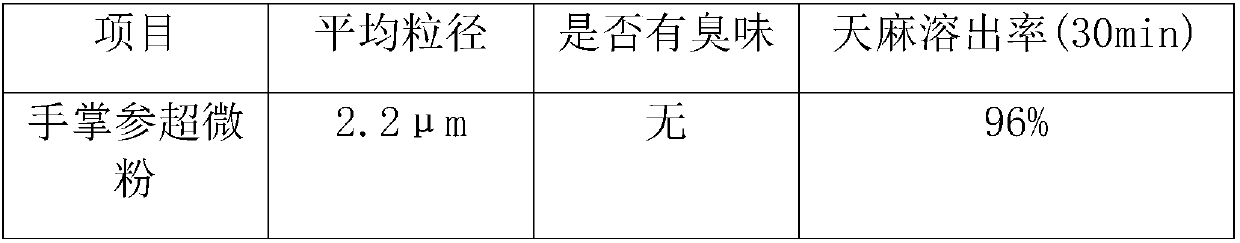

[0023] Take 500g of dried ginseng palm, add 2Kg of ultrapure water and ultrasonically clean it for 30min, the ultrasonic power is 200w, and the temperature is 30°C; use a sodium bicarbonate solution with a concentration of 78g / L to soak for 12h, and air-dry the surface moisture after cleaning; use a microwave vacuum drying oven Dry at 50°C for 6 hours, the moisture content measured by the infrared moisture analyzer is 4%, and 490g of dry material is obtained; the universal pulverizer is crushed twice, each time for 2 minutes, and passed through a 7-mesh sieve, the coarse powder yield is 100%; continue to use the air flow Pulverize with a pulverizer, the rotation speed is 2000rpm, and the temperature is 10°C. Finally get superfine powder 460g. Detect particle size, use ultraviolet light spectrophotometer to measure and calculate gastrodia elata dissolution rate, obtain following table:

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com